Novel hypersonic flame spraying gun

A flame spray gun, ultra-high technology, applied in the field of new supersonic flame spray gun, can solve the problems of breakthroughs in liquid fuel and oxygen, and achieve simple structure, avoid carbon deposition, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

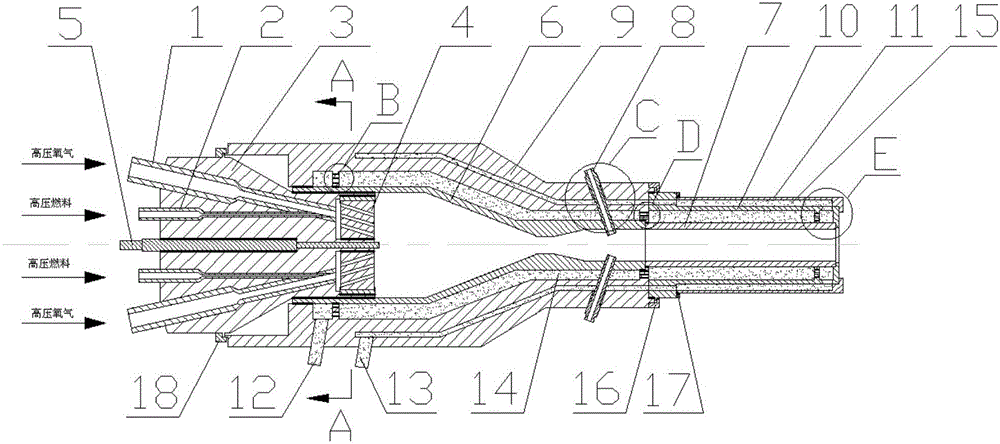

[0030] figure 1 Shown is a preferred embodiment of the novel hypersonic flame spray gun of the present invention, but not limited thereto. Such as figure 1 As shown, it includes two high-pressure oxygen input pipes 1, two high-pressure liquid fuel input pipes 2, a coaxial tailstock 3, a catalytic ceramic sheet 4, an ignition needle 5, a combustion chamber 6, a gun barrel 7, a powder feeding needle 8, and a combustion chamber. Chamber housing 9, barrel housing 10, water cooling jacket 11, cooling water inlet 12, cooling water outlet 13, water cooling passage 14, return water passage 15, locking screw sleeve 16,17,18.

[0031] The coaxial tailstock 3 is installed at the tailmost end of the spray gun, and the front part is inserted into the combustion chamber 6 and kept sealed with the inner wall of the combustion chamber. The coaxial tailstock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com