Drilling fluid system for improving formation conditions as well as preparation method and application of drilling fluid system

A technology for formation conditions and drilling fluids, applied in chemical instruments and methods, earthmoving drilling, flushing wellbore, etc., can solve the prominent contradiction between rheology and filtration loss and wall-building, serious drilling fluid thickening phenomenon, and drilling fluid performance Deterioration and other problems, to achieve the effects of good wellbore stability, enhanced pressure bearing capacity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

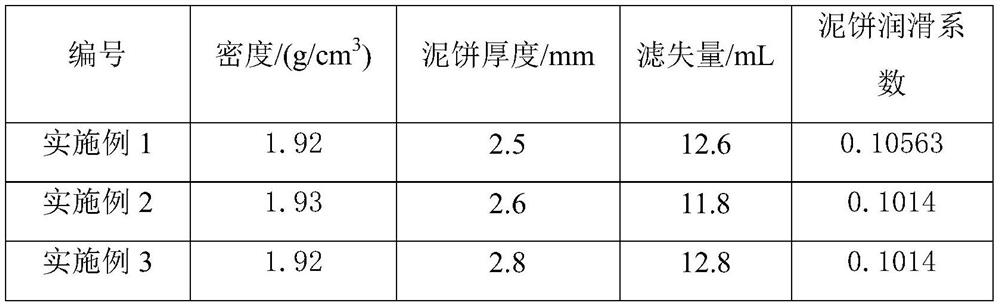

Embodiment 1

[0026] A method for preparing a drilling fluid system for improving formation conditions, comprising the following steps:

[0027] (1) configure the drilling fluid, the drilling fluid is based on 100 parts by weight of water, the content of the bentonite is 4 parts by weight, the content of the low-viscosity anionic cellulose is 2 parts by weight, and the content of the polyamine The content is 0.5 parts by weight, the content of the sulfonated phenolic resin (II) is 5 parts by weight, the content of the SMC is 4 parts by weight, the content of the anhydrite is 0.6 parts by weight, and the content of the NaOH is 0.5 parts by weight, the content of the lignite resin is 4 parts by weight, the content of the potassium chloride is 6 parts by weight, the content of the high temperature and salt resistance fluid loss reducer is 0.8 parts by weight, the silanol inhibitor The content of the film-forming agent is 0.5 parts by weight, the content of the film-forming agent is 0.3 parts b...

Embodiment 2

[0034] A method for preparing a drilling fluid system for improving formation conditions, comprising the following steps:

[0035] (1) configure the drilling fluid, the drilling fluid is based on 100 parts by weight of water, the content of the bentonite is 4.5 parts by weight, the content of the low-viscosity anionic cellulose is 2.3 parts by weight, and the content of the polyamine The content is 0.6 parts by weight, the content of the sulfonated phenolic resin (II) is 5.6 parts by weight, the content of the SMC is 5.5 parts by weight, the content of the anhydrite is 0.65 parts by weight, and the content of the NaOH is 0.5 parts by weight, the content of the lignite resin is 5.8 parts by weight, the content of the potassium chloride is 8 parts by weight, the content of the high-temperature and salt-resistant fluid loss reducer is 0.55 parts by weight, the silanol inhibitor The content of the film-forming agent is 0.7 parts by weight, the content of the film-forming agent is ...

Embodiment 3

[0042] A method for preparing a drilling fluid system for improving formation conditions, comprising the following steps:

[0043] (1) configure drilling fluid, the drilling fluid is based on 100 parts by weight of water, the content of the bentonite is 3.6 parts by weight, the content of the low-viscosity anionic cellulose is 0.8 parts by weight, and the content of the polyamine The content is 0.55 parts by weight, the content of the sulfonated phenolic resin (II) is 6.5 parts by weight, the content of the SMC is 4.5 parts by weight, the content of the anhydrite is 0.6 parts by weight, and the content of the NaOH is 0.6 parts by weight, the content of the lignite resin is 5.5 parts by weight, the content of the potassium chloride is 6 parts by weight, the content of the high temperature and salt fluid loss reducer is 1.1 parts by weight, the silanol inhibitor The content of the film-forming agent is 0.6 parts by weight, the content of the film-forming agent is 0.75 parts by w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com