Method for splicing photonic crystal fiber and single-mode fiber

A technology of photonic crystal fiber and single-mode fiber, which is applied in the coupling of optical waveguide, optics, light guide, etc., can solve the problems of uneven filling and low filling efficiency, improve the filling and welding efficiency, increase the mode field diameter, and apply wide-ranging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

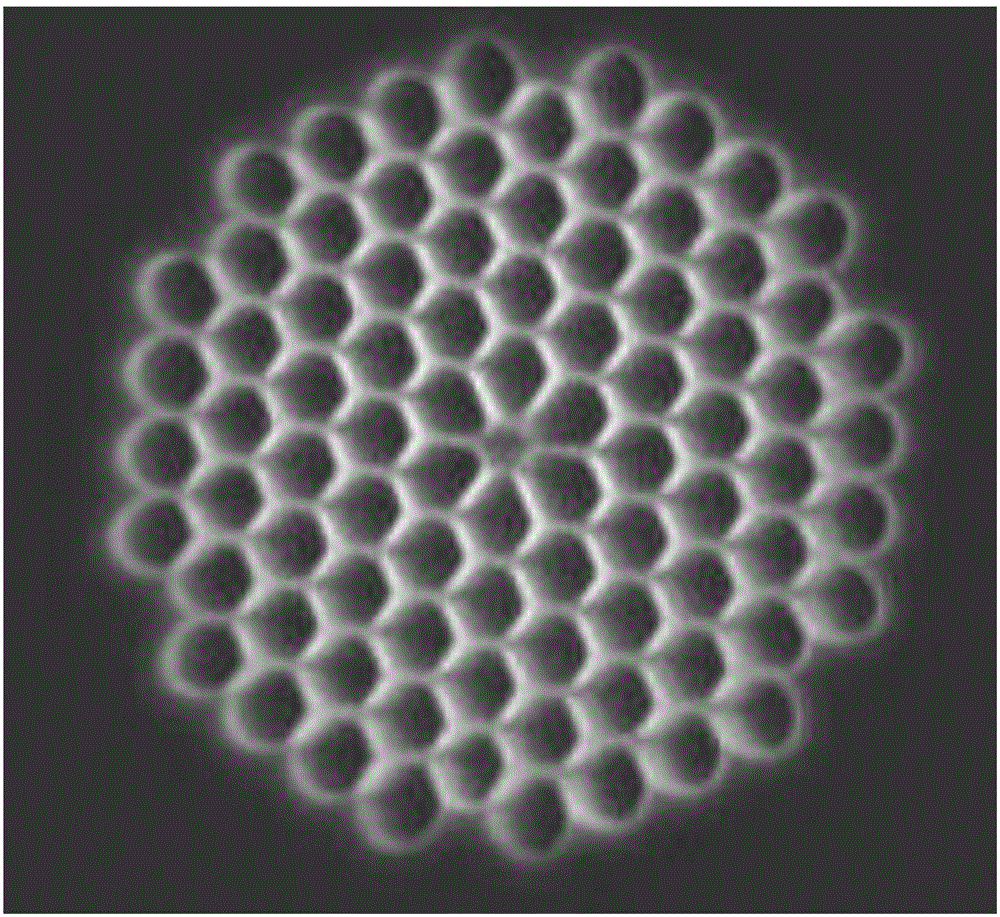

[0037] S1. The structure of the photonic crystal fiber 3 used in this embodiment is as follows figure 1 As shown, its parameters are fiber core diameter 2.43μm, air hole diameter 3.44μm, air hole spacing 3.93μm, air filling ratio 0.86;

[0038] Pretreatment is performed on the end of the photonic crystal fiber 3: sequentially including removing the fiber coating layer, cleaning with absolute ethanol, and cutting the end face.

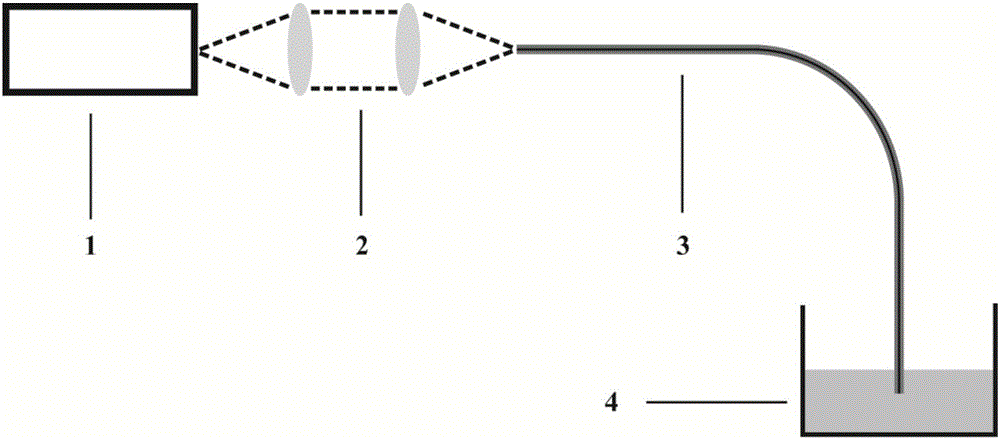

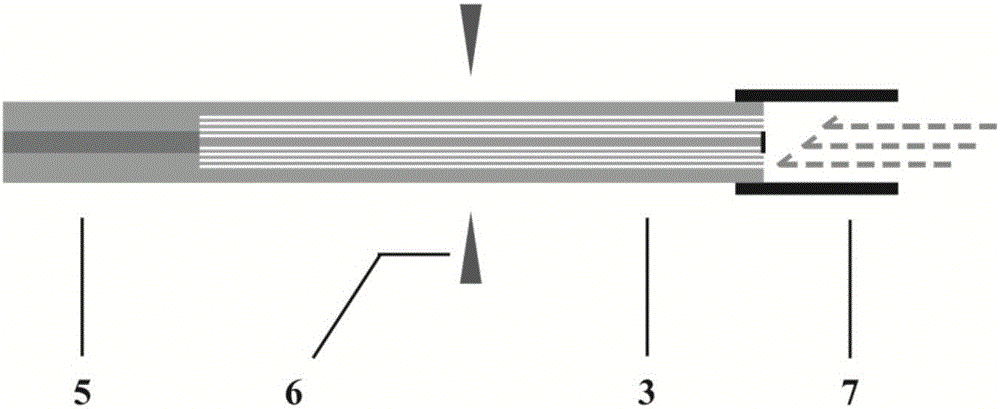

[0039] Then selectively fill the photonic crystal fiber: Here, UV-curable glue is used as the filling of the air hole in the photonic crystal fiber. see figure 2 As shown, the ultraviolet light source 1 with a wavelength of 365nm band couples the ultraviolet light into the photonic crystal fiber 3 through two convex lenses with a focal length of 8mm in the spatial light coupling system 2, and the output optical power of the fiber is about 50nW, and then connects one end of the photonic crystal fiber 1-2 mm is immersed in the ultraviolet curing glue 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com