Preparation method of pressing type scandium containing dispenser cathode based on microwave sintering

A microwave sintering and diffusion cathode technology, which is applied in the manufacture of thermionic cathodes, thermionic cathodes, electron emission electrodes/cathodes, etc., can solve the problems of high material consumption and energy consumption in the sintering process, complex microfocus x-ray preparation process, and low dimensional accuracy. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

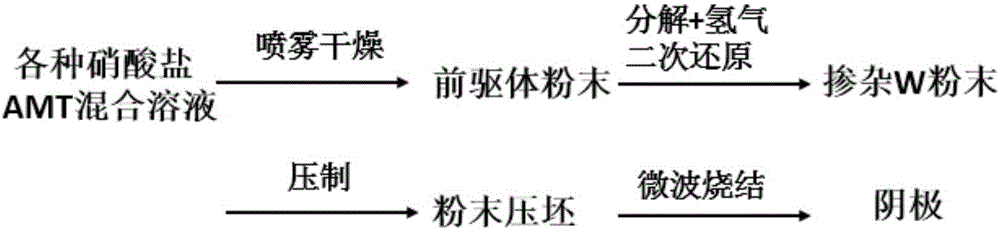

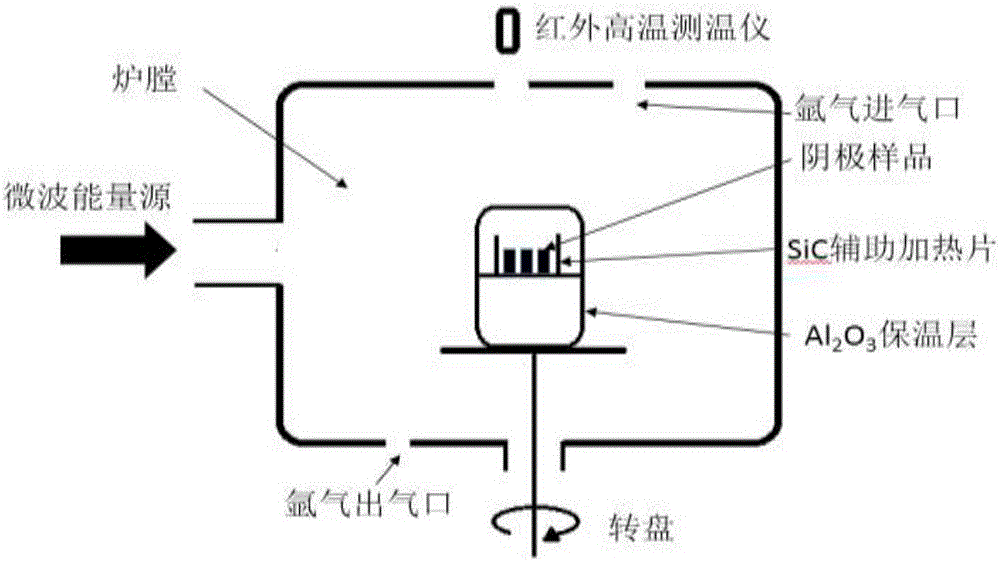

Method used

Image

Examples

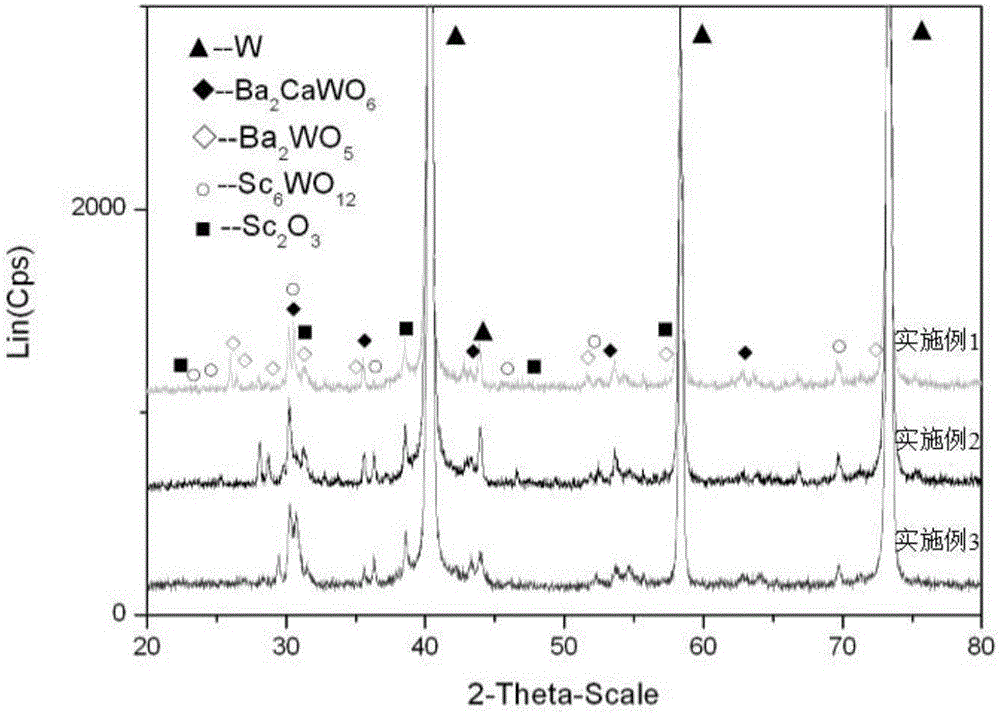

Embodiment 1

[0029] First, dissolve 20.34g of barium nitrate, 4.60g of calcium nitrate tetrahydrate, 14.61g of aluminum nitrate nonahydrate, 36.84g of scandium nitrate hexahydrate, and 160.668g of ammonium metatungstate in deionized water, and stir until they are all dissolved. Barium, calcium nitrate, and aluminum nitrate are prepared to make 411 salt solution, then mix scandium nitrate and ammonium metatungstate solution, and finally add 411 salt solution slowly, and at the same time stir continuously with a stirrer to make it fully mixed, the final total concentration 68.52g / L, the precursor powder was obtained by spray drying, the feed rate was 600ml / h, and the blast rate was 0.4m 3 / min-0.6m 3 / min, the inlet temperature is 150°C, and the outlet temperature is stable at 90-96°C; secondly, the obtained precursor powder is decomposed in a muffle furnace, and the powder is kept at 550°C in an atmospheric atmosphere (or oxygen atmosphere) for about 3 hours to remove The N element in the ...

Embodiment 2

