Pressure-bearing plugging slurry as well as preparation method and application thereof

A technology of plugging slurry and plugging agent, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve problems such as poor resistance to drilling fluid erosion and pressure shock, and improve the success rate and impact resistance, reduced permeability, reduced time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

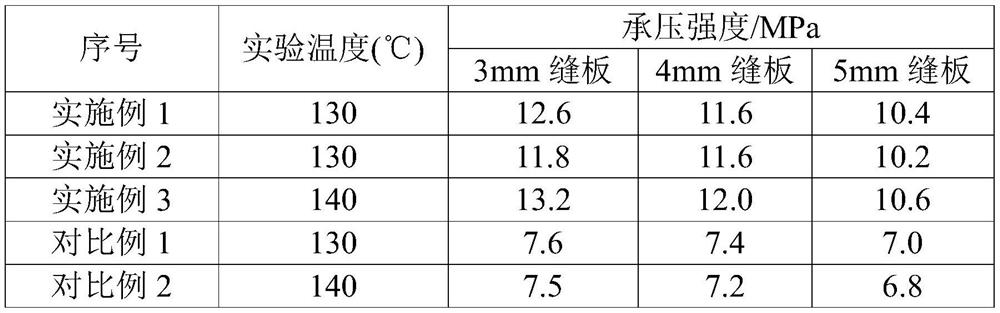

Examples

Embodiment 1

[0047] The dosage of each component of the pressure-bearing leakage plugging slurry is as follows in parts by weight:

[0048] Well mud: 100

[0049] High strength plugging agent GQJ-1: 12

[0050] Elastic plugging agent SMGQ-3:6

[0051] Fiber plugging agent SQD-98: 3

[0052] Asphalt powder for drilling fluid FF-1:2

[0053] Micro-nano plugging agent SMNR-1:2

[0054] Film-forming plugging agent SMFP-1:1

[0055] in,

[0056] The well mud is potassium amine-based polysulfide drilling fluid, and the specific system formula is: 3% bentonite slurry + 2% sulfonated phenolic resin SMP-2 + 2% lignite resin SPNH + 3% sulfonated lignite SMC + 2% sulfonated Asphalt powder FT-1+2% cationic emulsified asphalt YK-H+2% nanoemulsion RHJ-3+1% polyamine SMJA-1+5% potassium chloride KCl+barite, drilling fluid density is 1.38g / cm 3 , the viscosity is 50s.

[0057] The preparation method of the pressure-bearing plugging slurry comprises the following steps:

[0058] Take the well mud,...

Embodiment 2

[0062] The dosage of each component of the pressure-bearing leakage plugging slurry is as follows in parts by weight:

[0063] Well mud: 100

[0064] High strength plugging agent GQJ-2: 10

[0065] Elastic plugging agent SMGQ-3:5

[0066] Fiber plugging agent DF-1: 2.5

[0067] Asphalt powder for drilling fluid FT-342: 2.5

[0068] Micro-nano plugging agent SMNR-1:3

[0069] Film-forming plugging agent SMFP-1: 1.5

[0070] The preparation method of the pressure-bearing plugging slurry is the same as in Example 1.

[0071] The well mud is potassium amine polysulfonate drilling fluid, and its specific system formula includes: 3% bentonite mud + 2% SMP-2 + 2% SPNH + 3% SMC + 2% FT-1 + 2% YK-H + 2%RHJ-3+1%SMJA-1+5%K Cl+barite, drilling fluid density is 1.38g / cm 3 , The viscosity is 54s.

[0072] Leakage occurred at 6016m at the bottom of the well, with a leakage rate of 12m 3 / h, prepare 50m according to the above formula 3 Pressure-bearing plugging slurry, and use the d...

Embodiment 3

[0075] The dosage of each component of the pressure-bearing leakage plugging slurry is as follows in parts by weight:

[0076] Well mud: 100

[0077] High strength plugging agent GQJ-2: 16

[0078] Elastic plugging agent SMGQ-3: 8

[0079] Fiber plugging agent DF-1:4

[0080] Asphalt powder for drilling fluid FT-1:4

[0081] Micro-nano plugging agent SMNR-1:3

[0082] Film-forming plugging agent SMFP-1:2

[0083] The preparation method of the pressure-bearing plugging slurry is the same as in Example 1.

[0084] The well mud is potassium amine polysulfonate drilling fluid, and its specific system formula includes:

[0085] 3% bentonite slurry + 2% SMP-2 + 2% SPNH + 3% SMC + 2% FT-1 + 2% YK-H + 2% RHJ-3

[0086] +1%SMJA-1+5%KCl+barite, drilling fluid density is 1.38g / cm 3 , The viscosity is 53s.

[0087] The leakage occurred at 6558m at the bottom of the well, and the leakage rate was 32m 3 / h, prepare 60m according to the above formula 3 Pressure-bearing plugging sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com