Imidazolium perrhenate ionic liquid with amino groups as well as preparation method and application of imidazolium perrhenate ionic liquid

A technology of ionic liquid and perrhenate, applied in chemical instruments and methods, catalytic reactions, organic chemistry, etc., to achieve high yield, simple process, and guaranteed catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 has the imidazolium perrhenate ionic liquid of monoamino

[0025] The structural formula of the imidazolium perrhenate ionic liquid with a single amino group is as follows:

[0026]

[0027] where R=CH 3 , C 4 h 9 , CH 2 =CH; n=2,3.

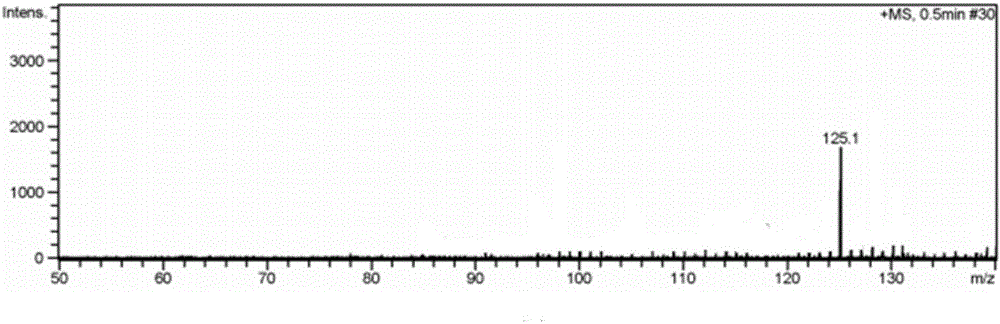

[0028] (1) 1-aminopropyl-3-butylimidazolium perrhenate ([NH 2 pbim][ReO 4 ]) preparation

[0029] 1) Under the protection of nitrogen, mix 3-bromopropylamine hydrobromide and n-butylimidazole at a molar ratio of 1:1.1, dissolve in a certain amount of absolute ethanol solution, reflux at 90°C for 24 hours, and depressurize After distilling off the ethanol solvent, add dichloromethane solvent, stir, filter, distill the filtrate under reduced pressure to remove dichloromethane, add an appropriate amount of KOH aqueous solution to make the pH of the solution 8-9 after vacuum drying, filter, and add absolute ethanol to the solid Solvent, stirred and dissolved, filtered, and the filtrate was vacuum-dried to obtain pure 1-...

Embodiment 2

[0040] Embodiment 2 has the imidazolium perrhenate ionic liquid of diamino

[0041] The structural formula of the imidazolium perrhenate ionic liquid with two amino groups is as follows:

[0042]

[0043] R=(CH 2 ) nNH 2 ;n=2,3

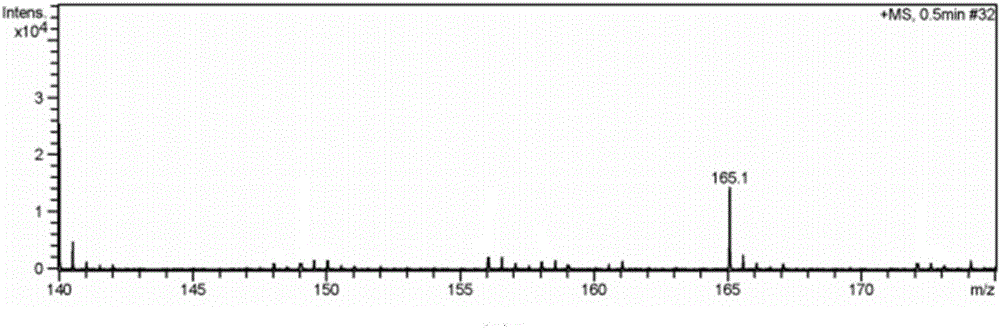

[0044] (1) 1,3-diaminopropylimidazole perrhenate ([2NH 2 pim][ReO 4 ]) Preparation:

[0045] 1) Under the protection of nitrogen, mix 3-bromopropylamine hydrobromide and trimethylsilyl imidazole at a molar ratio of 1:2.2, dissolve in a certain amount of absolute ethanol solution, and reflux at 90°C for 24 hours. The reaction solution gradually changed from clarification to light yellow transparent viscous liquid. After the ethanol solvent was removed by distillation under reduced pressure, the toluene solvent was added, stirred, filtered, and the filtrate was removed by distillation under reduced pressure. 9, filter, add dehydrated ethanol solvent in the solid, stir to dissolve, filter, after the filtrate is vacuum-dried, obtain target produc...

Embodiment 3

[0050] Example 3 Catalyzed Cycloaddition Reaction of Epoxy Compounds by Imidazolium Perrhenate Ionic Liquids with Amino Groups

[0051] (1) Temperature, CO 2 Effects of pressure, catalyst dosage and reaction time on reaction yield

[0052] The method is as follows: In a 50ml autoclave, add the catalyst [NH 2 pbim][ReO 4 ] and epichlorohydrin, mix, pass into CO 2 , react under the conditions shown in Table 1, the consumption of catalyst is 0.3%-1.0% of the epoxy compound moles. Calculate the productive rate of cyclic carbonate after the reaction finishes, and the results are shown in Table 1.

[0053] Table 1

[0054] Entry

[0055] In summary, the cycloaddition reaction of epoxy compounds catalyzed by imidazolium perrhenate ionic liquids with amino groups is preferably: in a 50ml autoclave, add catalyst and epoxy compounds, mix, pass into 5MP CO 2 , 160°C, reacted for 12 hours. The addition amount of catalyst is 1.0% of the mole number of epichlorohydrin. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com