Splash-proof sink for 50-bundle tube production equipment line

A production equipment and anti-splash technology, applied in the field of optical cable production, can solve problems such as difficulty in controlling the aperture, surface damage of the bundle tube, time-consuming and labor-intensive problems, and achieve the effects of reducing water splash, product quality assurance, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

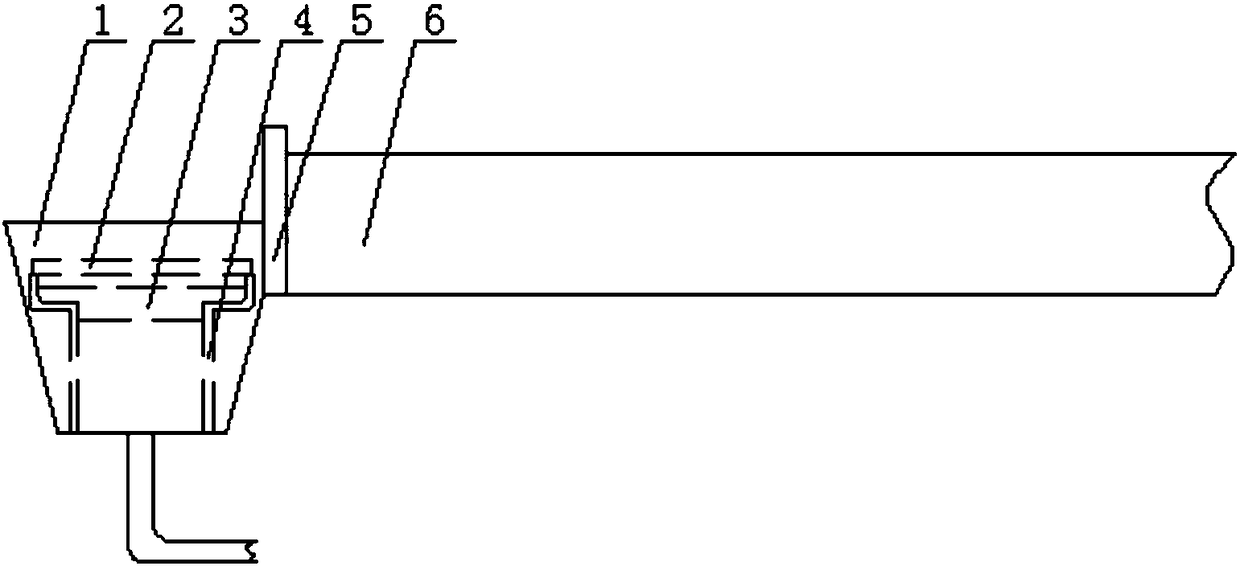

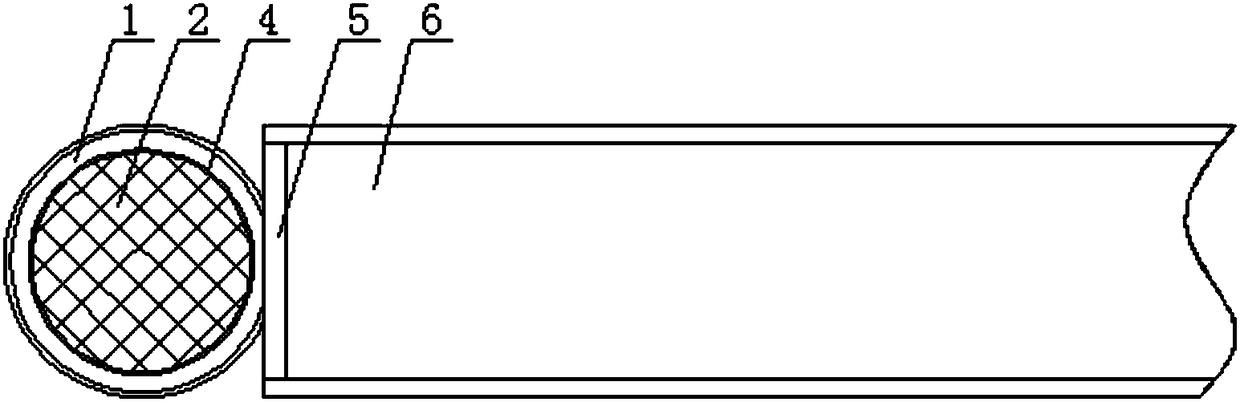

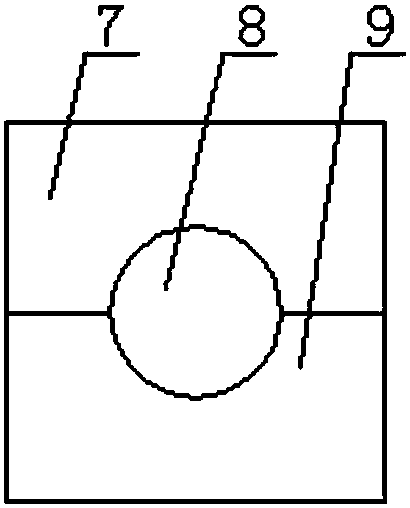

[0021] A splash-proof water tank for a 50-bundle tube production line, including a funnel 1, a baffle 5 and a tank body 6, the funnel is located below the outlet of the extruder bundle tubes, and the bottom of the funnel is connected to the outlet pipe. The rear end of the funnel is connected with the tank body, and a vertical baffle plate is arranged at the junction of the tank body and the funnel, and a through hole 8 for passing through the bundle tube is formed in the center of the baffle plate.

[0022] The innovation of the present invention is: a splash-proof device is installed in the funnel, the splash-proof device includes a bracket 4, a stainless steel mesh 2 and a soft sponge pad 3, the bracket is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com