A hybrid DC ice-melting device with continuously adjustable output voltage and current

An output voltage, DC ice melting technology, applied in the installation of cables, harmonic reduction devices, electrical components, etc., can solve the problems of limited voltage withstand level, low reliability, and high cost, and reduce the number, capacity, structure, etc. Strong fault tolerance, small effect of grid-connected harmonic current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will take the hybrid DC ice-melting device whose output voltage and current can be continuously adjusted to realize the continuous adjustable output of the ice-melting voltage at 2-12.5kV DC voltage and the rated ice-melting capacity of 25MW as an example, and the output voltage and current of the present invention can be continuously adjusted. The hybrid DC ice melting device is further described in detail.

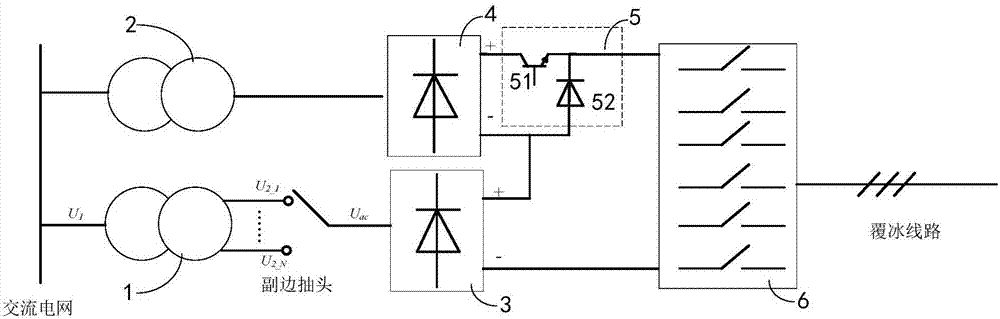

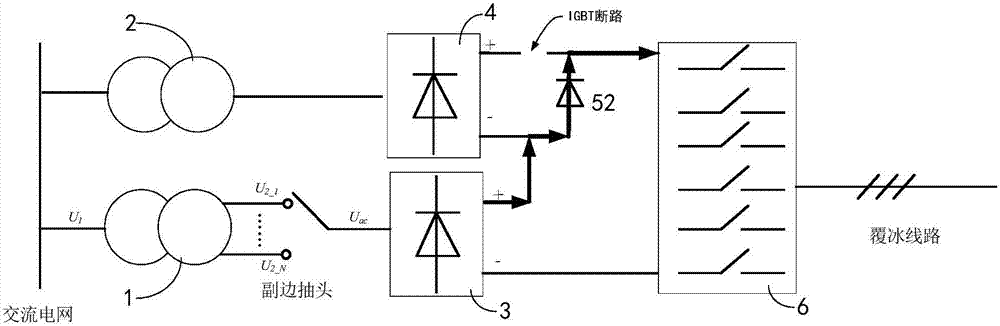

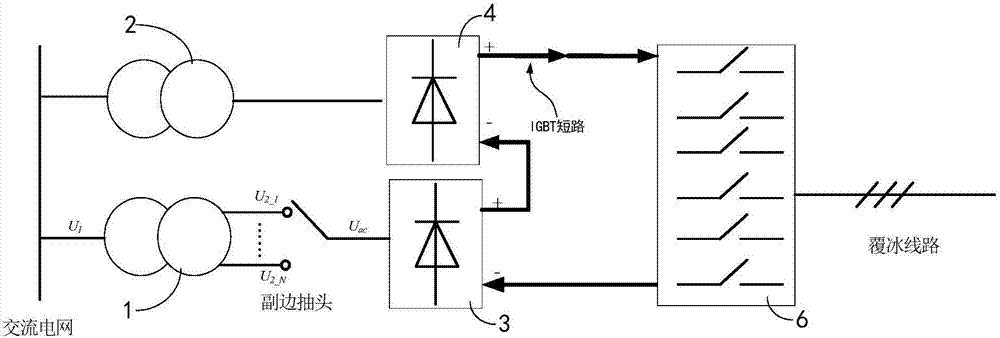

[0027] Such as figure 1 As shown, the hybrid DC ice-melting device with continuously adjustable output voltage and current in this embodiment includes a large-capacity adjustable ice-melting transformer 1, a small-capacity transformer 2, a primary non-controlled rectifier 3, a secondary non-controlled rectifier 4, a chopper regulator The voltage module 5 and the output knife switch 6, the primary side of the large-capacity adjustable ice-melting transformer 1 and the small-capacity transformer 2 are respectively connected to the AC power grid, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com