Numerical analysis method for influence of random shrinkage defect on mechanical property of casting

A numerical analysis and defect technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as random defects not involved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

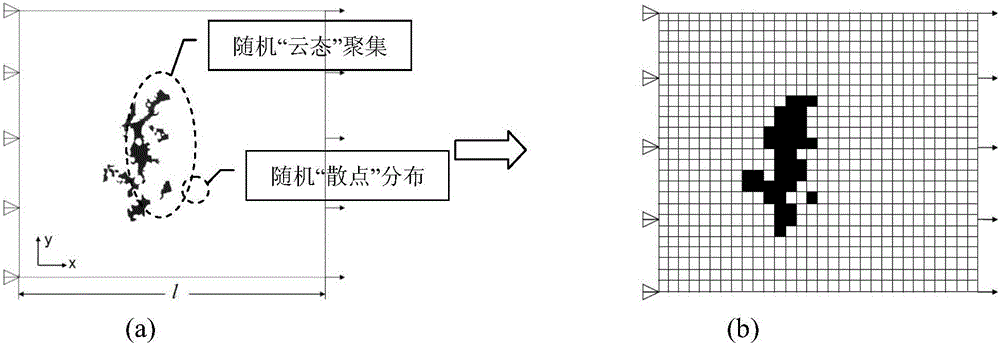

[0043] The present invention improves the random selection algorithm of the defect unit of the traditional lattice model, and establishes a numerical algorithm for simulating random shrinkage defects, by performing the following three steps (the flow chart is as follows: Figure 4 shown):

[0044] 1. Set a random rectangle (the size is m×n grid cells, where m is the number of rows and n is the number of columns, where m and n are a random integer generated by a random number generator) as the shrinkage defect "Envelope area", that is, all random shrinkage in the numerical model appears in this rectangular area, and we call this random rectangular area the shrinkage area.

[0045] 2. There is no shrinkage defect in the above shrinkage area at this time. This step executes the loop algorithm, selects some random units in the rectangular shrinkage area in 1, and as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com