Return oil diversion system for telescopic boom oil cylinder of high altitude work vehicle

A high-altitude operation vehicle and shunt system technology, which is applied in the field of oil return and shunt system of the telescopic arm cylinder of the aerial work vehicle, can solve the problems of slow retraction of the oil cylinder, energy loss, and vibration of the oil cylinder, so as to reduce the oil return back pressure and prevent retraction Vibration, the effect of eliminating pressure shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

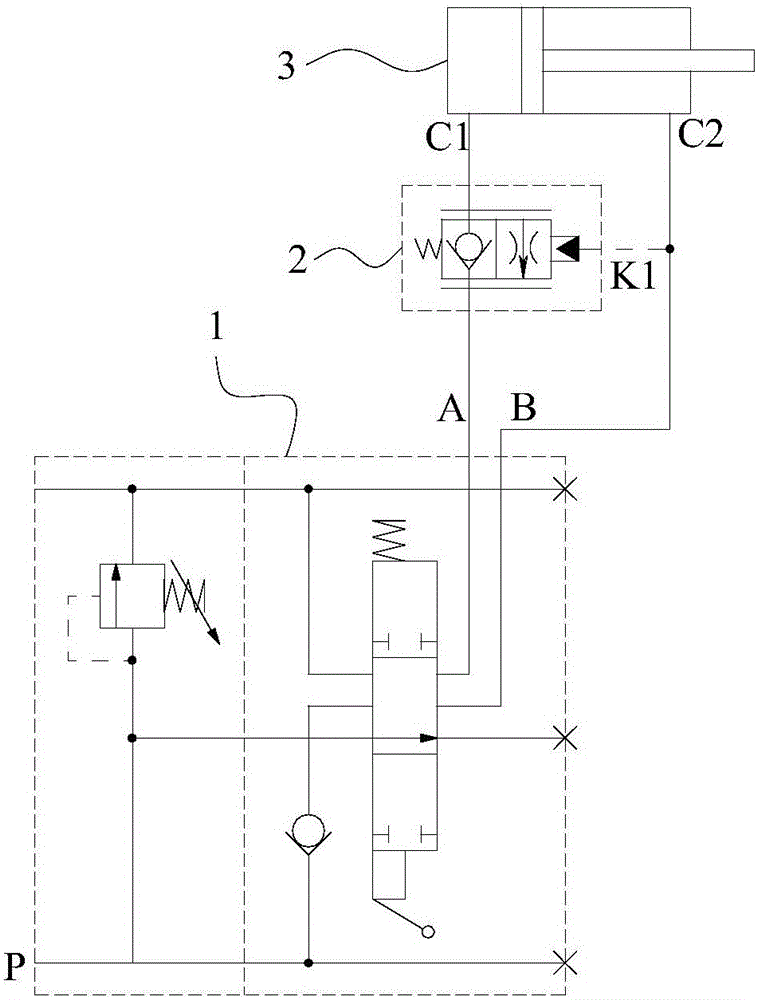

Embodiment 1

[0022] The principle of the telescopic arm cylinder oil return and distribution system of the aerial work vehicle is as follows figure 2 As shown, it includes multi-way reversing valve 1, balance control valve 2 and oil cylinder 3. Port A of multi-way directional control valve 1 is connected to rodless chamber oil port C1 of oil cylinder 3 through balance control valve 2. The multi-way reversing valve Port B of valve 1 is connected with the control port K1 of balance control valve 2 and the oil port C2 of the rod chamber of oil cylinder 3, and the oil port C2 of the rod chamber of oil cylinder 3 is connected with the control port K1 of balance control valve 2. A throttle valve 4 and a balance oil return valve 5 are connected in series between ports A and B of the multi-way reversing valve 1, and the control port K2 of the balance oil return valve 5 is connected to the B port of the multi-way reversing valve 1 , The throttle valve 4 and the balance oil return valve 5 are all c...

