Production technology for hard PVC high foaming plate

A production process and high-foaming technology, applied in flat products, household appliances, and other household appliances, can solve the problems of low hardness and low foaming ratio of PVC high-foaming boards, achieve high foaming ratios, and improve flame retardancy , high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

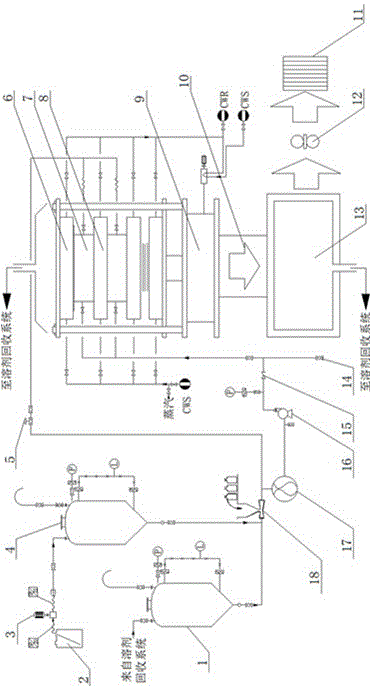

[0023] Refer to attached figure 1 , the present invention provides a kind of production technology of rigid PVC high-foaming board, comprising successively connected fresh solvent bucket 2, diaphragm pump 3, fresh solvent storage tank 4, feeding tank 18, kneader 17, feeding pump 16, foaming Machine 9, automatic conveyor 10, hot air circulation oven 13, cutting machine 12, solvent recovery tank 1 is also provided in front of feeding tank 18; foaming machine 9 has built-in heating plate Ⅰ6, mold 7, heating plate Ⅱ8, and the bottom of heating plate Ⅰ6 It is connected to the top of mold 7, the bottom of mold 7 is connected to the top of heating plate II8, the inlet of mold 7 is connected to the outlet of feed pump 16, the outlet of mold 7 is connected to kneader 17, heating plate I6 and heating plate II8 are equipped with steam heating and Circulating water cooling device, its operation steps are as follows:

[0024] Select PVC resin, calcium carbonate, talcum powder, aluminum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com