[0031] First, dissolve 6.78g of barium nitrate, 1.53g of calcium nitrate tetrahydrate, 4.78g of aluminum nitrate nonahydrate, 12.28g of scandium nitrate hexahydrate, and 56.61g of ammonium metatungstate in deionized water, and stir until they are completely dissolved. Barium, calcium nitrate, and aluminum nitrate are prepared to make 411 salt solution, then mix scandium nitrate and ammonium metatungstate solution, and finally add 411 salt solution slowly, and at the same time stir continuously with a stirrer to make it fully mixed, the final total concentration 69.28g / L, the precursor powder was obtained by spray drying, the feed rate was 600ml / h, and the blast rate was 0.4m 3 / min-0.6m 3 / min, the inlet temperature is 150°C, and the outlet temperature is stable at 90-96°C; secondly, the obtained precursor powder is decomposed in a muffle furnace, and the powder is kept at 550°C in an atmospheric atmosphere (or oxygen atmosphere) for about 3 hours to remove The N element in t...

Embodiment 3

[0033]First, dissolve 20.34g of barium nitrate, 4.60g of calcium nitrate tetrahydrate, 14.61g of aluminum nitrate nonahydrate, 36.84g of scandium nitrate hexahydrate, and 160.668g of ammonium metatungstate in deionized water, and stir until they are all dissolved. Barium, calcium nitrate, and aluminum nitrate are prepared to make 411 salt solution, then mix scandium nitrate and ammonium metatungstate solution, and finally add 411 salt solution slowly, and at the same time stir continuously with a stirrer to make it fully mixed, the final total concentration 70.32g / L, the precursor powder was obtained by spray drying, the feed rate was 300ml / h, and the blast rate was 0.4m 3 / min-0.6m 3 / min, the inlet temperature is 150°C, and the outlet temperature is stable at 90-96°C; secondly, the obtained precursor powder is decomposed in a muffle furnace, and the powder is kept at 550°C in an atmospheric atmosphere (or oxygen atmosphere) for about 3 hours to remove The N element in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com