Boiler fully utilizing smoke gas waste heat

A flue gas waste heat and boiler technology, applied in the direction of air heaters, preheating, water heaters, etc., can solve the problems of low heat transfer efficiency, poor heat transfer effect, damage, etc., and achieve heat saving, effective heat energy, and work efficiency Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

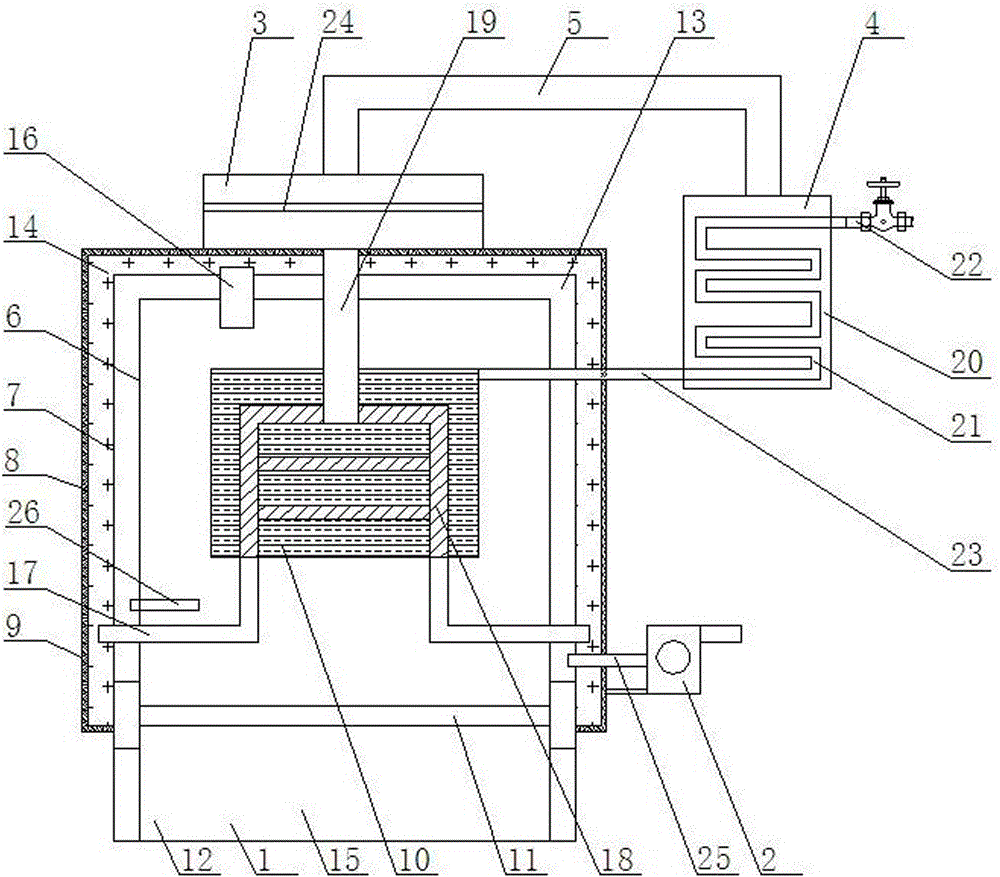

[0020] Such as figure 1 As shown, a boiler that makes full use of the waste heat of flue gas includes a furnace body 1, a blast device 2, a flue gas chamber 3, and a preheating water tank 4. Chamber 3, the flue gas chamber 3 is connected to the preheating water tank 4 through the gas delivery pipe 5; the interior of the furnace body 1 is composed of an inner shell 6, a middle shell 7, an outer shell 8, and a thermal insulation shell 9; The interior of the shell 6 is a combustion chamber 15, which is installed in the center of the furnace body 1. The internal device is a heating water tank 10, a fire grate 11, and an ash chamber 12. The fire grate 11 is installed at the lower end of the inner shell 6. The fire grate The lower end of 11 is the ash chamber 12, and the heating water tank 10 is installed at the upper end of the inner shell 6; the air preheating chamber 13 is formed between the middle shell 7 and the inner shell 6; the outer shell 8 and the middle shell A flue g...

Embodiment 2

[0022] Such as figure 1 As shown, the left side of the top of the combustion chamber 15 is connected to the flue gas circulation chamber 14 through the first smoke exhaust pipe 16, and the left lower end and the right lower end of the flue gas circulation chamber 14 are respectively connected to the combustion chamber 15 through a flue gas delivery pipe 17. The internal heating water tank 10 is equipped with a heat exchange device 18 inside the heating water tank 10. The lower end of the heat exchange device 18 is connected to two flue gas delivery pipes 17, and the upper end is equipped with a second smoke exhaust pipe 19. The second smoke exhaust pipe 19 The upper end is connected with the flue gas chamber 3 .

Embodiment 3

[0024] Such as figure 1 As shown, the blower device 2 is connected to the right lower end of the air preheating chamber 13 through the cold air delivery pipe 25 , and the left lower end of the air preheating chamber 13 is connected to the combustion chamber 15 through the preheating air delivery pipe 26 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com