Preparation method for calcium carbonate whiskers extracted from limestone

A technology for calcium carbonate whiskers and limestone, which is applied in chemical instruments and methods, single crystal growth, crystal growth and other directions, can solve problems such as increasing the production cost of calcium carbonate whiskers, and achieve the effects of convenient regulation and low process cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The specific process and process parameters of calcium carbonate whisker preparation are:

[0035] (1) Crushing and grinding the raw limestone ore, passing through a 75 μm square hole sieve;

[0036] (2) Weigh the silane coupling agent KH550, limestone powder and distilled water respectively according to the mass ratio, wherein KH550: limestone powder: water = 0.015:1:100, and stir evenly until KH550 is completely dissolved to obtain a raw material suspension.

[0037] (3) Place the raw material suspension in a vacuum device, remove the air in the device through vacuum exhaust, quickly open the air valve, and introduce CO 2 Gas, raise the gas pressure to 0.1MPa and keep it constant.

[0038] (4) After reacting for 4 hours, draw the supernatant liquid into the flask, immerse the flask under the liquid level of the constant temperature water bath, set the temperature of the water bath to 80°C, and react for 3 hours under the condition of rapid stirring (speed 1000rpm). ...

Embodiment 2

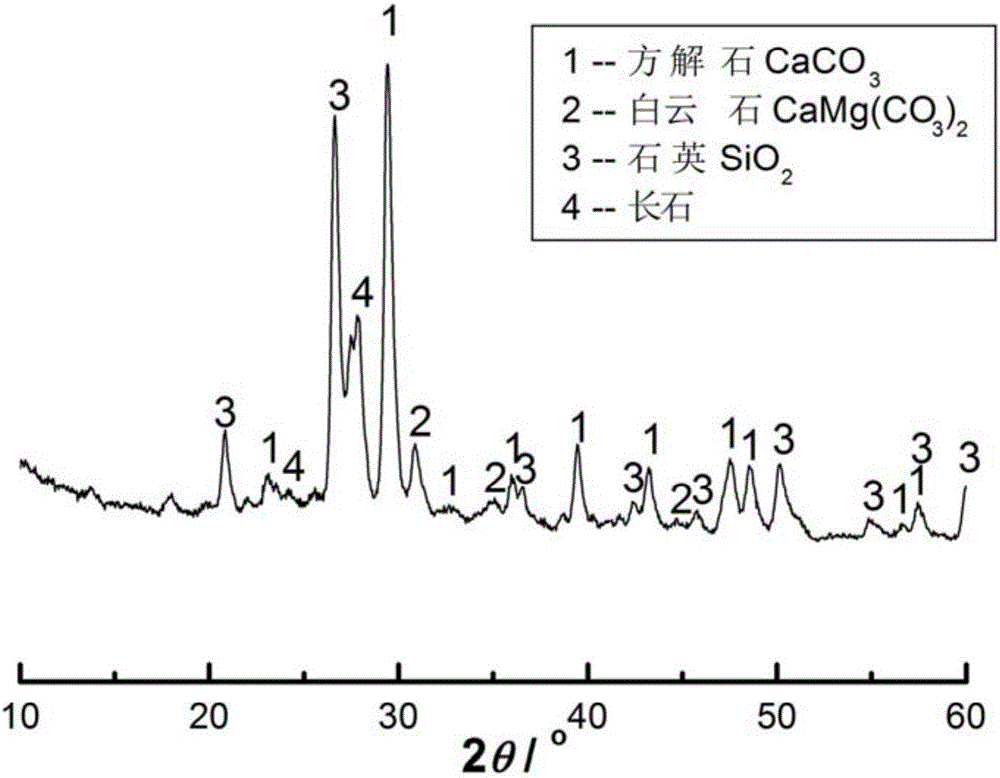

[0042] The calcium carbonate whiskers were obtained in the steps of Example 1, the difference being that the control temperature of step (4) constant temperature water bath was adjusted to 90°C, the reaction times 1h, stirring speed 10000rpm; other operating steps and conditions were the same. The SEM and XRD analysis of the obtained product showed that the morphology of the product did not change significantly, but the proportion of the aragonite phase decreased and the relative calcite phase increased.

Embodiment 3

[0044] The calcium carbonate whiskers were obtained in the steps of Example 1, the difference being that the control temperature of step (4) constant temperature water bath was adjusted to 60°C, the reaction times 2h, stirring speed 5000rpm; other operating steps and conditions were the same. The SEM and XRD analyzes of the obtained product show that the calcium carbonate whiskers of the product have a diameter of 2-10 μm and a length of 30-50 μm, that is, the size of the whiskers increases, and the purity of the calcium carbonate whiskers is 96.2 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com