Method for increasing success rate of chemical plugging of leaking casing damage well

A technology with high success rate and chemistry, applied in chemical instruments and methods, earthwork drilling, sealing/isolation, etc., can solve the problems of poor plugging agent retention, short validity period, low pass rate, etc., and improve the pressure bearing capacity of the formation , prolong the validity period, and improve the success rate of plugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

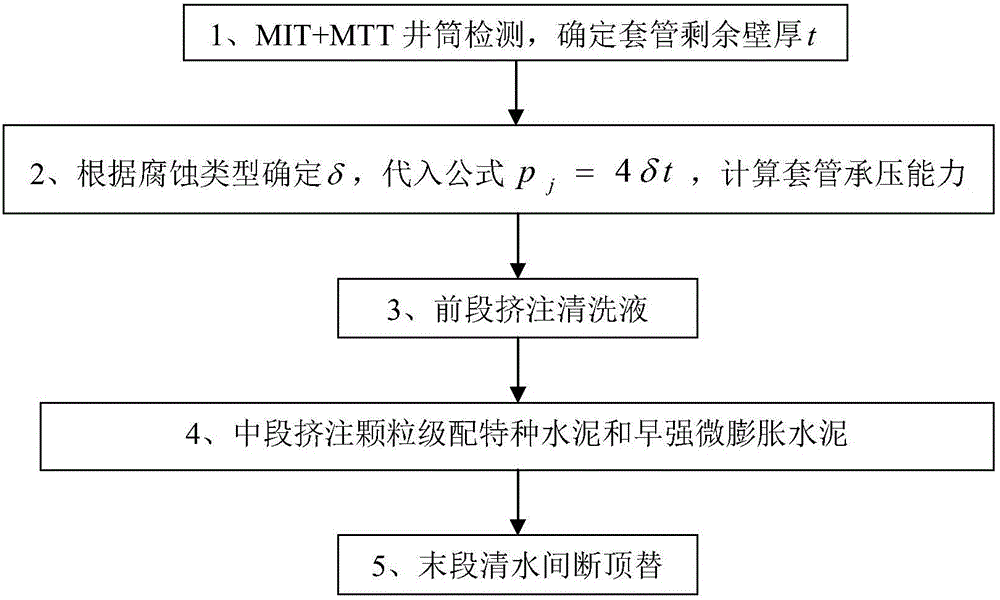

[0034] In order to overcome the problems of poor retention of plugging agent in chemical plugging of lost casing damaged wells, low pass rate of 15MPa pressure test after plugging, and short validity period after passing the pressure test, this embodiment provides a method such as figure 1 The method shown to increase the success rate of chemical plugging in leaky casing damaged wells, for the casing damaged wells whose casing damage is within 1000m, can be one casing damage point or multiple casing damage points. The casing damaged well with a length of less than 100m can basically be successfully completed at one time, including the following steps:

