Gas cabinet anti-corrosion paint and preparation method thereof

An anti-corrosion paint and gas tank technology, applied in the field of coatings, can solve the problems of difficult oil level control, inability to ensure the safe operation of the gas tank with the sealing effect of the sealing oil, and accelerating the emulsification of the sealing oil, so as to improve the water resistance, improve the long-term anti-corrosion effect, The effect of enhancing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

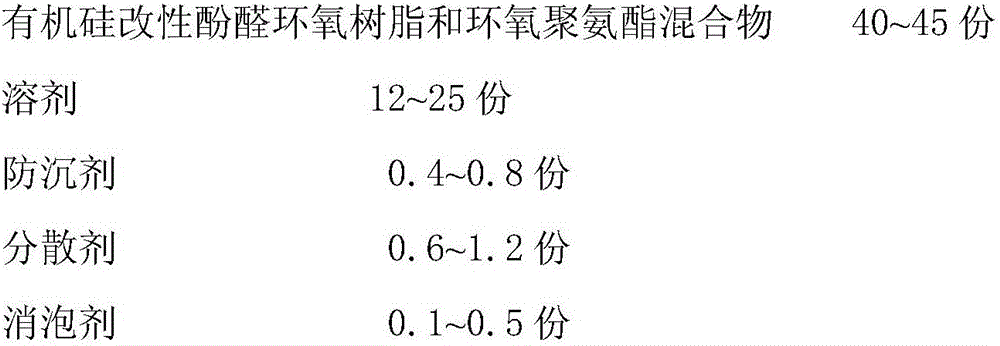

[0028] (1) Mix 40 parts of silicone-modified novolac epoxy resin and epoxy polyurethane in a mass ratio of 1:0.8 to form 2 / 3 of the mixture and 12 parts of xylene, 0.4 parts of polyurea grafted hydroxyl acrylic resin, Add 0.6 parts of dispersant to the container and stir at high speed for 10 minutes, then add 0.1 parts of defoamer and 0.2 parts of leveling agent, and then stir evenly at low speed; finally add 5.2 parts of rutile titanium dioxide, 0.5 parts of coloring pigment, and 4 parts of flake extender pigment , 2.8 parts of anti-rust agent, 13 parts of extender and stir evenly to obtain a mixture;

[0029] (3) Pump the mixture in step (2) into a grinder at 600r / min to grind to a fineness of ≤35μm; then add the remaining silicone-modified novolac epoxy resin and epoxy polyurethane mixture, and continue stirring for 15min Get A component;

[0030] (4) Mix 4 parts of epoxy polyamide curing agent and 4 parts of xylene to obtain B component;

[0031] (5) Mix component A and ...

Embodiment 2

[0035] (1) Mix 45 parts of silicone-modified novolac epoxy resin and epoxy polyurethane in a mass ratio of 1:1.5, 2 / 3 of the mixture, 25 parts of isopropanol, and 0.8 parts of polyurea grafted hydroxyl acrylic resin 1.2 parts of dispersant were added to the container and stirred at high speed for 20 minutes, then 0.5 parts of defoamer and 0.5 parts of leveling agent were added, and then stirred evenly at low speed; finally, 10 parts of rutile titanium dioxide, 1.2 parts of coloring pigment and 8 parts of flake extender were added part, 5.0 parts of antirust agent, 23 parts of bulking agent and stir to obtain mixture;

[0036] (3) Pump the mixture in step (2) into a grinder at 1000r / min to grind to a fineness of ≤35μm; then add the remaining silicone-modified novolac epoxy resin and epoxy polyurethane mixture, and continue stirring for 30min Get A component;

[0037] (4) Mix 8 parts of epoxy polyamide curing agent and 4 parts of isopropanol evenly to obtain component B;

[00...

Embodiment 3

[0040] (1) Mix 42 parts of silicone-modified novolac epoxy resin and epoxy polyurethane in a mass ratio of 1:1, 2 / 3 and 20 parts of butanol in the mixture, 0.5 parts of polyurea grafted hydroxyl acrylic resin, Add 1 part of dispersant to the container and stir at high speed for 15 minutes, then add 0.3 parts of defoamer and 0.3 parts of leveling agent, and then stir evenly at low speed; finally add 8 parts of rutile titanium dioxide, 1 part of coloring pigment, and 5 parts of flaky extender pigment , 3 parts of anti-rust agent, 20 parts of extender and stir evenly to obtain a mixture;

[0041] (3) Pump the mixture in step (2) into a grinder at 800r / min to grind to a fineness of ≤35μm; then add the remaining silicone-modified novolak epoxy resin and epoxy polyurethane mixture, and continue stirring for 20min Get A component;

[0042] (4) Mix 5 parts of epoxy polyamide curing agent and 3 parts of butanol evenly to obtain component B;

[0043] (5) Mix component A and component ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com