Cage type rotor eddy flow ultra-fine powder concentrator

A technology of cage-type rotor and eddy current, which is applied in swirl devices, devices in which the axial direction of the swirl can be reversed, and the separation of solids from solids by air flow, etc., can solve the problem of large average particle size, particle size Problems such as wide distribution range and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

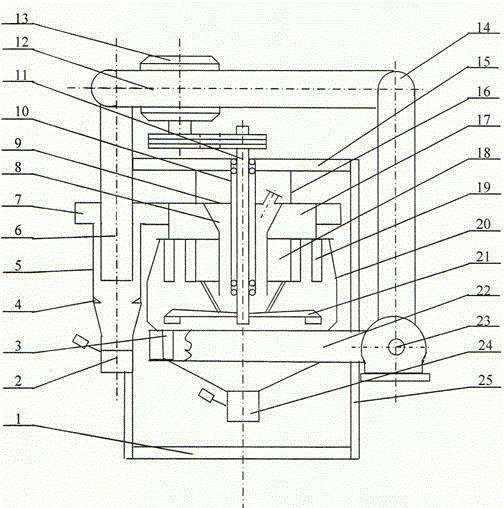

[0028] Specific implementation of structural arrangement

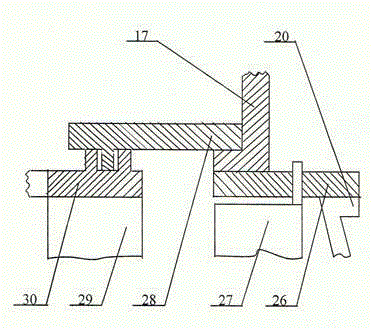

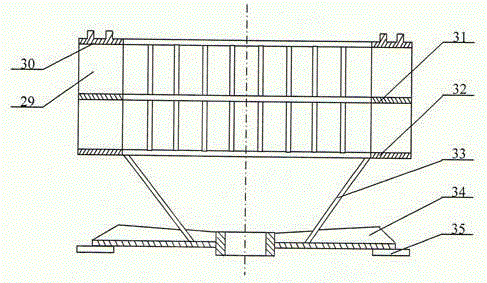

[0029] as attached figure 1As shown, the cage-type rotor eddy current ultra-fine powder separator designed by this patent is composed of a main engine frame, a feeding device, a power transmission device, a main engine housing (20), a spiral air inlet and return device, and an ultra-fine separation device. , cyclone gas-solid separation device, operation control box and other functional components. The well-shaped load-bearing beam (15), connecting beam, support column (25), and well-shaped foundation beam (1) of the main frame are welded and fixed into a rigid whole in the form of a frame structure by full-constraint welding, and fixed by hanging The frame (16) is welded and fixed vertically under the well-shaped load-bearing beam (15), the horizontal reference connecting plate (9) is welded and fixed on the hanging bracket (16), and the whole is installed through the well-shaped foundation beam (1) fixed to the equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com