Honeycomb pore profiled steel sheet bidirectional overlapped floor slab

A technology of superimposed floor slabs and hole pressure type, which is applied in the direction of floors, building components, buildings, etc., can solve the problems that it is difficult to achieve the mechanical characteristics of cast-in-place two-way slabs, the overall seismic resistance of floors is unfavorable, and the thickness of laminated slabs is large. Reduce the work of laying steel bars, increase the effective use of space, and reduce the effect of self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

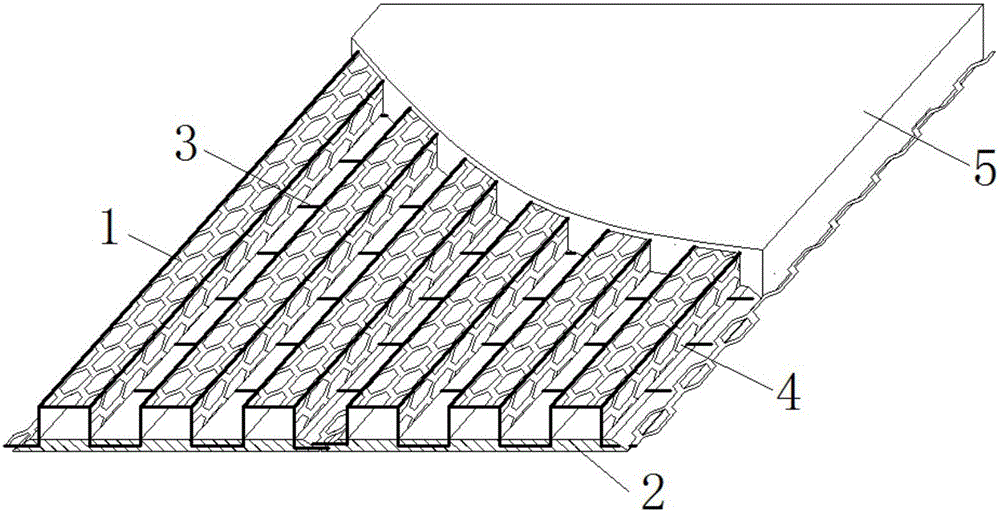

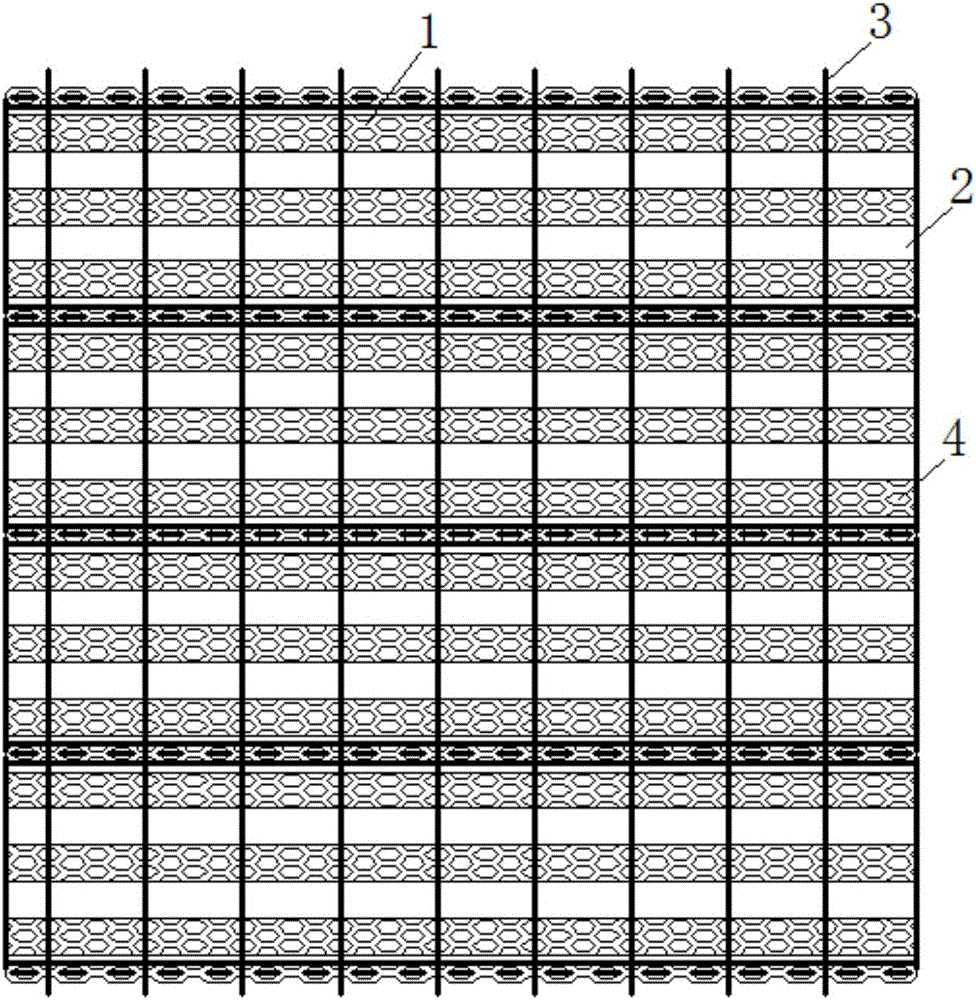

[0029] Such as figure 1 with figure 2 As shown, the two-way laminated floor slab of the honeycomb-hole profiled steel plate of the present invention comprises a plurality of honeycomb-hole profiled steel plates-concrete prefabricated floor slabs and cast concrete layers 5 after splicing;

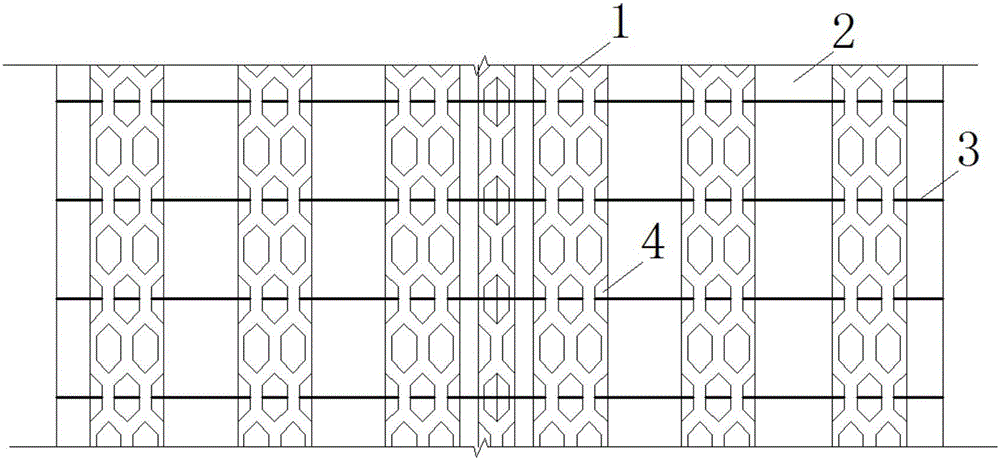

[0030] The honeycomb-hole profiled steel plate-concrete prefabricated floor includes a honeycomb-hole profiled steel plate 1 with flanges on both sides and a concrete bottom plate 2, and the honeycomb-hole profiled steel plate 1 is a corrugated thin steel plate bent into the shape of "several" , both sides of the honeycomb profiled steel plate 1 are provided with lower flanges, the distance between the lower flange of the honeycomb profiled steel plate 1 and the base plate is not less than the thickness of the concrete base plate 2, and the honeycomb profiled steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com