Drilling fluid for improving formation pressure bearing capacity and its preparation method and application

A technology of pressure-bearing capacity and drilling fluid, which is applied in the field of drilling fluid and its preparation to improve the pressure-bearing capacity of formations. It can solve problems such as low pressure-bearing capacity of formations, sticking drill sticks, and lost circulation, so as to improve the pressure-bearing capacity of formations. , Enhanced anti-stick performance and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The second aspect of the present invention provides a method for preparing the drilling fluid for improving formation pressure bearing capacity according to the present invention, wherein the preparation method includes the following steps:

[0041] (1) Carry out prehydration treatment to bentonite, obtain prehydration bentonite slurry;

[0042] (2) Add low-viscosity polyanionic cellulose, lignite resin, high temperature and salt-resistant fluid loss reducer, silanol inhibitor, inorganic micro-nano rigid particles and emulsified pitch to the pre-hydrated bentonite slurry obtained in step (1), Stir to obtain the drilling fluid.

[0043] According to the present invention, the conditions of the prehydration treatment include: under the first stirring condition, adding 3-5 parts by weight of bentonite to 100 parts by weight of water to obtain a mixture; under the second stirring condition, adding The soda ash is mixed and allowed to stand to obtain a prehydrated bentonite s...

Embodiment 1

[0064] Measure 100 parts by weight of water, under electric stirring at a low speed of 1000r / min, add 4 parts by weight of bentonite, stir for 3 hours and add 0.10 parts by weight of Na 2 CO 3 , stirred for another 3 hours, and stood at room temperature for 24 hours for prehydration treatment; under high-speed 5000r / min electric stirring, add 0.5 parts by weight of low-viscosity anionic cellulose PAC-LV, stir for 15 minutes, add 5 parts by weight of the filter Add 0.2 parts by weight of lignite resin SPNH and stir for 10 minutes, add 0.8 parts by weight of anti-high temperature and anti-salt fluid loss reducer BDF-100S, 0.5 parts by weight of silanol inhibitor and high-efficiency silanol viscosity reducer, Stir for 15 minutes, add 1 weight part of inorganic micro-nano rigid particles I, 1 weight part of inorganic micro-nano rigid particles II and stir for 15 minutes, add 2 weight parts of emulsified pitch EP-2 and stir for 15 minutes, add 400 weight parts of weighting agent ba...

Embodiment 2

[0067] The drilling fluid is prepared according to the same method as in Example 1, except that 1 part by weight of inorganic micro-nano rigid particles I used in Example 1 is replaced by 1.5 parts by weight of inorganic micro-nano rigid particles I; 1 weight part of inorganic micro-nano rigid particle II was replaced by 1.5 weight part of inorganic micro-nano rigid particle II to prepare drilling fluid.

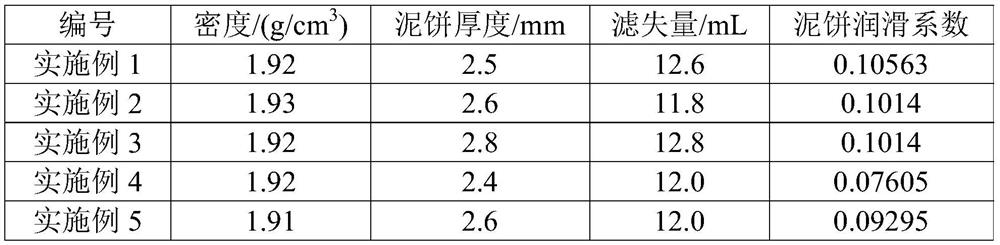

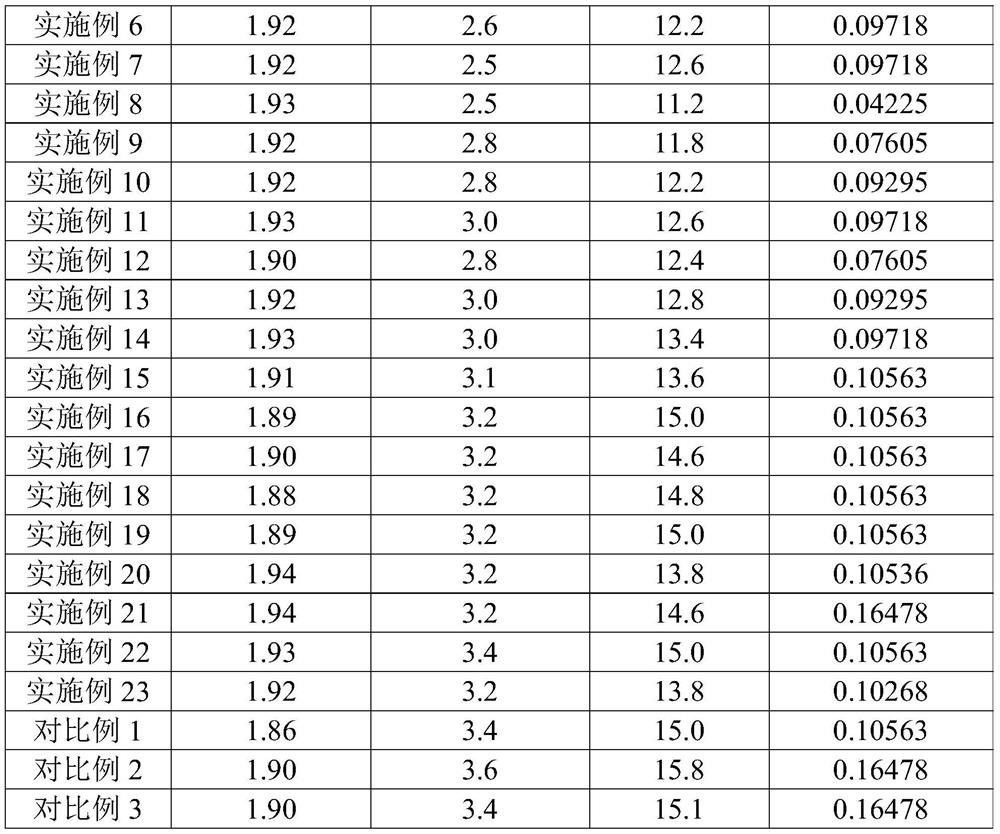

[0068] The results of high temperature and high pressure (HTHP) fluid loss test and mud cake performance test of the drilling fluid are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com