A Disperse Bath Dyeing Process of Polyester Cotton Microcapsule Disperse Dyes

A technology of disperse dyes and microcapsules, applied in the field of printing and dyeing, can solve the problems of unsatisfactory dyeing effect, fading effect of other clothing, unusable use, etc., and achieve the effect of good dyeing promotion effect, maintaining color and lustre, and stable reducing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

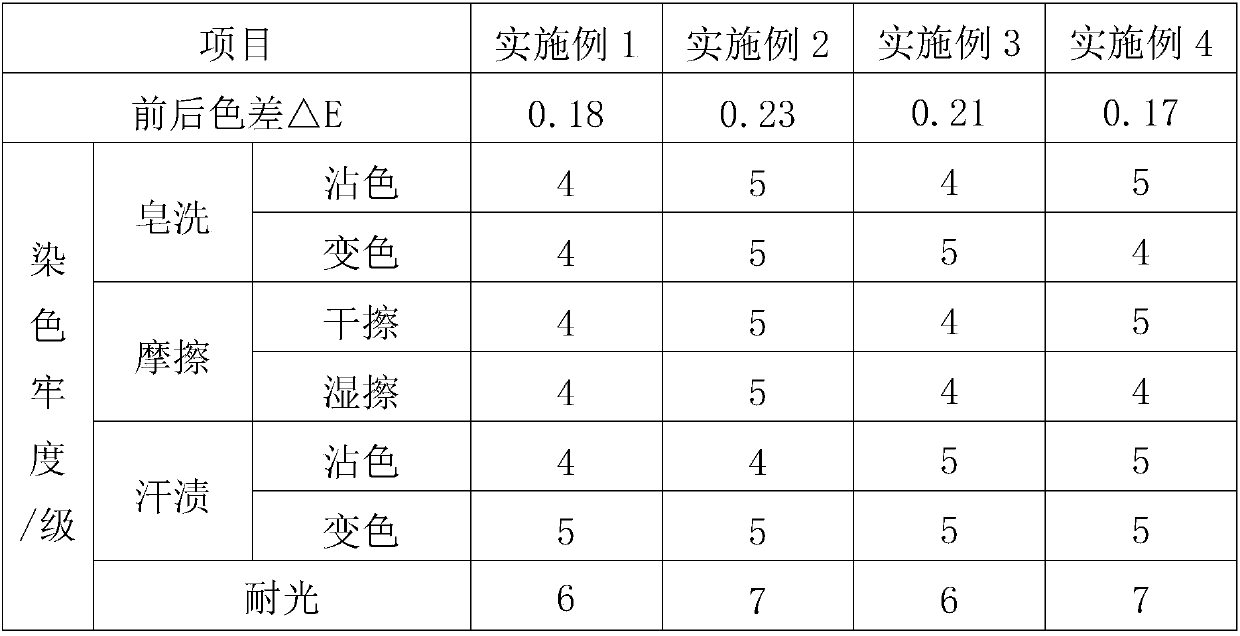

Examples

Embodiment 1

[0024] In this embodiment, a disperse bath dyeing process of polyester-cotton microcapsule disperse dyes comprises sequentially performing microcapsule disperse dye treatment processes and vat dye treatment processes;

[0025] Wherein, the microcapsule disperse dye treatment process includes microcapsule disperse dye dyeing, initial washing, soaping and post-washing; the vat dye treatment process includes dye reduction, dyeing, washing, oxidation, soaping, hot washing and drying Dry;

[0026] In the microcapsule disperse dye dyeing process, the polyester-cotton blended fabric is dipped into the dye solution according to the bath ratio of 1:16, and the dye solution formula includes: microcapsule disperse dye 2% (owf), pH buffer 1.6g / L and leveling agent 1.2g / L, then dye at 24°C, raise the temperature to 62°C at a heating rate of 2.8°C / min, keep it for 12 minutes, and then raise the temperature to 100°C at a heating rate of 1.3°C / min, Keep warm for 30 minutes, then isolate the...

Embodiment 2

[0030] In this embodiment, a disperse bath dyeing process of polyester-cotton microcapsule disperse dyes comprises sequentially performing microcapsule disperse dye treatment processes and vat dye treatment processes;

[0031] Wherein, the microcapsule disperse dye treatment process includes microcapsule disperse dye dyeing, initial washing, soaping and post-washing; the vat dye treatment process includes dye reduction, dyeing, washing, oxidation, soaping, hot washing and drying Dry;

[0032] In the microcapsule disperse dyeing process:

[0033] The microcapsule disperse dye dyeing process comprises that the polyester-cotton blended fabric is dipped in a dye solution according to a bath ratio of 1:10, and the dye solution formula includes: microcapsule disperse dye 3% (owf), pH buffer 1g / L and level dyeing Dye at 20°C, raise the temperature to 55°C at a heating rate of 3°C / min, keep it for 15 minutes, then raise the temperature to 110°C at a heating rate of 1°C / min, keep it f...

Embodiment 3

[0040] In this embodiment, a disperse bath dyeing process of polyester-cotton microcapsule disperse dyes comprises sequentially performing microcapsule disperse dye treatment processes and vat dye treatment processes;

[0041] Wherein, the microcapsule disperse dye treatment process includes microcapsule disperse dye dyeing, initial washing, soaping and post-washing; the vat dye treatment process includes dye reduction, dyeing, washing, oxidation, soaping, hot washing and drying Dry;

[0042] In the microcapsule disperse dyeing process:

[0043] The microcapsule disperse dye dyeing process comprises that the polyester-cotton blended fabric is dipped in a dye solution according to a bath ratio of 1:20, and the dye solution formula includes: microcapsule disperse dye 1% (owf), pH buffer 2g / L and level dyeing Dyeing at 30°C, heating to 65°C at a heating rate of 2°C / min, holding for 8 minutes, then raising the temperature to 90°C at a heating rate of 1.5°C / min, holding for 35 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com