A magnetic modified boilestone material and its preparation methods and applications for adsorbing nickel removal

A modified zeolite and magnetic technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve problems such as the inability to effectively exert active hydroxyl adsorption performance, high reaction conditions, and poor hygiene and safety. Achieve the effect of saving precipitation time, easy to coalesce precipitation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

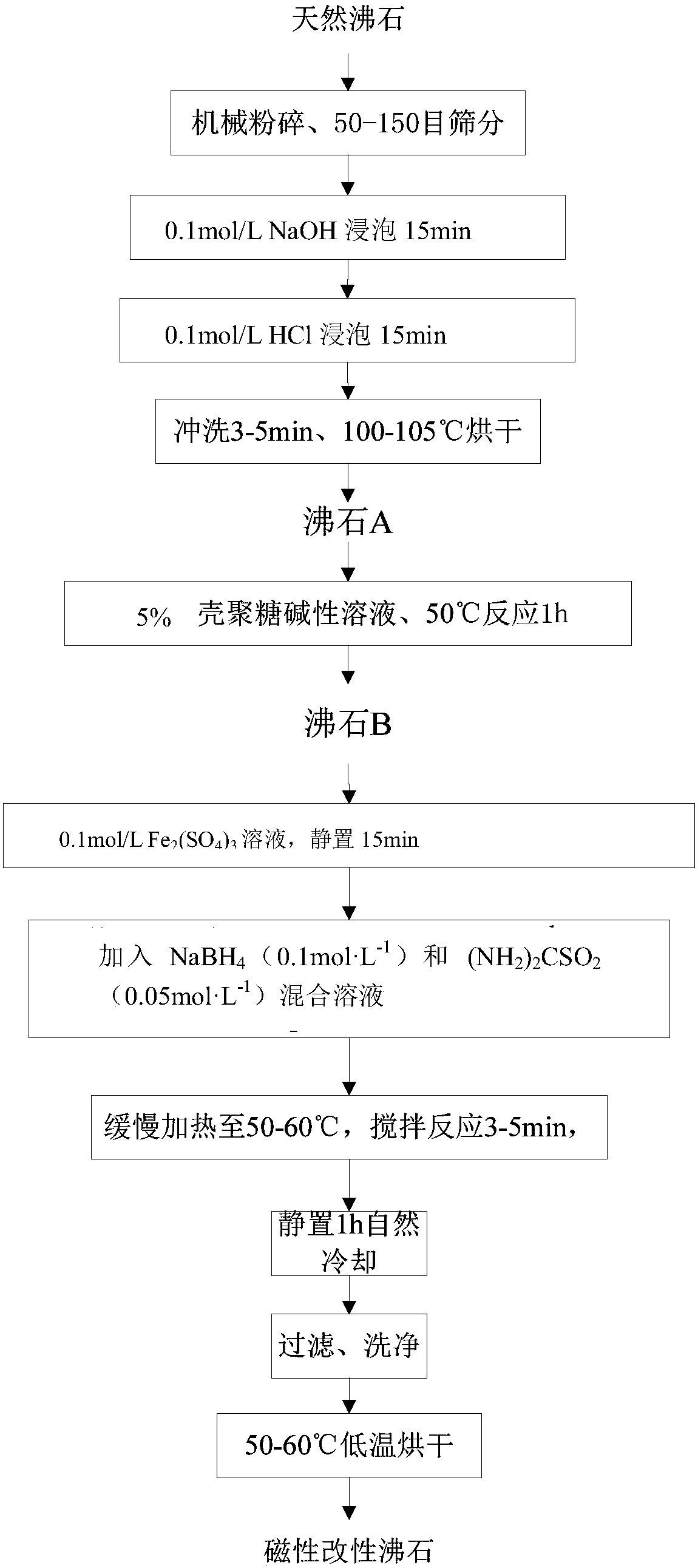

[0041] (1) The preparation of magnetically modified zeolite materials, the technological process is as follows figure 2 shown, including the following steps:

[0042] (1) Select natural clinoptilolite, mechanically pulverize, 100-150 mesh sieved, and wash with distilled water. -1 Soak in NaOH solution for 15min, then filter with polyester or vinylon filter cloth; then use 0.1mol·L -1 Soak in HCl solution for 15 minutes, filter again, wash with deionized water for 3-5 minutes, and dry at 100-105° C. to obtain zeolite A.

[0043] (2) React zeolite A in a chitosan alkaline solution with a mass concentration of 5% at 50° C. for 1 hour, then centrifuge and wash with distilled water to obtain zeolite B.

[0044] (3) Add zeolite B to 0.1mol L -1 Fe 2 (SO 4 ) 3 solution, let it stand for 15 minutes; under the condition of magnetic stirring, add the mixed alkaline solution at a volume ratio of 1:1; the NaBH in the mixed alkaline solution 4 The concentration is 0.1mol L -1 , (N...

Embodiment 2

[0055] (1) Preparation of magnetically modified zeolite material: the difference between this embodiment and Example 1 is that NaBH 4 and (NH 2 ) 2 CSO 2 In the mixed alkaline solution, the concentrations of the two are 0.05mol L -1 and 0.02mol·L -1 . Other steps and parameters are the same as in Example 1.

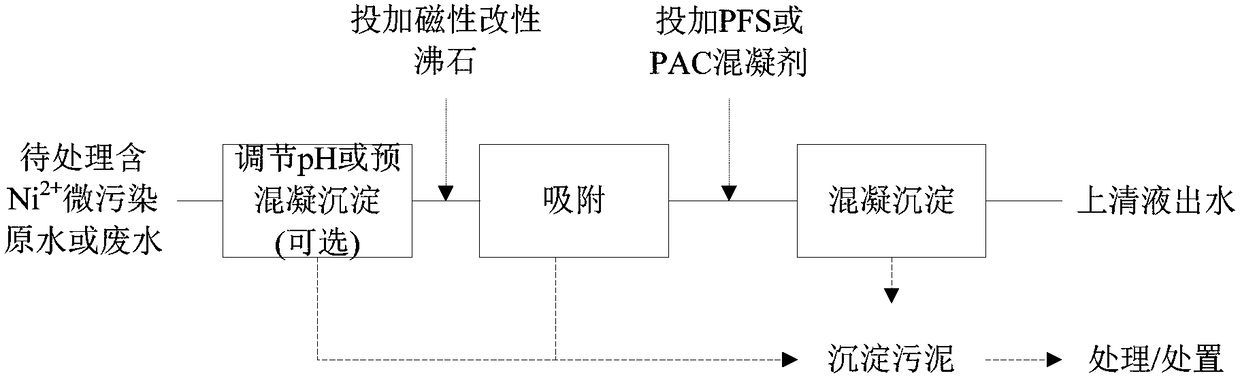

[0056] (2) Using the magnetically modified zeolite material prepared in step (1) to treat Ni in electroplating industrial wastewater2+ Exceeding the standard problem: after pretreatment in the workshop, Ni in the discharged wastewater 2+ Still as high as 2.0mg·L -1 , pH is 7-8.5, using such as image 3 The process shown is to add 2.0g·L first -1 The magnetically modified zeolite material, the adsorption time is 30min, and then add 1.5mg·L -1 After the PFS is coagulated and precipitated for 30 minutes, the effluent can be reduced to 0.3-0.4mg·L after filtration of quartz sand -1 , meeting emission standards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com