Impact flow oil fume purification equipment and its reaction box

A technology for oil fume purification and impingement flow, which is applied in the removal of oil fume, lighting and heating equipment, applications, etc., can solve the problems of inconvenient disassembly and assembly, inconvenient cleaning of the reaction box, etc., to avoid costs, eliminate flue fire, disassembly and assembly. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

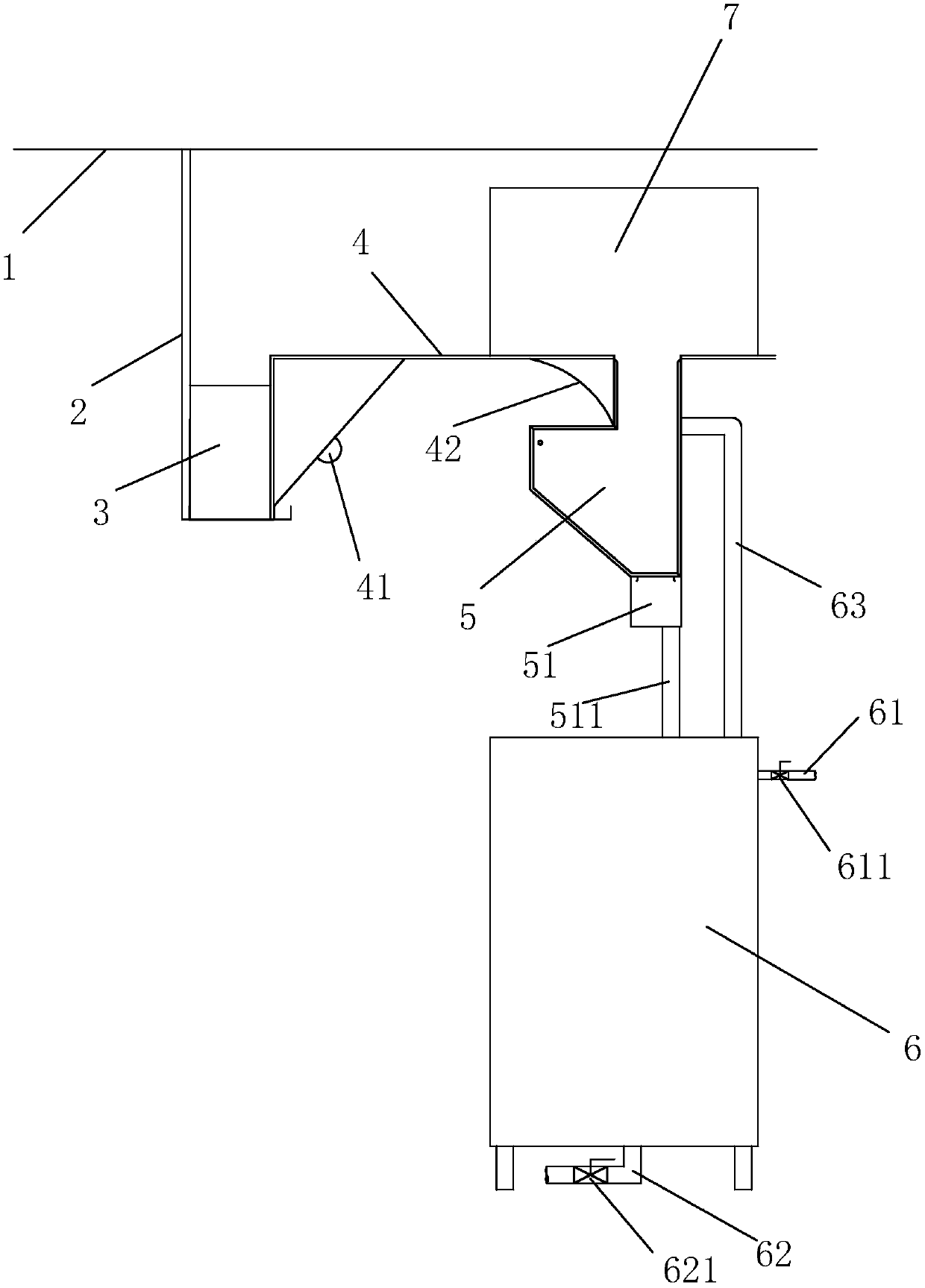

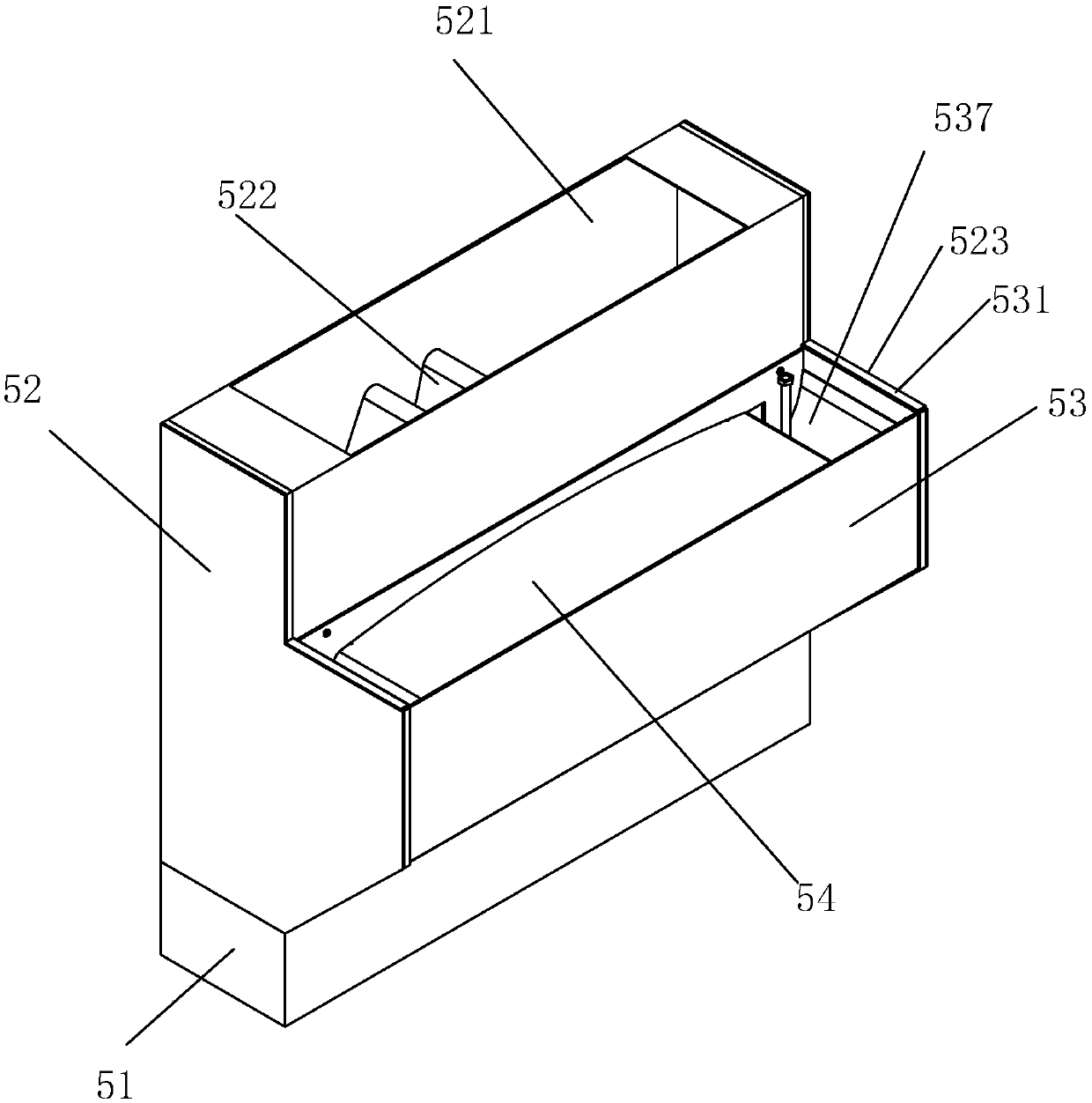

