High-temperature-aging-resistant rubber

A technology of high temperature resistance and rubber, applied in the field of materials, can solve the problems of poor high temperature resistance and aging resistance, high cost, limited application scope and service life, etc., to achieve superior high temperature resistance and aging resistance, increase high temperature resistance and The effect of aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

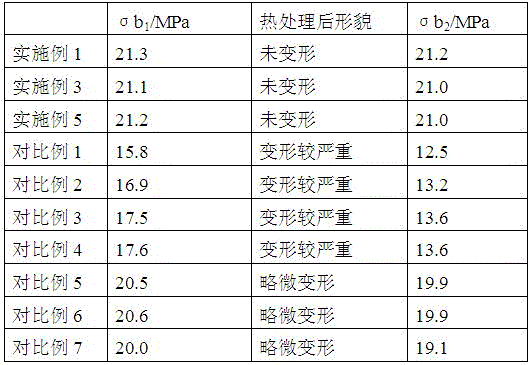

Examples

Embodiment 1

[0014] A high-temperature aging-resistant rubber, according to parts by weight, comprising 15 parts of natural rubber, 30 parts of chloroprene rubber, 40 parts of nitrile rubber, 13 parts of modification additives, 6 parts of zinc oxide, 4 parts of stearic acid, 6 parts of carbon black, 3 parts of mica powder, 2 parts of diisopropyl xanthate disulfide, 2 parts of microcrystalline paraffin, 1.5 parts of sulfur, 4 parts of 2,2'-thiobis ethanol, 3 parts of epoxy fatty acid Polyol ester, 3 parts of rosin lauryl alcohol ester; the modification auxiliary agent is 6 parts of 2-heptadecyl-N-aminoethylimidazoline propylene oxide, 4 parts of polybenzimidazole benzphenanthroline and 3 parts polyquinoline.

[0015] It has been verified that the high-temperature aging-resistant rubber obtained in this embodiment has an aging resistance of 2.5 times in summer.

Embodiment 2

[0017] A high-temperature aging-resistant rubber, comprising 8 parts of natural rubber, 45 parts of chloroprene rubber, 23 parts of nitrile rubber, 8 parts of modification additives, 8 parts of zinc oxide, 3 parts of stearic acid, 9 parts of carbon black, 2 parts of mica powder, 3 parts of diisopropyl xanthate disulfide, 1 part of microcrystalline paraffin, 3 parts of sulfur, 2 parts of 2,2'-thiobis-ethanol, 5 parts of epoxy fatty acid Polyol ester, 1 part of rosin lauryl alcohol ester; the modification auxiliary agent is 4 parts of 2-heptadecyl-N-aminoethyl imidazoline propylene oxide, 3 parts of polybenzimidazole benzphenanthroline and 1 part polyquinoline.

[0018] It has been verified that the high-temperature aging-resistant rubber obtained in this embodiment has an aging resistance of 2.1 times in summer.

Embodiment 3

[0020] A high-temperature aging-resistant rubber, according to parts by weight, including 23 parts of natural rubber, 12 parts of chloroprene rubber, 58 parts of nitrile rubber, 17 parts of modification additives, 4 parts of zinc oxide, 6 parts of stearic acid, 4 parts of carbon black, 4 parts of mica powder, 1 part of diisopropyl xanthate disulfide, 3 parts of microcrystalline paraffin, 0.5 parts of sulfur, 5 parts of 2,2'-thiobis-ethanol, 3 parts of epoxy fatty acid Polyol ester, 3 parts of rosin lauryl alcohol ester; the modification auxiliary agent is 7 parts of 2-heptadecyl-N-aminoethyl imidazoline propylene oxide, 6 parts of polybenzimidazole benzphenanthroline and 4 parts polyquinoline.

[0021] It has been verified that the high-temperature aging-resistant rubber obtained in this embodiment has an aging resistance of 2.2 times in summer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com