Single-tube resolution testing device of low-light level image intensifier

A low-light image intensifier and resolution technology, which is used in optical instrument testing, machine/structural component testing, measuring devices, etc., to achieve the effects of humanized operation, saving testing time, and simple and reasonable structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

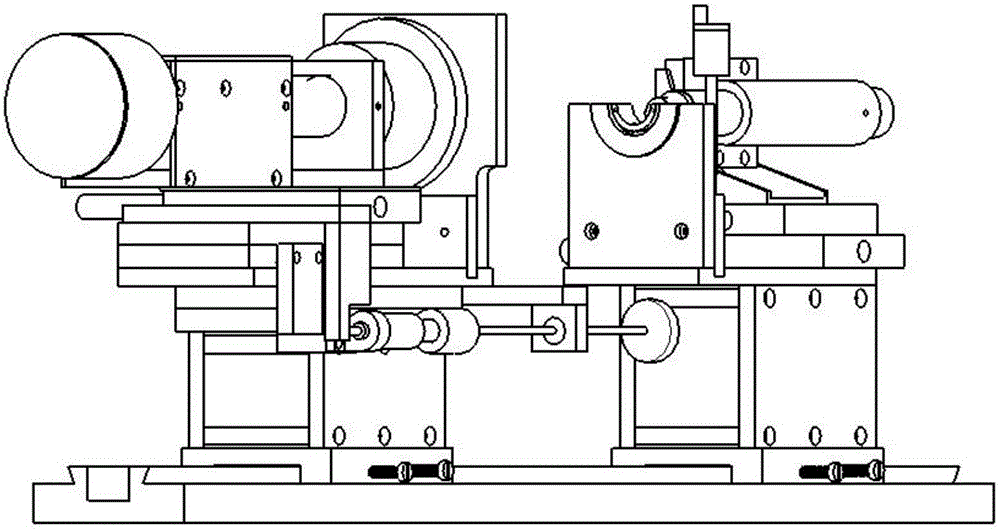

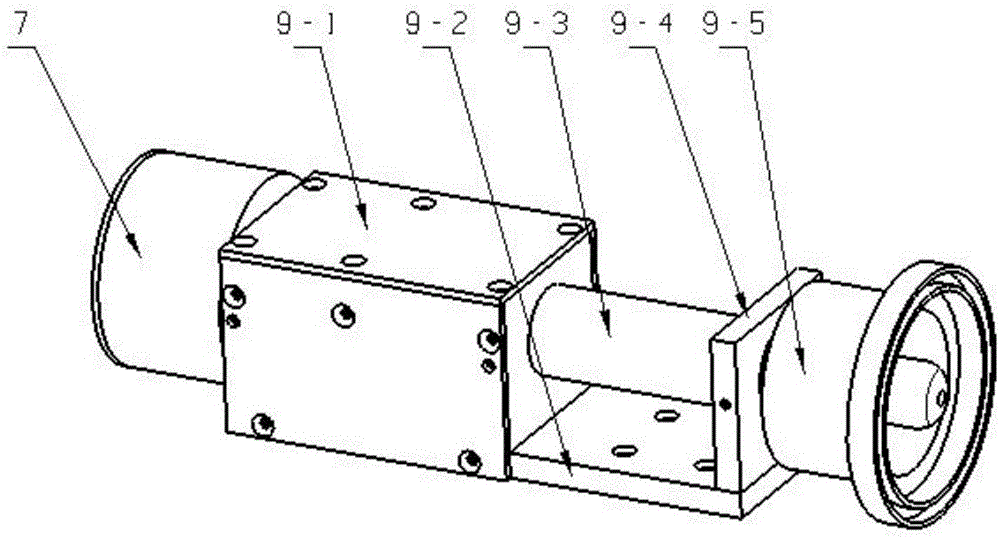

[0011] In combination with Fig. 1(a)(b), a super second-generation low-light image intensifier image tube single-tube test device includes an optical rail 1, and the left sliding base connected to the optical rail 1 includes a left slider 2 and a left support seat 3. The right sliding base 19; the left mechanical adjustment module connected to the top of the support base 3 includes from bottom to top: image tube clamping displacement adjustment platform 4, left transition plate 5, displacement adjustment module 6 in the X-axis direction, and Y-axis The displacement adjustment platform 8; the light source uniform attenuation and object image projection module 9 connected to the Y-axis displacement adjustment platform 8; the light source 7 connected to the light source uniform attenuation and object image projection module 9; the left image tube fixture connected to the left transition plate 5 10; the right transition plate 18 connected to the right sliding base 19; the right mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com