Wood adhesive

A wood adhesive and stabilizer technology, applied in the directions of adhesive additives, adhesive types, starch-derived adhesives, etc. The effect of obvious advantages, simple equipment and strong water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

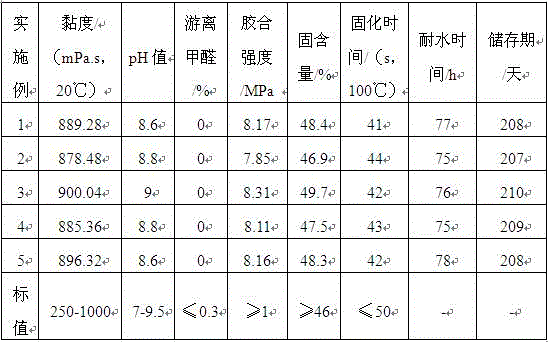

Examples

preparation example Construction

[0034] The preparation method of described wood adhesive comprises the following steps:

[0035] S1: prepare arrowroot starch slurry I with a concentration of 16-23Be' and a pH value of 3.2-3.9;

[0036] S2: Add fatty acid glycerides, N,N-dimethylformamide, coupling agent, catalyst with a concentration of 1%-1.9% to the arrowroot starch slurry I in step S1, and then at a temperature of 45-55°C, Carry out cross-linking and branching reaction at a stirring speed of 60-80r / min for 3-4h to prepare slurry II;

[0037] S3: Add sodium hydroxide to the slurry II of step S2, adjust the pH value to 9.2-9.6, then add epoxy chlorobutane, urea, initiator, plasticizer, toughening agent, tackifier, and then The temperature is 56-58°C, the stirring speed is 50-100r / min, and the crosslinking reaction is carried out for 1.5-2h to prepare the slurry III;

[0038] S4: Add a stabilizer to the slurry III in step S3, adjust the pH value to 7.8-8.2, raise the temperature to 75-79°C, gelatinize for ...

Embodiment 1

[0041] A wood adhesive, in parts by weight, comprising the following raw materials: 132 parts of arrowroot starch, 15 parts of fatty acid glycerides, 13 parts of N, N-dimethylformamide, 4 parts of sodium hydroxide, epoxy chloride 5 parts of butane, 4 parts of urea, 0.5 parts of coupling agent, 0.3 parts of initiator, 0.2 parts of catalyst, 0.3 parts of stabilizer, 0.8 parts of defoamer, 0.9 parts of plasticizer, 0.8 parts of toughening agent, tackifier 0.6 copies;

[0042] The coupling agent is 2,5-dimethyl-2,5-bis(benzoylperoxy)-hexane;

[0043] The initiator is azobisisobutyrate (ethylene glycol acrylate);

[0044] The catalyst is a platinum catalyst;

[0045] The stabilizer is an organotin stabilizer;

[0046] Described defoamer is polyoxyethylene polyoxypropylene pentaerythritol ether;

[0047] Described plasticizer is citric acid ester;

[0048] Described toughening agent is polypropylene adiene rubber;

[0049] Described tackifier is propyltrimethoxysilane;

[005...

Embodiment 2

[0056] A wood adhesive, in parts by weight, comprising the following raw materials: 104 parts of arrowroot starch, 13 parts of fatty acid glycerides, 11 parts of N, N-dimethylformamide, 2 parts of sodium hydroxide, epoxy chloride 3 parts of butane, 2 parts of urea, 0.3 part of coupling agent, 0.1 part of initiator, 0.1 part of catalyst, 0.1 part of stabilizer, 0.5 part of defoamer, 0.6 part of plasticizer, 0.5 part of toughening agent, tackifier 0.4 copies;

[0057] The coupling agent is 2,5-dimethyl-2,5-bis(benzoylperoxy)-hexane;

[0058] The initiator is azobisisobutyrate (ethylene glycol acrylate);

[0059] The catalyst is a platinum catalyst;

[0060] The stabilizer is an organotin stabilizer;

[0061] Described defoamer is polyoxyethylene polyoxypropylene pentaerythritol ether;

[0062] Described plasticizer is citric acid ester;

[0063] Described toughening agent is polypropylene adiene rubber;

[0064] Described tackifier is propyltrimethoxysilane;

[0065] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com