Waste gas absorption tower and waste gas absorption method

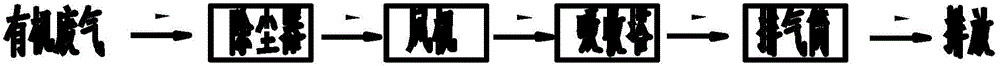

An absorption tower and waste gas technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of incomplete absorption of waste gas and easy occurrence of circulation, so as to ensure the gas-liquid contact time, improve the removal rate, and improve the waste gas. The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

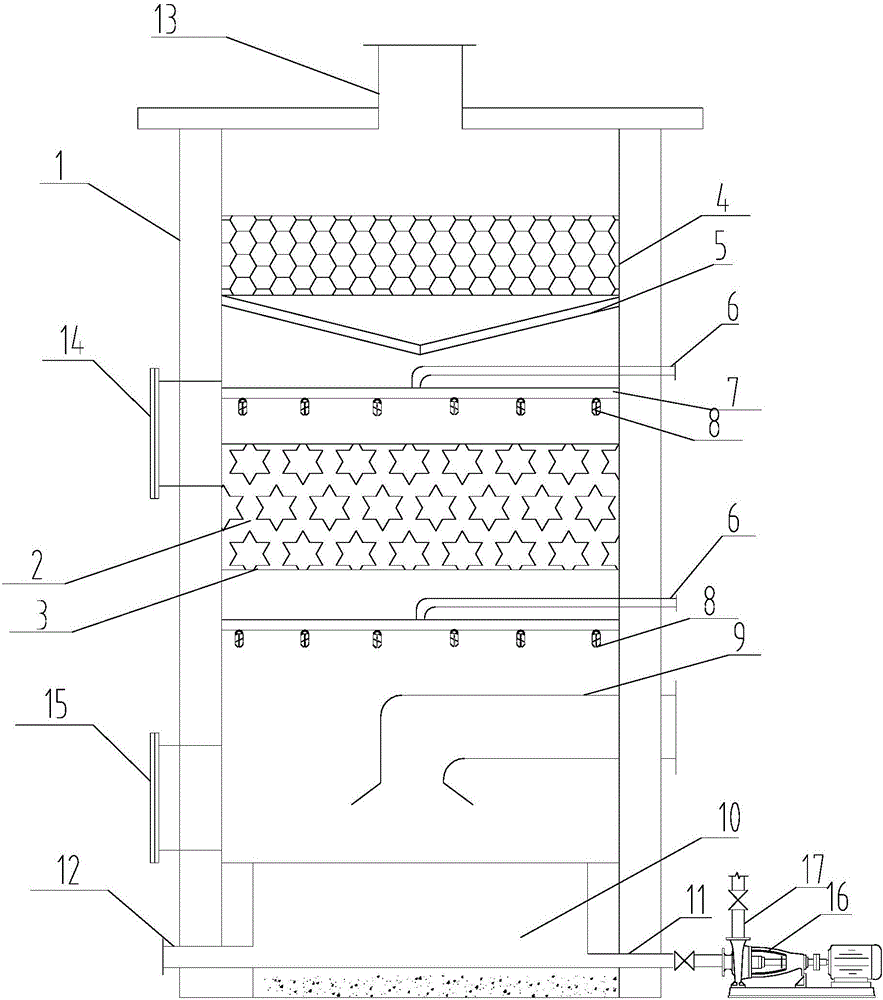

[0028] The structure diagram of the present invention is as figure 1 As shown, the exhaust gas absorption tower of the present invention includes an absorption tower tower body 1, a packing layer 2, a packing demister 4, a V-shaped tube type demister 5, an absorption liquid inlet pipe 6, a water distribution nozzle 8, an inlet Air pipe 9, circulating water pool 10, circulating pool outlet pipe 11, waste liquid discharge pipe 12, air outlet pipe 13, discharge port 14, inlet hole 15, absorption liquid circulating spray pump 16, water distribution nozzle 8 installed on the upper and lower layers The water distribution pipe 7, the water distribution pipe 7 is connected with the circulating liquid inlet pipe 6, the lower water distribution nozzle 8 is located near the entrance of the waste gas inlet pipe 9, the upper water distribution nozzle 8 is located near the top of the packing 2, and the liquid outlet pipe of the circulating pool 10 is connected to the circulating spray The s...

Embodiment 2

[0031] Like the waste gas absorption tower in Example 1, the tower body 1 can be square or other shapes with steel concrete as the main structure, which can be flexibly selected according to the site.

[0032] The working principle of the present invention is as follows: the exhaust gas enters the interior of the tower body 1 through the intake pipe 9 after dust removal, and the exhaust gas is first sprayed downward toward the circulating pool 10, and after being buffered, it is evenly upward, and is sprayed with the primary water distribution nozzle 8. The absorption liquid is in reverse contact. After the primary pretreatment, the waste gas enters the packing 2 through the stainless steel grid 3. At the same time, the secondary water distribution nozzle 8 continuously sprays the liquid to the packing 2. In the packing 2, the waste gas fully contacts with the absorption liquid, and the waste gas After the pollutants in the waste gas are absorbed by the absorption liquid, they ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com