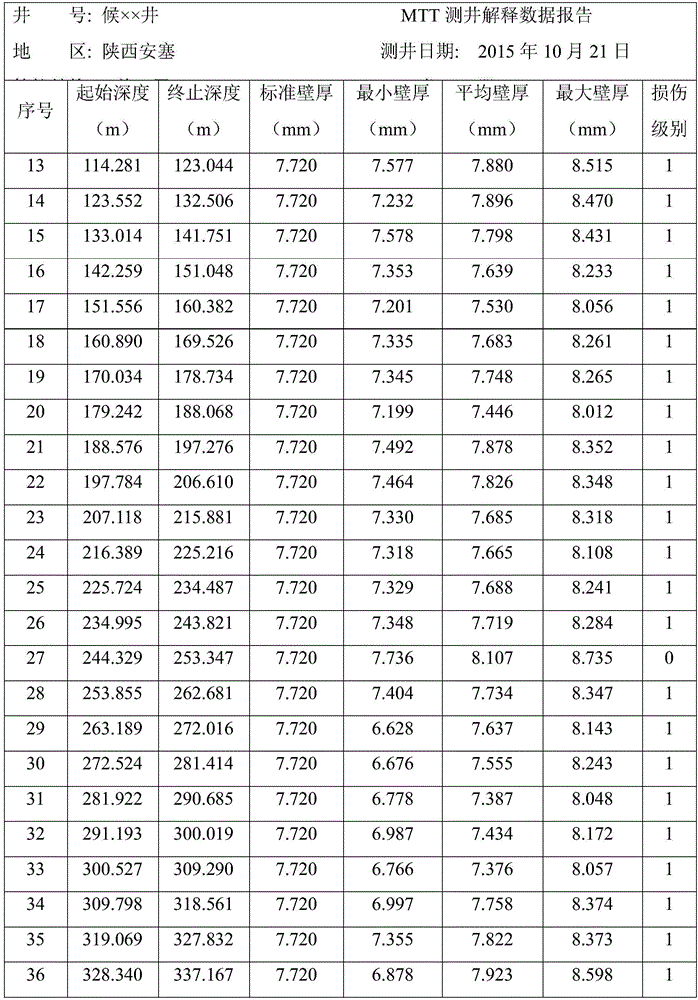

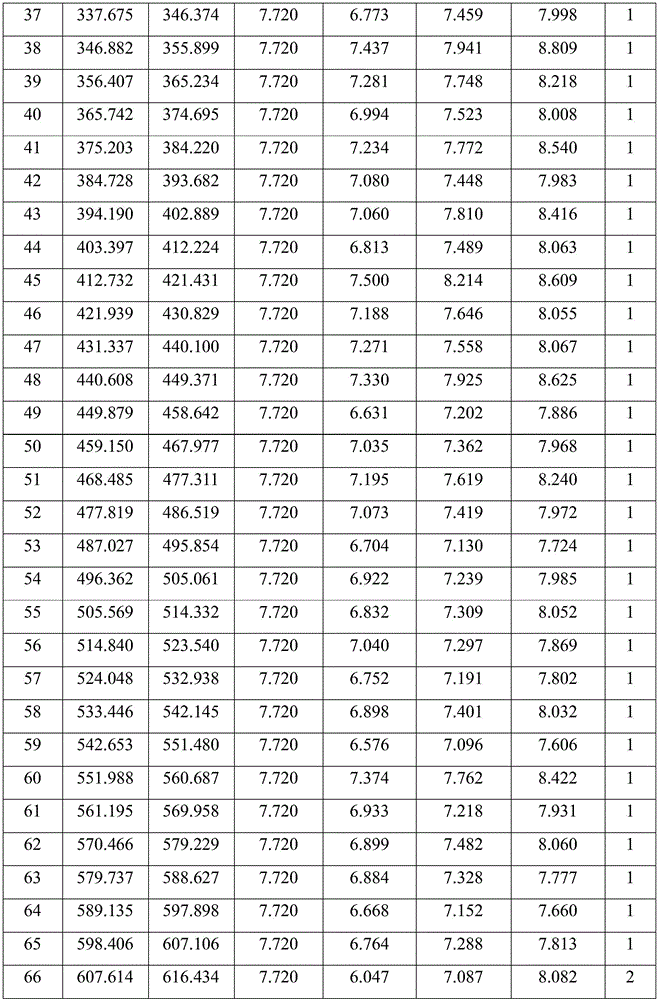

[0035] Step 1) Determine the remaining wall thickness t of the casing according to the MIT+MTT wellbore detection;

[0036] Step 2) calculate casing pressure bearing capacity;

[0037] Step 3) Squeeze 20m at the front section of casing 3 Cleaning liquid, cleaning slug, cleaning casing outer wall oil and corrosion products;

...

Embodiment 2

[0042] On the basis of Example 1, this example provides a method for improving the success rate of chemical plugging of leaky casing damaged wells. In the step 1), MIT is a multi-arm caliper imager, which is a well developed by the British Sondex company. The diameter imaging logging tool can detect the inner diameter of the casing, and the MTT is a magnetic wall thickness logging tool, which is a casing wall thickness damage imaging logging tool developed by the British Sondex company, which can detect the remaining casing wall thickness.

Embodiment 3

[0044] On the basis of Embodiment 2, this embodiment provides a method for improving the success rate of chemical plugging of leakage casing damaged wells. In the step 2), the pressure bearing capacity of the casing is calculated according to the formula: p j =4δt

[0045] In the formula: p j , casing pressure, MPa;

[0046] t, remaining wall thickness of casing, obtained from well logging, mm;

[0047] δ: circumferential uneven corrosion coefficient.

[0048]The circumferential uneven corrosion coefficient δ is related to the corrosion mechanism and time. When it is uniform corrosion of sheet and step, δ is 0.8-0.9, and when it is localized corrosion of point and groove, δ is 0.7-0.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com