Mould release agent for rubber

A release agent, rubber technology, applied in the field of rubber release agent, can solve the problems of large amount of particles or powder used, allergens, rubber products and mold pollution, etc., and achieve a good release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

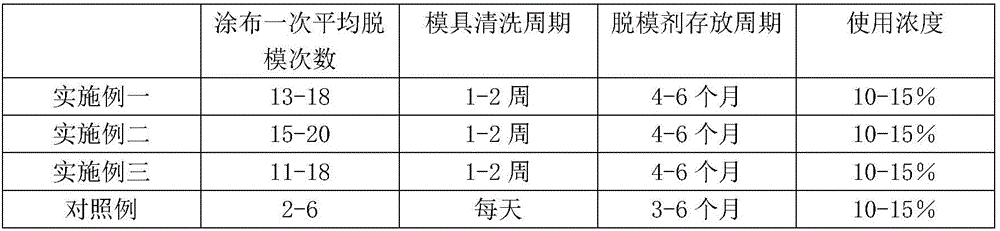

Examples

Embodiment 1

[0018] A kind of rubber release agent that the present invention proposes, comprises the raw material of following weight part: polytetrafluoroethylene 130 parts, methyl silicone oil 30 parts, polyacrylamide 25 parts, fatty alcohol 15 parts, polyethylene glycol ether 22 parts, 100 parts of fatty alcohol ether sodium sulfate, 18 parts of n-butyl phthalate, 20 parts of sodium xylene sulfonate, 30 parts of mica powder, 15 parts of toluene, 7 parts of isomeric alcohol polyoxyethylene ether, 170 parts of deionized water, 20 parts of joint agent, 7 parts of catalyst.

[0019] Its preparation method comprises the following steps:

[0020] S1. Weigh polytetrafluoroethylene, methyl silicone oil, polyacrylamide, fatty alcohol, polyethylene glycol ether, and toluene according to the proportions. Mix the above raw materials and put them in a blender, and keep stirring at a temperature of 45°C 35min;

[0021] S2, weigh fatty alcohol ether sodium sulfate, n-butyl phthalate, sodium xylene ...

Embodiment 2

[0024] A kind of rubber release agent that the present invention proposes, comprises the raw material of following weight part: polytetrafluoroethylene 180 parts, methyl silicone oil 40 parts, polyacrylamide 30 parts, fatty alcohol 20 parts, polyethylene glycol ether 30 parts, 120 parts of fatty alcohol ether sodium sulfate, 24 parts of n-butyl phthalate, 23 parts of sodium xylene sulfonate, 35 parts of mica powder, 18 parts of toluene, 11 parts of isomeric alcohol polyoxyethylene ether, 230 parts of deionized water, 22 parts of joint agent, 10 parts of catalyst.

[0025] Its preparation method comprises the following steps:

[0026] S1. Weigh polytetrafluoroethylene, methyl silicone oil, polyacrylamide, fatty alcohol, polyethylene glycol ether, and toluene according to the ratio of parts. Mix the above raw materials and put them into a mixer, and keep stirring at a temperature of 60°C 45min;

[0027] S2, weigh fatty alcohol ether sodium sulfate, n-butyl phthalate, sodium xy...

Embodiment 3

[0030] A kind of rubber release agent that the present invention proposes, comprises the raw material of following weight part: polytetrafluoroethylene 190 parts, methyl silicone oil 55 parts, polyacrylamide 38 parts, fatty alcohol 29 parts, polyethylene glycol ether 37 parts, 140 parts of fatty alcohol ether sodium sulfate, 35 parts of n-butyl phthalate, 27 parts of sodium xylene sulfonate, 48 parts of mica powder, 23 parts of toluene, 14 parts of isomeric alcohol polyoxyethylene ether, 280 parts of deionized water, 28 parts of joint agent, 13 parts of catalyst.

[0031] Its preparation method comprises the following steps:

[0032] S1. Weigh polytetrafluoroethylene, methyl silicone oil, polyacrylamide, fatty alcohol, polyethylene glycol ether, and toluene according to the ratio of parts. Mix the above raw materials and put them into a mixer, and keep stirring at a temperature of 75°C 55min;

[0033] S2, weigh fatty alcohol ether sodium sulfate, n-butyl phthalate, sodium xy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com