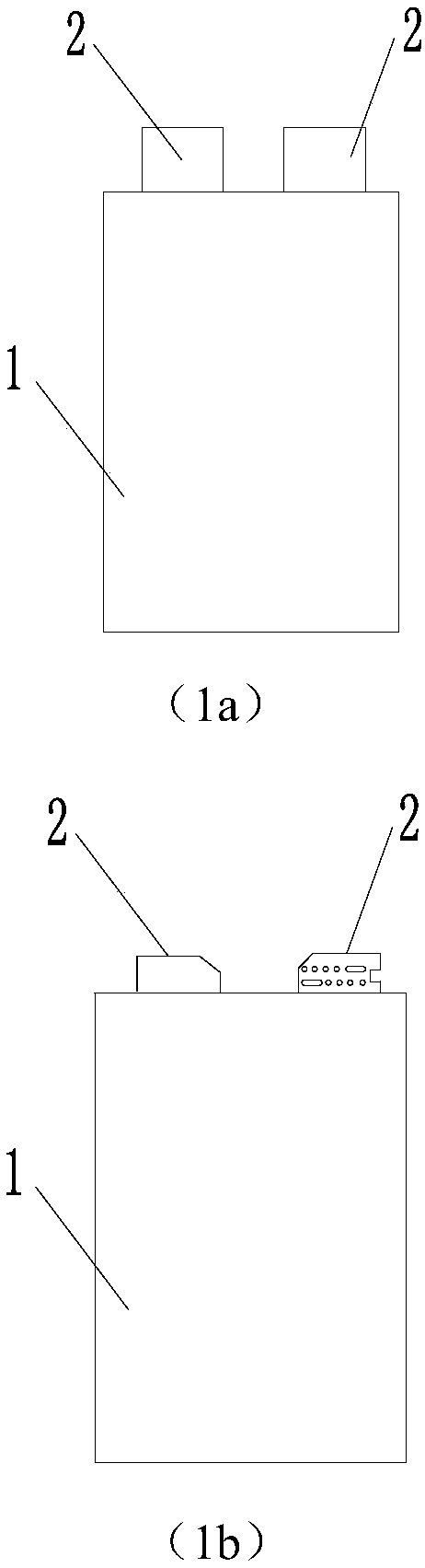

A multi-station turntable battery automatic punching machine

An automatic punching machine and turntable technology, which is applied to circuits, electrical components, metal processing, etc., can solve the problems of lack of applicable literature, inability to ensure the high consistency of tabs, and lack of real-time detection links for cell punching technology. Achieve the effect of ensuring the consistency of punching dimensions, compact structure and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

