Method for preparing amorphous tildipirosin

A new, amorphous technology of tedrol, which is applied in the field of preparation of tedrol, can solve problems such as difficulty, poor control, and high cost of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add 5g of Tideroloxine raw material into 70g of isopropyl ether, stir and dissolve at 65°C, filter to obtain a clear solution, add 15mL of water dropwise, stir for 2h to obtain a white solid, and filter with suction to obtain a wet sample.

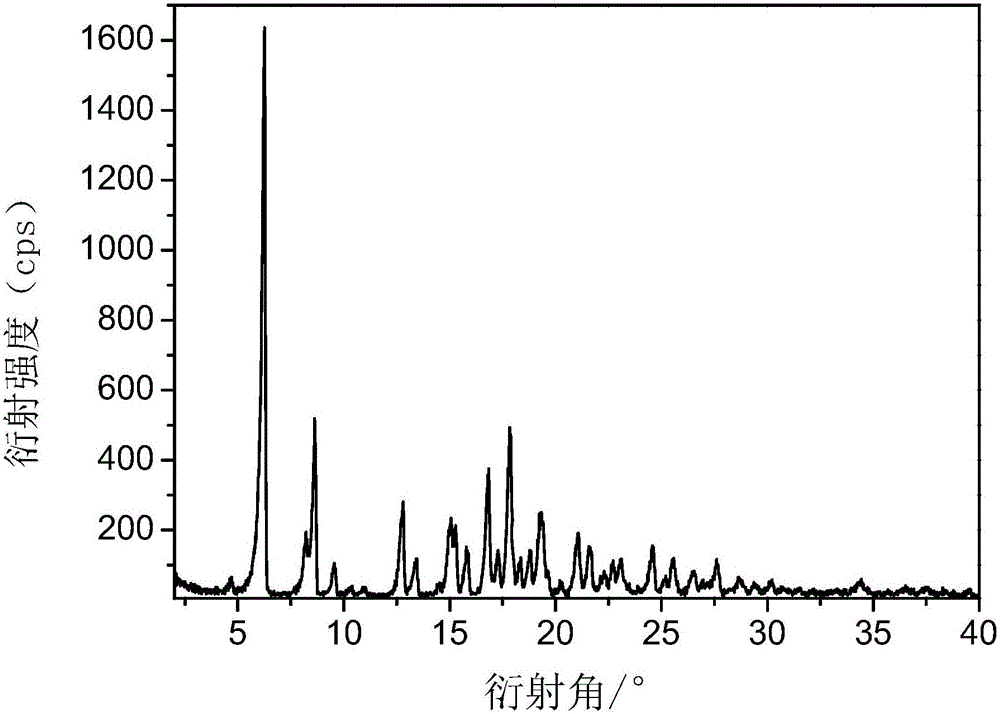

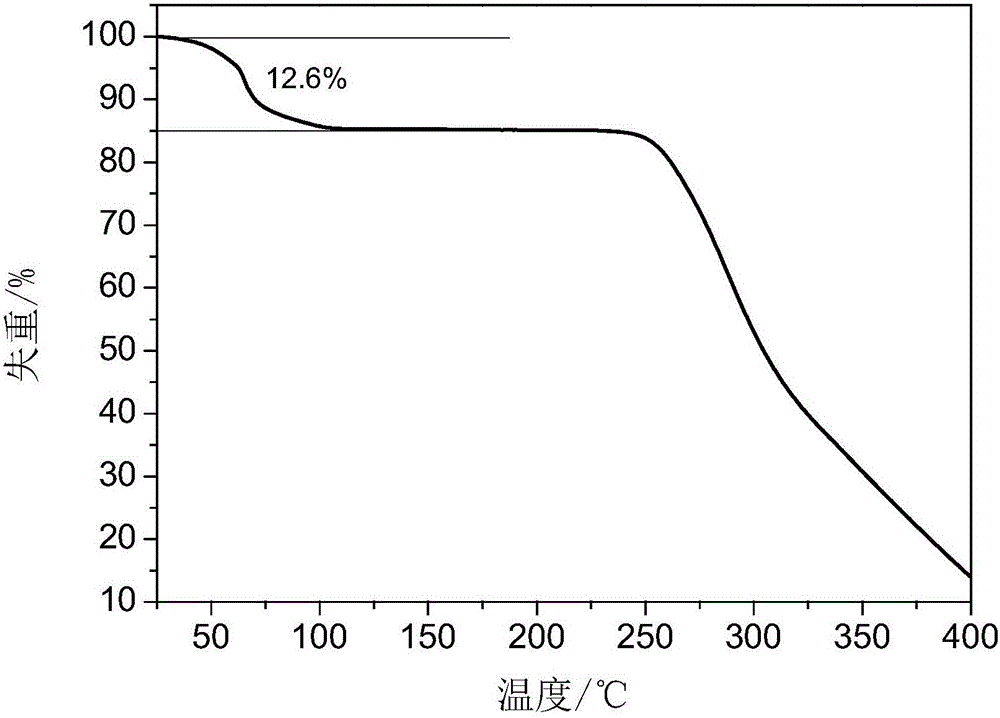

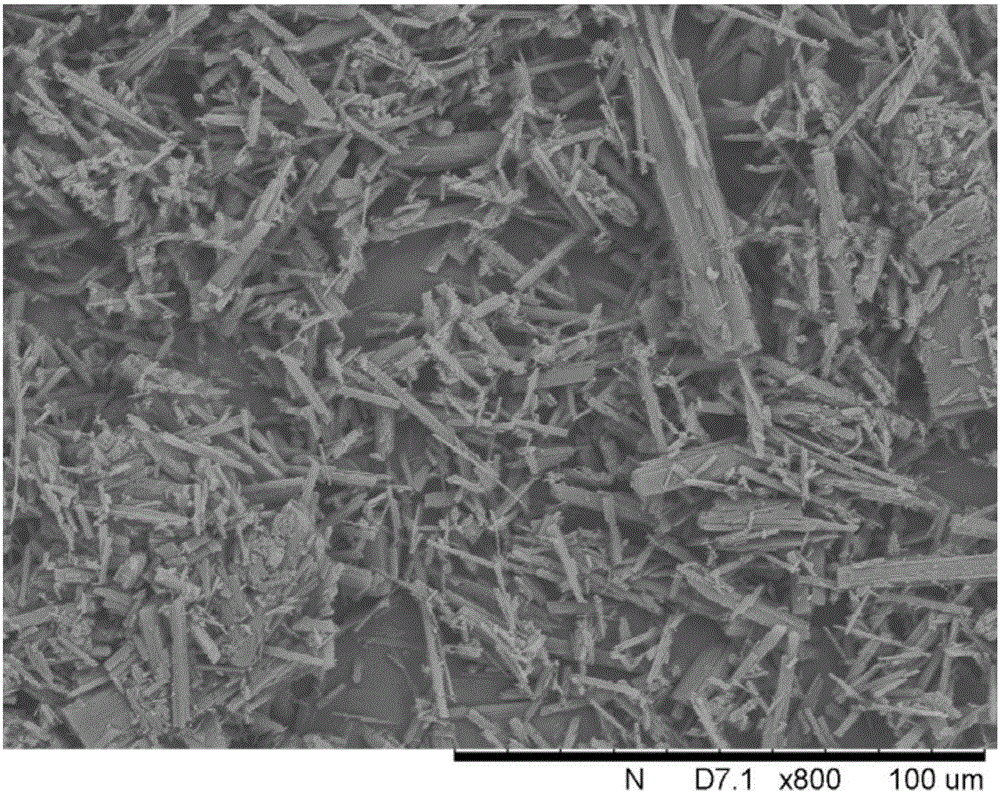

[0037] Do the XRD analysis spectrum of the wet sample as attached figure 1 As shown, there are obvious diffraction peaks at 2θ=4.70±0.2, 6.26±0.2, 8.22±0.2, 8.64±0.2, 9.56±0.2, 10.39±0.2, 10.97±0.2, 12.80±0.2, 13.42±0.2, 14.44±0.2 0.2, 15.06±0.2, 15.28±0.2, 15.78±0.2, 16.84±0.2, 17.28±0.2, 17.84±0.2, 18.35±0.2, 18.78±0.2, 19.34±0.2, 20.30±0.2, 21.08±0.2, 21.58±0.2 have characteristic peaks. The thermogravimetric weight loss map of the wet sample is attached figure 2 As shown, there is 12.6% weight loss before 100°C; the scanning electron microscope photos of wet samples are attached image 3 As shown, it is a long rod crystal form, indicating that the wet sample is an isopropyl ether solvent compound.

[0038] Place the wet sam...

Embodiment 2

