Concrete-specific polycarboxylate water reducer for mixing basalt powder in concrete and preparation method thereof

A technology for concrete and polycarboxylic acid, which is applied in the field of preparation of special polycarboxylate water-reducing agent for concrete, concrete admixture, and polycarboxylate water-reducing agent for concrete, can solve problems such as no guidance scheme, and achieve adaptability Good, high water reduction rate, small loss over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

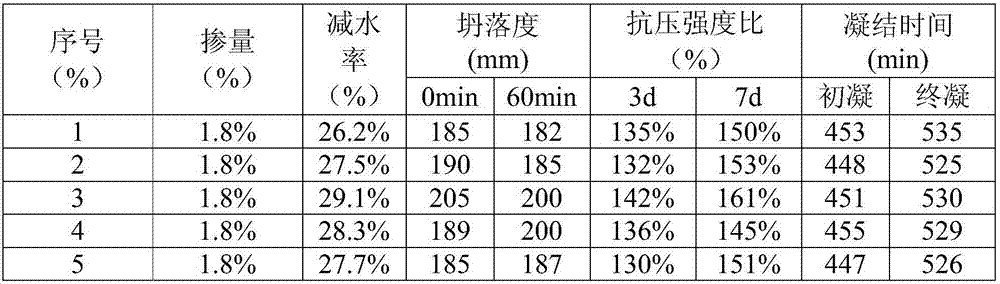

Examples

Embodiment 1

[0017] Embodiment 1: (for mixing basalt powder in concrete) special polycarboxylate water reducer for concrete of the present invention is made from the raw materials of following components and weight percent: (solid content is 40wt.%) Polycarboxylate superplasticizer mother liquor 20%, slow-release high-efficiency superplasticizer 2%, water retention agent 0.1%, retarder (sugar, can be sucrose) 2%, alcohol amines (triethanolamine) 1%, anti-corrosion Agent 0.02%, deionized water is the balance; the sum of the weight percentages of the above-mentioned components is 100%. The water-retaining agent is hydroxypropyl methylcellulose, and the preservative is potassium sorbate.

[0018] The preparation method of the concrete polycarboxylate water reducer (for mixing basalt powder in concrete) comprises the following process steps: first add 75% deionized water in the mixing tank (the addition of deionized water is 75% of its total weight), then add (retarder) sugar, stir for 15 min...

Embodiment 2

[0019] Embodiment 2: (for mixing basalt powder in concrete) special polycarboxylate water reducer for concrete of the present invention is made from the raw materials of following components and weight percent: (solid content is 40wt.%) Polycarboxylate superplasticizer mother liquor 25%, slow-release high-efficiency superplasticizer 2.5%, water retention agent 0.1%, retarder (citric acid monohydrate) 2.5%, alcohol amines (triethanolamine) 1%, preservative 0.01%, and deionized water is the balance; the sum of the weight percentages of the above-mentioned components is 100%. The water-retaining agent is methyl cellulose, and the preservative is potassium sorbate.

[0020] The preparation method of the concrete-specific polycarboxylate water reducer (for mixing basalt powder in concrete) comprises the following process steps: first add 69% deionized water in the mixing tank (the addition of deionized water is 69% of its total weight), then add (retarder) citric acid monohydrate,...

Embodiment 3

[0021] Embodiment 3: (for mixing basalt powder in concrete) special polycarboxylate water reducer for concrete of the present invention is made from the raw materials of following components and weight percent: (solid content is 40wt.%) Polycarboxylate superplasticizer mother liquor 30%, slow-release high-efficiency superplasticizer 1.5%, water retention agent 0.1%, retarder 2%, alcohol amines (triisopropanolamine) 2%, preservative 0.03%, Deionized water is the balance; the weight percentage sum of the above-mentioned components is 100%. The retarder is a combination of HEDP and sodium gluconate, and the weight ratio of HEDP and sodium gluconate is 1:1. The water-retaining agent is a combination of hydroxypropylmethylcellulose and methylcellulose, the weight ratio of hydroxypropylmethylcellulose and methylcellulose is 1:2, and the preservative is sorbic acid The combination of potassium and sodium acetate, the weight ratio of potassium sorbate and sodium acetate is 1:0.5.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com