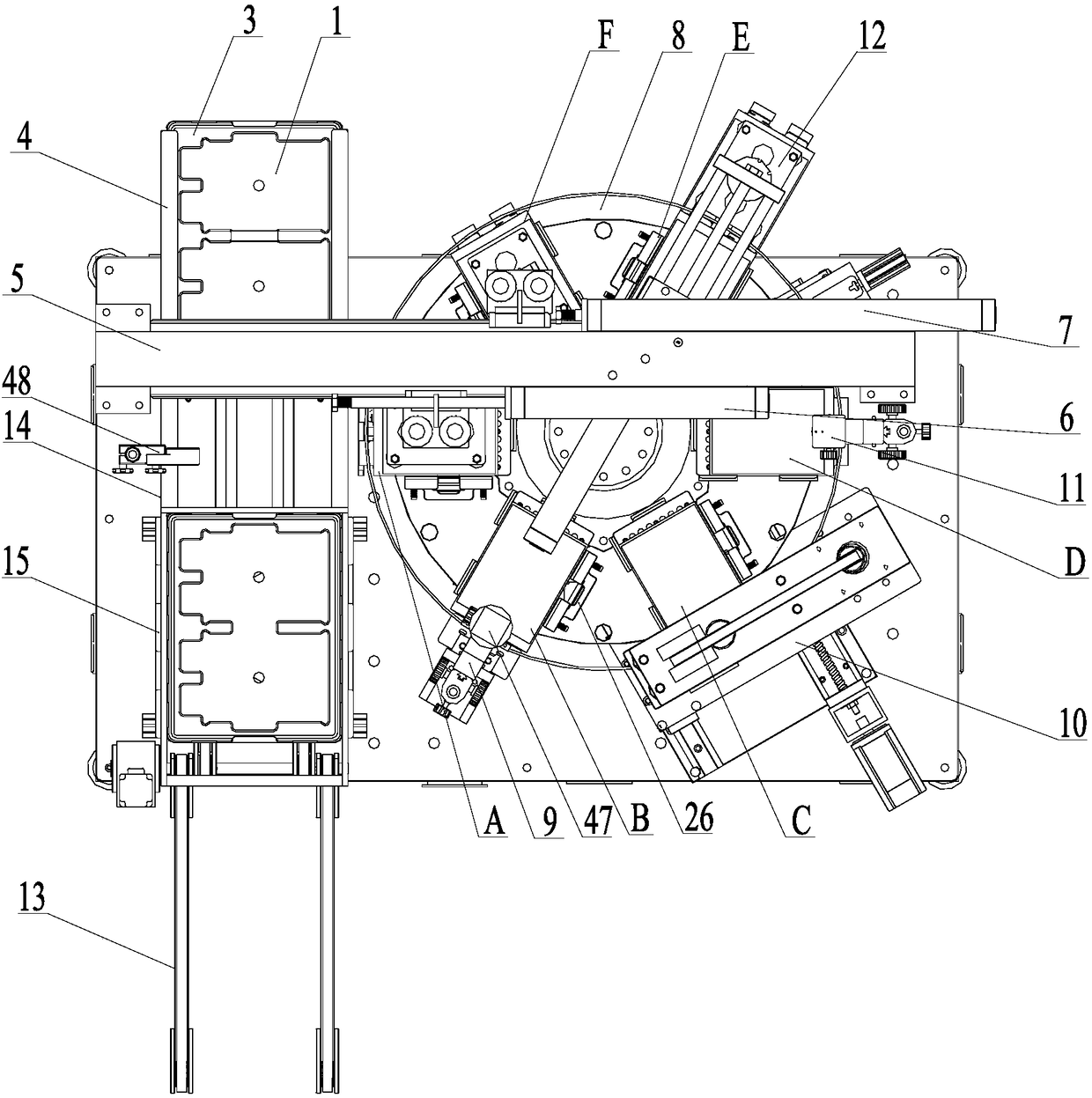

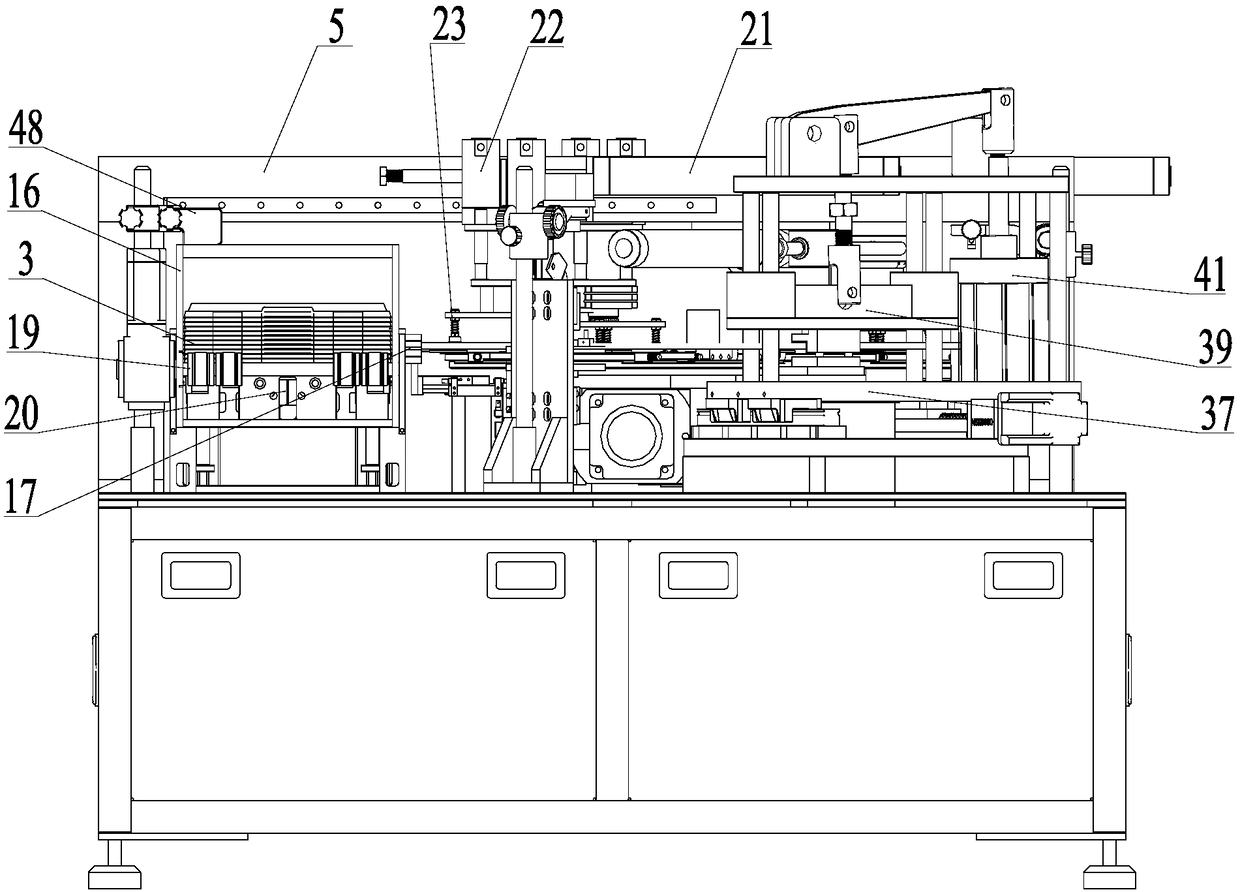

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

[0043] like Figure 2-5 As shown, a multi-station turntable type battery automatic punching machine includes a transmission mechanism 4, a bracket 5, a feeding mechanism 6, a qualified product blanking mechanism 7, a working turntable 8, a voltage measuring mechanism 9, a punching mechanism 10, Backward image detector 11, defective product unloading mechanism 12, forward image detector 47 and code reader 48, working turntable 8 is set on one side of transmission mechanism 4, bracket 5 is erected on the side of working turntable 8 and transmission mechanism 4 On the top, the retrievin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com