Energy-saving and environment-friendly two-circuit parallel type smoke waste heat recycling device and method

A flue gas waste heat, energy saving and environmental protection technology, applied in the direction of reduction of greenhouse gases, climate sustainability, lighting and heating equipment, etc., can solve certain effects of combustion conditions, easily damaged waste heat recovery devices, inconvenient boiler maintenance and cleaning, etc. problems, to achieve the effect of improving heat utilization, improving dust removal effect, improving stability and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

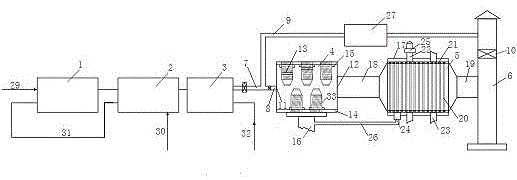

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] An energy-saving and environment-friendly double-circuit parallel flue gas waste heat recovery device, comprising a heating furnace 1, a heat exchanger 2, a boiler 3, a dust settling chamber 4, a waste heat recovery device 5 and a vertical chimney 6, wherein the heat exchange The two ends of the device 2 are respectively connected with the heating furnace 1 and the boiler 3, and the boiler 3 is provided with a flue gas output pipe 7, and the flue gas output pipe 7 is respectively connected with a first branch pipe 8 and a second branch pipe 9;

[0028] One side of the dust settling chamber 4 is provided with a smoke inlet 11, and the other side is provided with a smoke outlet 12. The smoke inlet 11 is connected to the first branch pipe 8, and several guide pipes are arranged in the dust settling chamber 4. Flow plate 33, the plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com