Resin composition

A technology of resin composition and compound, applied in the direction of epoxy resin glue, adhesive type, adhesive additive, etc., can solve the problem of insufficient PCT resistance, etc., and achieve the effect of excellent PCT resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0082] Hereinafter, the present invention will be described in detail using examples. However, the present invention is not limited to these Examples.

[0083] (Preparation of resin composition)

[0084] Resin compositions were prepared by mixing the respective components according to the compounding ratios shown in Tables 1 to 12 below. In addition, in Tables 1-12, the figure which shows the compounding ratio of (A) component - (F) component all shows a mass part.

[0085] Each component in Tables 1-10 is as follows.

[0086] (A) Ingredients

[0087] EXA835LV: Bisphenol F type epoxy resin - bisphenol A type epoxy resin mixture (manufactured by DIC Corporation, epoxy equivalent 165)

[0088] YDF8170: bisphenol F epoxy resin (manufactured by Nippon Steel Chemical Co., Ltd., epoxy equivalent 160)

[0089] ZX1658GS: Cyclohexanedimethanol diglycidyl ether (manufactured by Nippon Steel Chemical Co., Ltd., epoxy equivalent 135)

[0090] (B) Ingredients

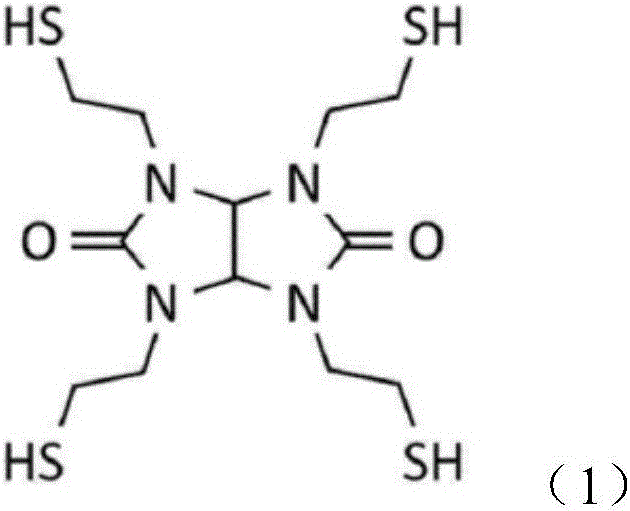

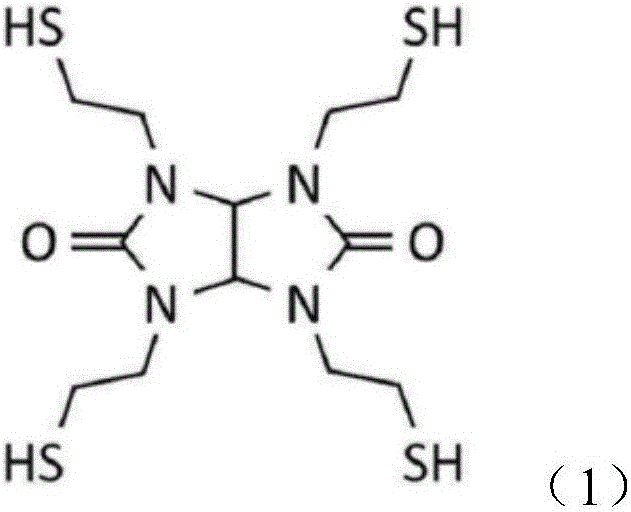

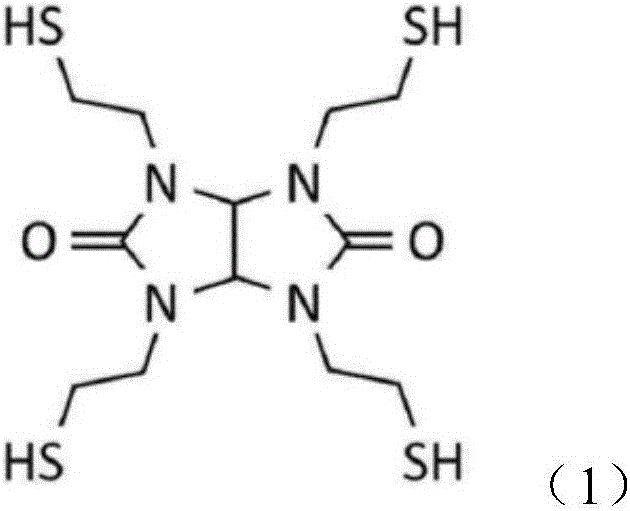

[0091] TS-G: a compou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| residual percentage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com