Fluorescent film for backlight module and manufacturing method of fluorescent film

A backlight module and fluorescence technology, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of quantum dot luminous efficiency quenching, reduce the high color gamut and stability of quantum dot film display, and improve luminous efficiency And stability, improve luminous stability, improve the effect of brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 0.1g of red CdS quantum dots with a particle size of 5nm, and add 0.9g of green CdTe quantum dots with a particle size of 1nm into a saturated solution containing 4.0g of sodium chloride for recrystallization to obtain mixed crystals of quantum dots. Grind to obtain mixed crystals with a particle size of 10 nm. Weigh 0.5g of quantum dot mixed crystals, add 3.5g of polystyrene diffusion particles with a particle size of 3μm to 96.0g of acrylic resin and mix thoroughly, and then coat the upper surface of the barrier film layer with a thickness of 30μm. The upper surface is compounded with an upper barrier film layer, and cured by ultraviolet light to obtain a fluorescent film with a thickness of 100 μm.

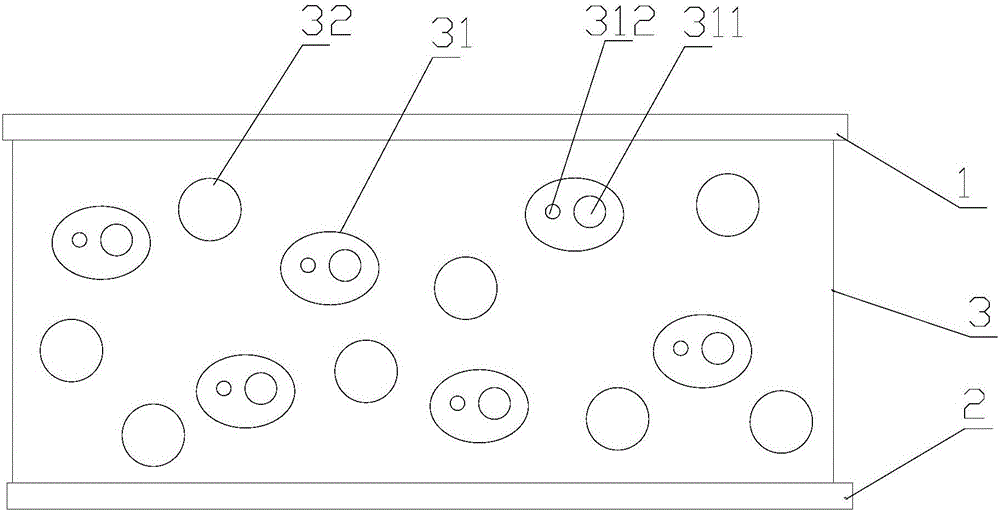

[0024] Such as figure 1 Shown is the structural diagram of the fluorescent film prepared by the above method. Described fluorescent film comprises barrier film layer one 1, barrier film layer two 2 and quantum dot layer 3, and quantum dot layer 3 is arranged betw...

Embodiment 2

[0026] Weigh 0.5g of red CdSe / ZnS quantum dots with a particle size of 9nm, and add 0.5g of green InP quantum dots with a particle size of 4nm into a saturated solution containing 9.0g of sodium citrate for recrystallization to obtain mixed crystals of quantum dots. Fully grind to obtain mixed crystals with a particle size of 40nm. Weigh 10.0g of quantum dot mixed crystals, add 5.0g of titanium dioxide diffusion particles with a particle size of 35μm into 85.0g of polyurethane resin and mix thoroughly, and then apply it on the upper surface of the barrier film layer with a thickness of 100μm. Composite the upper barrier film layer, and UV-cured to obtain a fluorescent film with a thickness of 300 μm.

[0027] The structure of the fluorescent film prepared by the above method is as follows: figure 1 shown.

Embodiment 3

[0029] Weigh 0.6g of red CdSe / ZnS quantum dots with a particle size of 7nm, and add 2.4g of green CdSe / ZnS quantum dots with a particle size of 3nm into a saturated solution containing 17.0 mg of magnesium sulfate for recrystallization to obtain quantum dot mixed crystals , fully ground to obtain mixed crystals with a particle size of 20nm. Weigh 2.0g of quantum dot mixed crystals, add 12.0g of polymethyl methacrylate diffusion particles with a particle size of 10 μm to 86.0 g of polystyrene resin and mix thoroughly, and then apply it on the upper surface of the barrier film layer with a thickness of 50 μm. The upper surface of the quantum dot coating solution is compounded with an upper barrier film layer, and cured by ultraviolet light to obtain a fluorescent film with a thickness of 200 μm.

[0030] The structure of the fluorescent film prepared by the above method is as follows: figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com