Method for producing mineral wool by using early-stage molten-state steel slag of converter

A molten state, converter technology, used in glass manufacturing equipment, manufacturing tools, etc., can solve the problem of inability to solve the problem of steel slag recycling, unsuitable steel slag, and no metal resource recovery, so as to maintain a virtuous cycle, reduce production costs, Achieving the effect of high value-added utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] In this embodiment "a method of producing mineral wool by using molten steel slag in the early stage of converter", the raw material composition mass percentage is: 80% molten steel slag in the early stage of converter, 15% reducing agent, and 5% modifying agent. The molten steel slag in the early stage of the converter includes the following components in mass percentage: CaO 37%, SiO 2 29%, FeO 25%, MgO 4%, Al 2 o 3 3%. The reducing agent is a mixture of ferrosilicon and aluminum particles with a particle size of 10-30mm. The modifying agent is broken glass with a particle size of 5-20 mm.

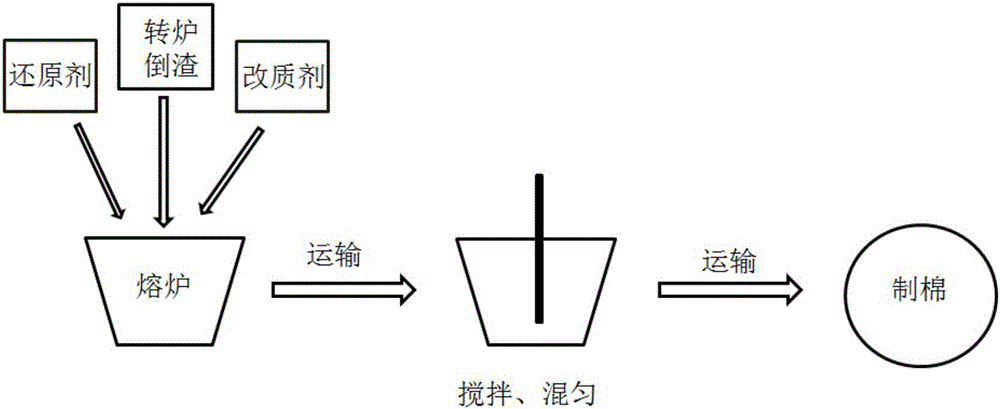

[0053] combine figure 1 , the steps of present embodiment producing mineral wool are:

[0054] (1) At a temperature of about 1400°C, pour the slag of the converter double slag retention method with a slag basicity of 1.3 into the melting furnace. Each converter is equipped with 3 melting furnaces, and a reducing agent is added during the process of placing the steel slag in...

Embodiment 2

[0059] In this embodiment "a method of producing mineral wool by using molten steel slag in the early stage of the converter", the raw material composition mass percentage is: 80% molten steel slag in the early stage of the converter, 10% reducing agent, 10% modifier, and molten steel slag in the early stage of the converter. Steel slag includes the following components in mass percentage: CaO 45%, SiO 2 25%, FeO 20%, MgO 5%, Al 2 o 3 2.5%. The reducing agent is ferrosilicon, with a particle size of 10-30mm. The modifying agent is clay with a particle size of 5-20mm.

[0060] combine figure 1 , the steps of present embodiment producing mineral wool are:

[0061] (1) At a temperature of about 1420°C, pour the slag of the converter double slag retention method with a slag basicity of 1.8 into the melting furnace. Each converter is equipped with 4 melting furnaces. The melting furnace is an improved slag tank, and the shell is Steel plate, the inner wall is refractory ins...

Embodiment 3

[0066] In this embodiment "a method of producing mineral wool by using molten steel slag in the early stage of the converter", the raw material composition mass percentage is: 85% molten steel slag in the early stage of the converter, 9% reducing agent, and 6% modifier, and the molten steel slag in the early stage of the converter is Steel slag includes the following components in mass percentage: CaO 41%, SiO 2 29%, FeO 18%, MgO 6%, Al 2 o 3 3%. The reducing agent is aluminum particles with a particle size of 10-30mm. The modifier is fly ash with a particle size of 5-20mm.

[0067] combine figure 1 , the steps of present embodiment producing mineral wool are:

[0068] (1) At a temperature of about 1450°C, pour the slag of the converter double slag retention method with a slag basicity of 1.4 into the melting furnace. Each converter is equipped with 5 melting furnaces, and a reducing agent is added during the process of placing the steel slag in the melting furnace Red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com