Application of self-repair material in 3D printing

A self-healing material and 3D printing technology, applied in the field of 3D printing, can solve problems affecting product life, waste, and functional impact, and achieve the effects of increasing service life, improving utilization, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0139] (1) Calculated according to the mass fraction, take 50 parts of polysiloxane A, dissolve in 50 parts of dichloromethane, take 50 parts of polysiloxane B, dissolve in 50 parts of dichloromethane, and dissolve the polysiloxane at 25 °C Mix the solutions of siloxane A and polysiloxane B, and stir for 2 hours at 25°C under mechanical stirring at 1000rmp / min to obtain the pre-printed material;

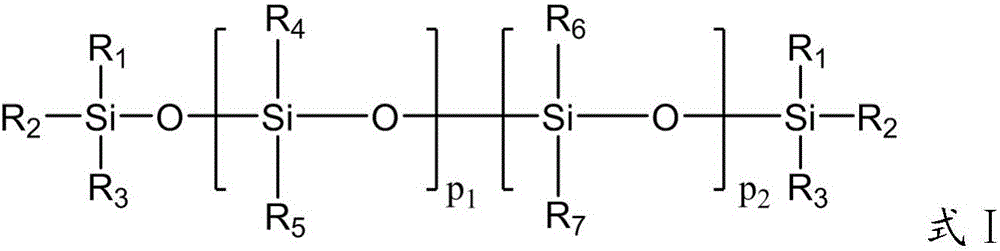

[0140] The structural formula of polysiloxane is shown in formula I,

[0141] Among them, R 1 ~R 6 is methyl;

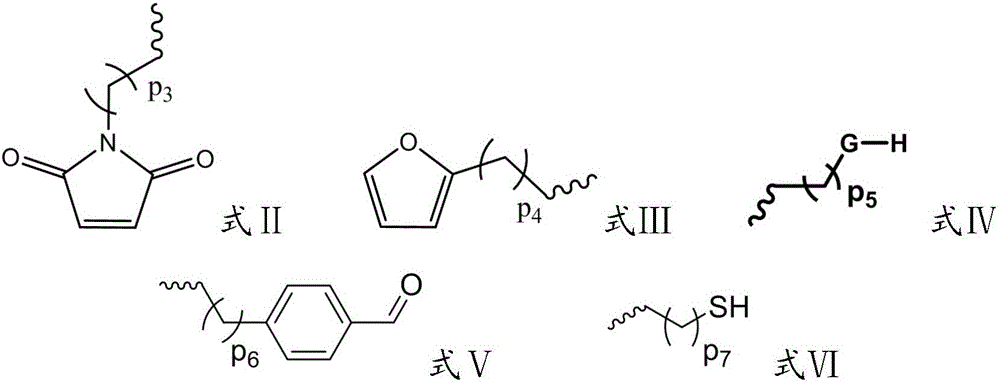

[0142] Polysiloxane A, R 7 is formula Ⅱ, where, p 1 equal to p 2 , is a value between 80 and 100, p 3 The value of is 1;

[0143] Polysiloxane B, R 7 is formula Ⅲ, among them, p 1 equal to p 2 , is a value between 80 and 100, p 4 The value of is 1;

[0144] (2) Heat the pre-printed material obtained in (1) in an oil bath at a rate of 10°C / min, raise the temperature to 75°C, and react for 12h under mechanical stirring at 1000rmp / min; the reaction is over Finally...

Embodiment 2

[0148] (1) Calculated according to the mass fraction, take 50 parts of polysiloxane A, dissolve in 50 parts of dichloromethane, take 50 parts of polysiloxane B, dissolve in 50 parts of dichloromethane, and dissolve the polysiloxane at 25 °C Mix the solutions of siloxane A and polysiloxane B, and stir for 2 hours at 25°C under mechanical stirring at 1000rmp / min to obtain the pre-printed material;

[0149] The structural formula of polysiloxane is shown in formula I,

[0150] Among them, R 2 ~R 7 is methyl;

[0151] Polysiloxane A, R 1 is formula Ⅳ, among them, p 1 equal to p 2 , is a value between 80 and 100, p 5 The value of is 3, G is -NH-;

[0152] Polysiloxane B, R 1 is formula Ⅴ, among them, p 1 equal to p 2 , is a value between 80 and 100, p 6 The value of is 1;

[0153] (2) Heat the pre-printed material obtained in (1) in an oil bath at a rate of 10°C / min, raise the temperature to 75°C, and react for 6 hours under mechanical stirring at 1000rmp / min; Heating ...

Embodiment 3

[0157] (1) Calculated according to the mass fraction, take 50 parts of polysiloxane A, dissolve in 50 parts of tetrahydrofuran, take 50 parts of polysiloxane B, dissolve in 50 parts of tetrahydrofuran, and dissolve polysiloxane A at 25°C Mix with the solution of polysiloxane B, and stir for 2 hours at 25°C under mechanical stirring at 1000rmp / min. get pre-printed material;

[0158] The structural formula of polysiloxane is shown in formula I,

[0159] Polysiloxane A, R2 ~R 7 is methyl, R 1 is the formula Ⅵ, p 7 is 3, p 1 equal to p 2 , is a value between 80 and 100;

[0160] Polysiloxane B, R 1 ~R 6 is methyl, R 7 is the formula Ⅵ, p 7 is 3, p 1 equal to p 2 , is a value between 80 and 100;

[0161] (2) To the preprinted material obtained in (1), add 100 parts of H 2 o 2 , at 25°C, reacted for 6h under mechanical stirring at 1000rmp / min. Then heat at a rate of 10°C / min, raise the temperature to 50°C, and react for 6h under mechanical stirring at 1000rmp / min; 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com