[0040] Add 4 g of Tideroloxine raw materials to 60 g of isopropyl ether, stir and dissolve at a constant temperature of 50 ° C, filter to obtain a clear solution, add 10 mL of water dropwise and continue stirring for 1 h to obtain a white solid, and suction filter to obtain a wet sample. Wet sample is made XRD analysis pattern and attached figure 1 Consistent, with the same peak spectrum position and shape; thermogravimetric analysis weight loss is 12.5%. The wet sample was placed in a vacuum drying oven at 80°C and dried under normal pressure for 3 hours to obtain 3.68 g of an amorphous solid product of Tedirosin. The XRD pattern of the sample and the attached Figure 4 Same, no obvious peak shape, no weight loss by thermogravimetric analysis.

Embodiment 3

[0042] Add 2g of Tideroloxine raw material to 60g of isopropyl ether, stir to dissolve at 40°C, filter to obtain a clear solution, add 20mL of water dropwise, and continue stirring for 1h to obtain a white solid, which is obtained by suction filtration to obtain a wet sample. Wet sample is made XRD analysis pattern and attached figure 1 Consistent, with the same peak spectrum position and shape; thermogravimetric analysis weight loss is 12.3%. The wet sample was placed in a vacuum drying oven at 60°C for 3 hours to obtain 1.69 g of an amorphous solid product of Tedirosin. The XRD pattern of the sample and the attached Figure 4 Same, no obvious peak shape, no weight loss by thermogravimetric analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com