Preparation method of aqueous polyurethane coating with modified kaolin as filler

A technology of water-based polyurethane and kaolin, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as serious environmental hazards, achieve obvious improvement in comprehensive performance, good storage stability, and simple ball milling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

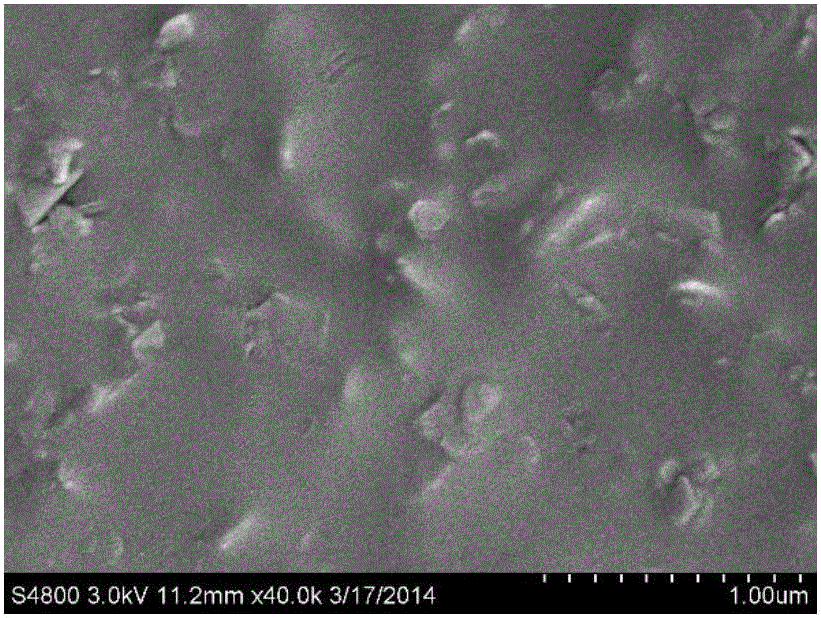

Image

Examples

Embodiment 1

[0030] A kind of preparation method taking modified kaolin as the waterborne polyurethane coating of filler, comprises the following steps:

[0031] (1) Disperse 60 g of uncalcined kaolin and 0.9 g of bis(dioctylpyrophosphate acyloxy)ethylene titanate in 120 ml of absolute ethanol; grind for 1 hour at a ball mill speed of 200 r / min, and recover anhydrous ethanol, and dried in an oven at 50°C for 24 hours to obtain a hydrophilic modified kaolin.

[0032] (2) Mix 85g of water-based polyurethane, 15g of hydrophilic modified kaolin, 0.5g of water-based silicone defoamer and 1.5g of non-ionic water-based polyurethane thickener; ball mill and disperse for 1h under the condition of planetary ball mill speed 200r / min to obtain improved Waterborne polyurethane coating with non-toxic kaolin as filler; its tensile strength is 19MPa, elongation at break is 443%, hardness is Shao A68, water absorption is 2.47%, and maximum thermal decomposition temperature is 359°C.

Embodiment 2

[0034] A kind of preparation method taking modified kaolin as the waterborne polyurethane coating of filler, comprises the following steps:

[0035] (1) Disperse 60 g of uncalcined kaolin and 0.9 g of bis(dioctylpyrophosphate acyloxy)ethylene titanate in 120 ml of absolute ethanol; grind for 1 h at a ball mill speed of 200 r / min, Recover absolute ethanol and dry in an oven at 50°C for 24 hours to obtain hydrophilic modified kaolin.

[0036] (2) Mix 82g of polyurethane emulsion, 18g of hydrophilic modified kaolin, 0.5g of water-based silicone defoamer and 1g of non-ionic water-based polyurethane thickener; ball mill and disperse for 1.5h under the condition of planetary ball mill speed 200r / min to obtain improved Water-based polyurethane coating with non-toxic kaolin as filler; its tensile strength is 20.7MPa, elongation at break is 448%, hardness is Shore A75, water absorption is 1.64%, and maximum thermal decomposition temperature is 371°C.

Embodiment 3

[0038] A kind of preparation method taking modified kaolin as the waterborne polyurethane coating of filler, comprises the following steps:

[0039] (1) Disperse 60 g of uncalcined kaolin and 0.9 g of bis(dioctylpyrophosphate acyloxy)ethylene titanate in 120 ml of absolute ethanol; grind for 1 h at a ball mill speed of 200 r / min, Recover absolute ethanol and dry in an oven at 50°C for 24 hours to obtain hydrophilic modified kaolin. .

[0040] (2) Mix 78g of polyurethane emulsion, 22g of hydrophilic modified kaolin, 0.5g of water-based silicone defoamer and 0.5g of non-ionic water-based polyurethane thickener; ball mill and disperse for 2h under the condition of planetary ball mill speed 200r / min to obtain improved Waterborne polyurethane coating with non-toxic kaolin as filler; its tensile strength is 24MPa, elongation at break is 420%, hardness is Shore A82, water absorption is 1.31%, and maximum thermal decomposition temperature is 379°C.

[0041] Titanate-modified kaolin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com