In-situ test device for three-dimensional defect reconstruction

An in-situ test and defect technology, applied in the direction of measuring devices, using applied repetitive force/pulsation force to test material strength, using applied stable tension/pressure to test material strength, etc., can solve the problems that cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

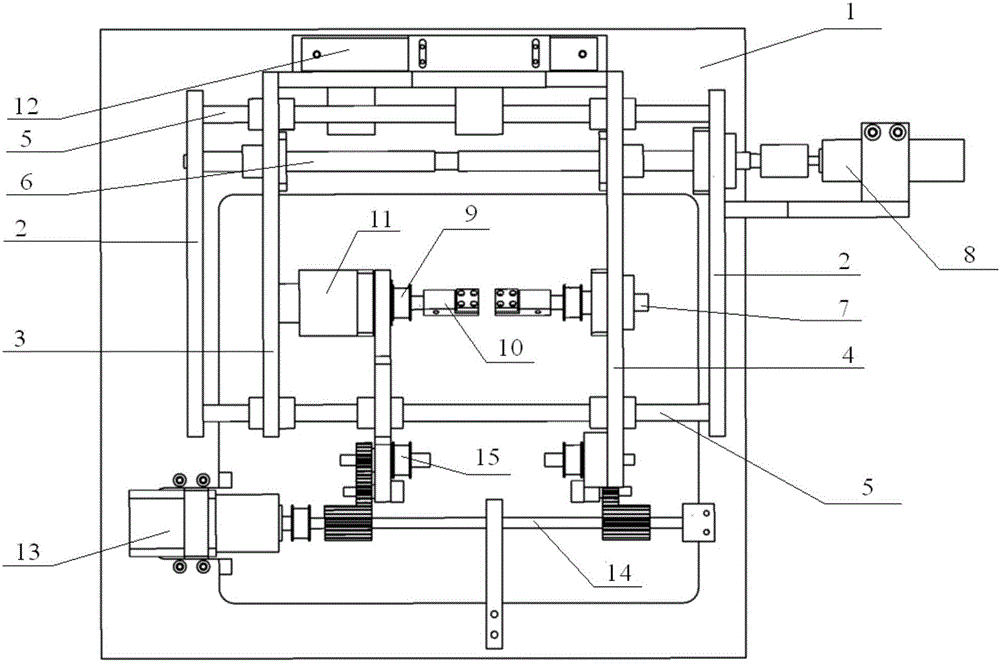

[0017] Below in conjunction with accompanying drawing, the present invention will be further described:

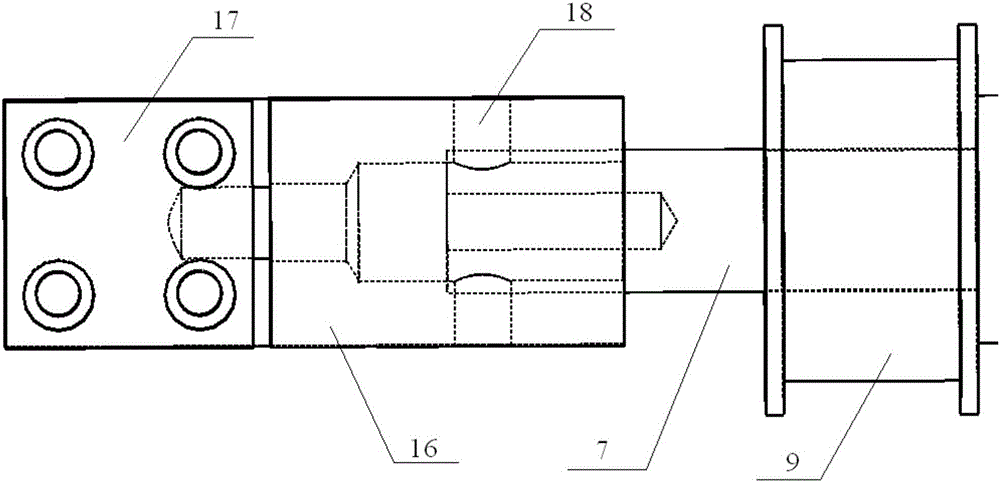

[0018] Such as Figure 1 to Figure 4 As shown, the in-situ test device for three-dimensional defect reconstruction includes a hollow frame structure 1 and a transmission mechanism. The frame structure 1 adopts a hollow structure to facilitate the passage of X-rays. The left and right sides of the frame structure 1 are respectively symmetrically provided with baffles 2, and the left beam 3 and the right beam 4 are slidably connected between the baffles 2 through the guide rail 5, and the left beam 3 and the right beam are also provided between the baffles 2. The rotating lead screw 6 connected with the beam 4, the two ends of the rotating lead screw 6 are provided with reverse threads, one side of the frame structure 1 is provided with a pulling motor 8 connected with the rotating lead screw 6, and the stretching motor 8 drives the two The rotating screw rod 6 with reverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com