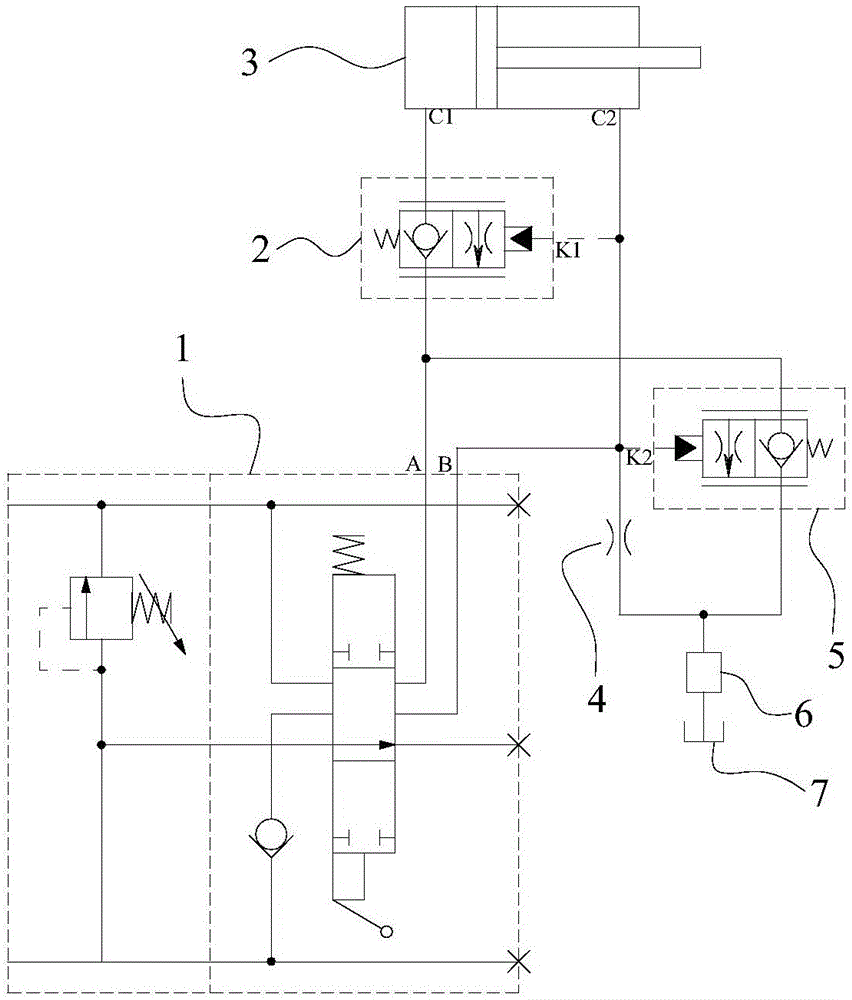

Embodiment 2

[0024] The principle of the telescopic arm cylinder oil return and distribution system of the aerial work vehicle is as follows image 3 As shown, it includes a multi-way reversing valve 1, a balance control valve 2 and an oil cylinder 3. The balance control valve 2 is a hydraulically controlled speed-limiting balance valve, and the A port of the multi-way reversing valve 1 communicates with the oil cylinder through the balance control valve 2 The oil port C1 of the non-rod chamber of 3 is connected, the B port of the multi-way reversing valve 1 is connected with the control end K1 of the balance control valve 2 and the oil port C2 of the rod chamber of the cylinder 3, and the oil port of the rod chamber of the cylinder 3 Port C2 is connected to the control port K1 of the balance control valve 2, and a throttle valve 4 and a balance oil return valve 5 are connected in series between the A port and the B port of the multi-way reversing valve 1. Valve 5 is a hydraulically contro...

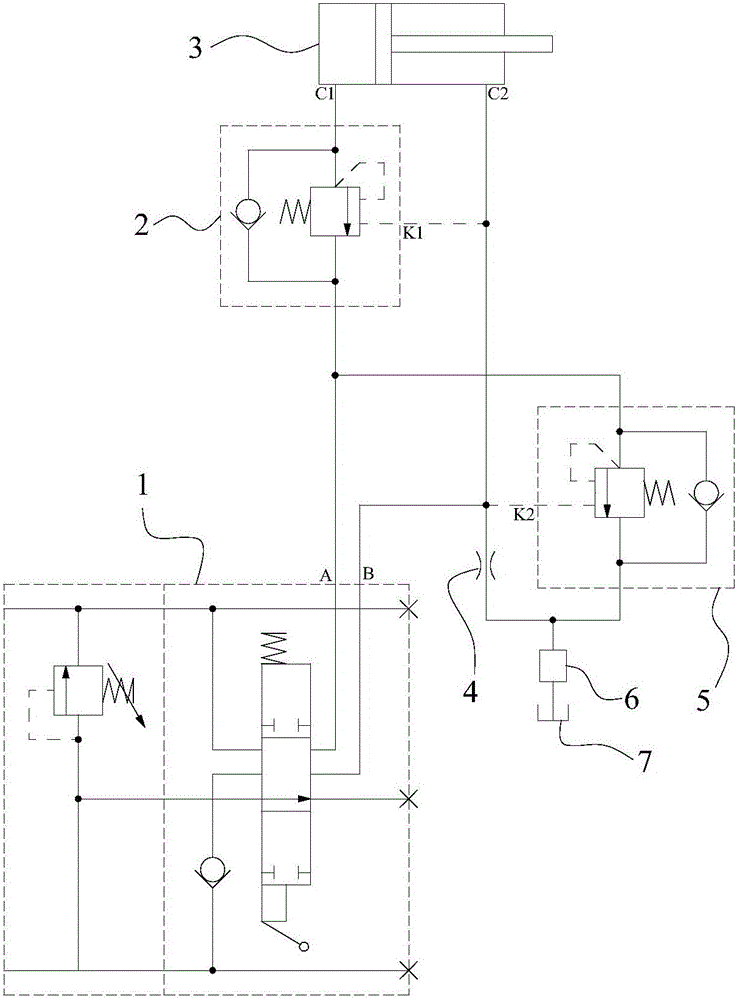

Embodiment 3

[0026] The principle of the telescopic arm cylinder oil return and distribution system of the aerial work vehicle is as follows Figure 4 As shown, it includes a multi-way reversing valve 1, a balance control valve 2 and an oil cylinder 3. The balance control valve 2 is a two-way balance valve. The oil port C1 of the non-rod chamber of 3 is connected, the B port of the multi-way reversing valve 1 is connected with the rod chamber oil port C2 of the oil cylinder 3 through the V2 port of the balance control valve 2, and the A port of the multi-way reversing valve 1 A throttle valve 4 and a balance oil return valve 5 are also connected in series between the B port. The balance oil return valve 5 is a hydraulically controlled speed-limiting balance valve, and the control terminal K2 of the balance oil return valve 5 is connected to the Port B of valve 1 is connected, and both throttle valve 4 and balance oil return valve 5 are connected to oil tank 7 through on-off valve 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com