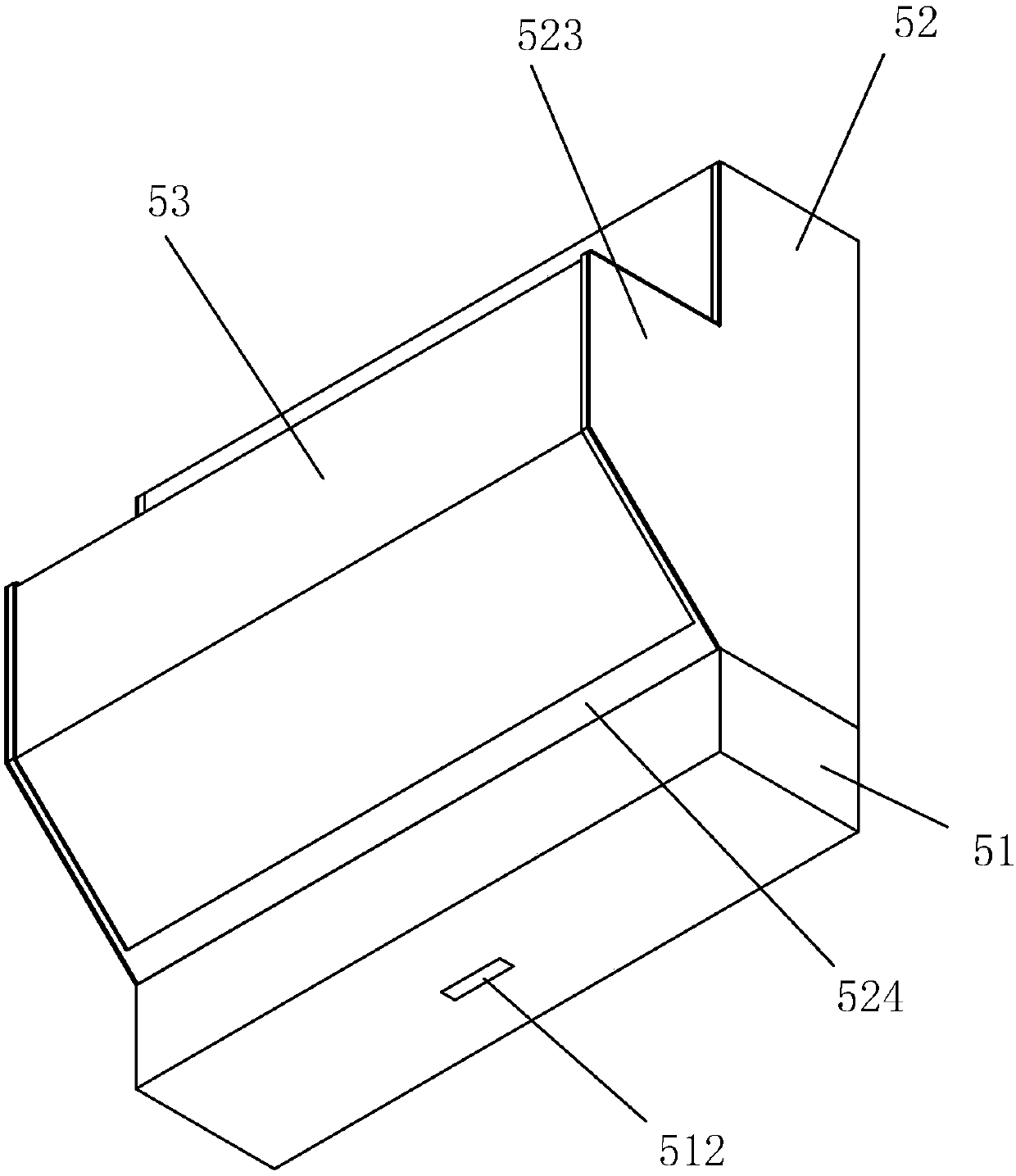

[0034] Embodiment: a kind of impinging flow type lampblack purifying equipment, such as figure 1 As shown, it includes a ceiling panel fixedly installed on the kitchen ceiling, a bracket 4 and a decorative panel 2 installed below the ceiling panel, a smoke exhaust pipe 7 is installed above the bracket 4, and a ventilation system is arranged between the bracket 4 and the side of the decorative panel 2. The air duct 3 is provided with a reaction box 5 below the support 4, a lamp 41 is provided on the side of the support 4 close to the air supply duct 3, and an outer deflector 42 is provided on the side of the support 4 close to the reaction box 5. The plate 42 is located above the reaction box 5 to guide the flue gas into the reaction box 5 . The bottom of the reaction tank 5 is set as a backwater tank 51, and the bottom of the backwater tank 51 is set as a liquid control tank 6. The back water tank 51 and the liquid control tank 6 are connected by a return pipe 511. The upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com