Antibacterial flame-retardant nonwoven composite and preparation method thereof

A technology of composite materials and non-woven fabrics, applied in the direction of melt spinning, chemical instruments and methods, non-woven fabrics, etc., can solve the problems of single function, etc., and achieve the effects of short process flow, ductility, not easy to break, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

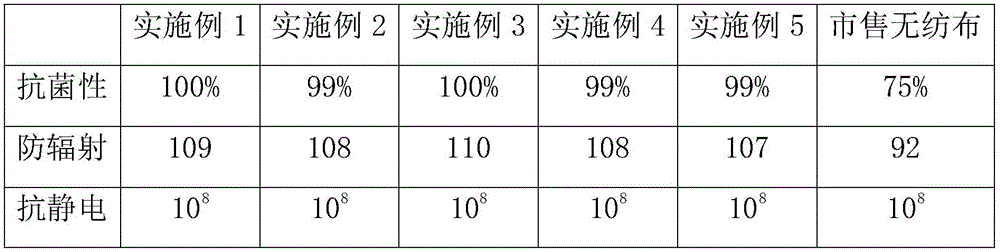

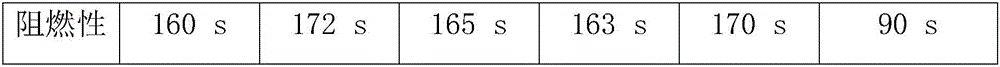

Examples

Embodiment 1

[0023] A medical antibacterial and flame-retardant non-woven composite material, the non-woven composite material sequentially includes from top to bottom: a first non-woven layer, a matrix layer and a second non-woven layer; the first non-woven A first antibacterial layer and a radiation-proof layer are sequentially arranged between the cloth layer and the matrix layer, and a second antibacterial layer and a flame-retardant antistatic layer are sequentially arranged between the second non-woven fabric layer and the matrix layer; The antibacterial layer is a porous nano activated carbon silver-loaded antibacterial agent coating with a particle size of 30nm, and the second antibacterial layer is a biological polypeptide antibacterial agent ε-polylysine layer; the radiation protection layer is made of carbon fiber and silver-loaded The fibers are interlaced and laid, the carbon fiber diameter is 4 μm, and the silver-loaded fiber diameter is 3 μm;

[0024] Wherein, the preparatio...

Embodiment 2

[0029] A medical antibacterial and flame-retardant non-woven composite material, the non-woven composite material sequentially includes from top to bottom: a first non-woven layer, a matrix layer and a second non-woven layer; the first non-woven A first antibacterial layer and a radiation-proof layer are sequentially arranged between the cloth layer and the matrix layer, and a second antibacterial layer and a flame-retardant antistatic layer are sequentially arranged between the second non-woven fabric layer and the matrix layer; The antibacterial layer is a porous nano activated carbon silver-loaded antibacterial agent coating with a particle size of 35nm, and the second antibacterial layer is a biological polypeptide antibacterial agent protamine sulfate layer; the radiation protection layer is made of carbon fibers and silver-loaded fibers. Formed by interlaced laying, the carbon fiber diameter is 3 μm, and the silver-loaded fiber diameter is 2 μm;

[0030] Wherein, the pre...

Embodiment 3

[0035]A medical antibacterial and flame-retardant non-woven composite material, the non-woven composite material sequentially includes from top to bottom: a first non-woven layer, a matrix layer and a second non-woven layer; the first non-woven A first antibacterial layer and a radiation-proof layer are sequentially arranged between the cloth layer and the matrix layer, and a second antibacterial layer and a flame-retardant antistatic layer are sequentially arranged between the second non-woven fabric layer and the matrix layer; The antibacterial layer is a porous nano activated carbon silver-loaded antibacterial agent coating with a particle size of 40nm, and the second antibacterial layer is a biological polypeptide antibacterial agent acid polymyxin layer; the radiation protection layer is composed of carbon fiber and silver-loaded fiber It is formed by interlacing with each other, the diameter of the carbon fiber is 5 μm, and the diameter of the silver-loaded fiber is 3.5 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com