Gradient polymer compositions for elastomeric wall and roof coatings

A water-based composition, the technology of the composition, applied in the direction of coating, etc., can solve the problems of failure to provide roof coatings, disclosure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0092] Example: The following examples illustrate the advantages of the invention. All temperature conditions are room temperature (22°C to 24°C) and all pressure units are 1 atmosphere, unless otherwise indicated.

[0093] testing method: The following test methods are used in the examples.

[0094] Mechanical properties: Tensile Maximum: Tested by ASTM D-2370 (December 2010); requires 1.4 minimum MPascal and the sample is 75mm long and 13mm wide, at 23°C with a gauge length of 25mm and a crosshead speed of 25mm / min Test; elongation at break: tested by ASTM D-2370 (December 2010), the sample is 75mm long and 13mm wide, tested at 23°C with a gauge length of 25mm and a crosshead speed of 25mm / min. At Weather-O-Meter TM After 1000 hours of accelerated weathering, the elongation must be 100% minimum.

[0095] Weather-O-Meter TM exposed: Weather-O-Meter TM The accelerated weathering method is the time period specified in ASTM D4798 (January 2011); the cycle used is A,...

example 3

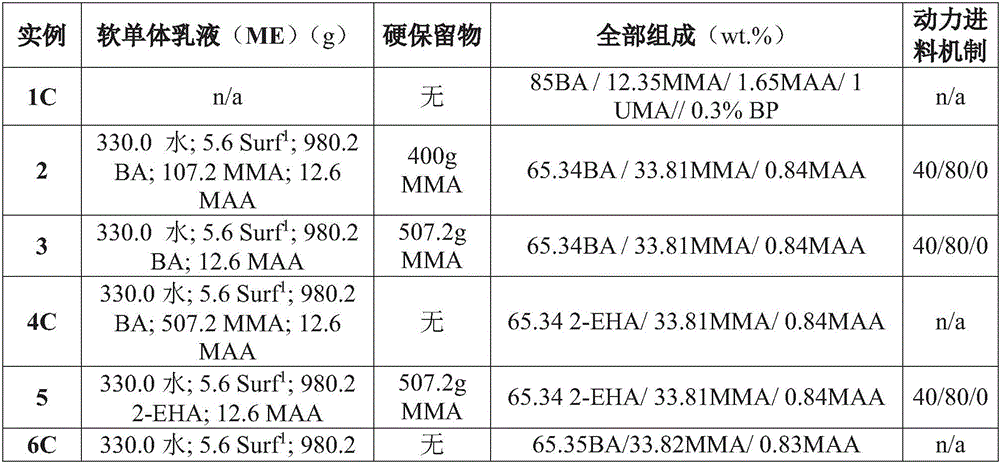

[0101] Example 3: Synthesis of Gradient Emulsion Copolymers by Power-Feed Emulsion Polymerization

[0102] Emulsion polymerization was carried out in a four necked 5 liter round bottom reaction flask equipped with a condenser, mechanical stir bar, thermocouple, monomer feed line, initiator feed line and nitrogen inlet in the following manner:

[0103] A reactor mixture containing 500 g of deionized water and 15 g of β-cyclodextrin was added to the flask and its contents were heated to 90° C. with stirring under a nitrogen purge. A solution containing 0.65 g of sodium carbonate dissolved in 20 g of water was added to the heated reactor mixture, followed by a solution containing 2.6 g of ammonium persulfate (APS) dissolved in 20 g of water, followed by addition of a solution containing A solution of 2.2 g of ammonia (28% aqueous solution) in 3.0 g of water was further added containing 89.5 g of acrylic acid seed emulsion polymer (Tg=17.5C, 1.5wt% MAA, 45wt.% solids, weight ave...

example 2

[0106] Example 2: Synthesis of Gradient Emulsion Copolymers by Power-Feed Emulsion Polymerization

[0107] The method of preparing the gradient emulsion copolymer of Example 3 was repeated according to the composition indicated in Table 1 below, except that a portion (21.1% or 107.2 g) of the hard monomer was added to the soft monomer container and only 78.9% or 400 g Hard monomer is added to the hard monomer container.

[0108] The product emulsion copolymer had a solids content in the range of 54 wt.% to 56 wt.% and a weight average particle size (BI90) of 302 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com