Preparation method of highly hydrophobic carbon fluoride nanotube/polyimide composite material

A technology of fluorinated carbon nanotubes and hydrofluorocarbons is applied in the field of preparation of polyimide composite materials, which can solve problems such as limitations and achieve the effects of improving hydrophobic properties and improving mechanics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0040] Embodiment 1: This embodiment is a preparation method of a highly hydrophobic fluorinated carbon nanotube / polyimide composite material, which is completed in the following steps:

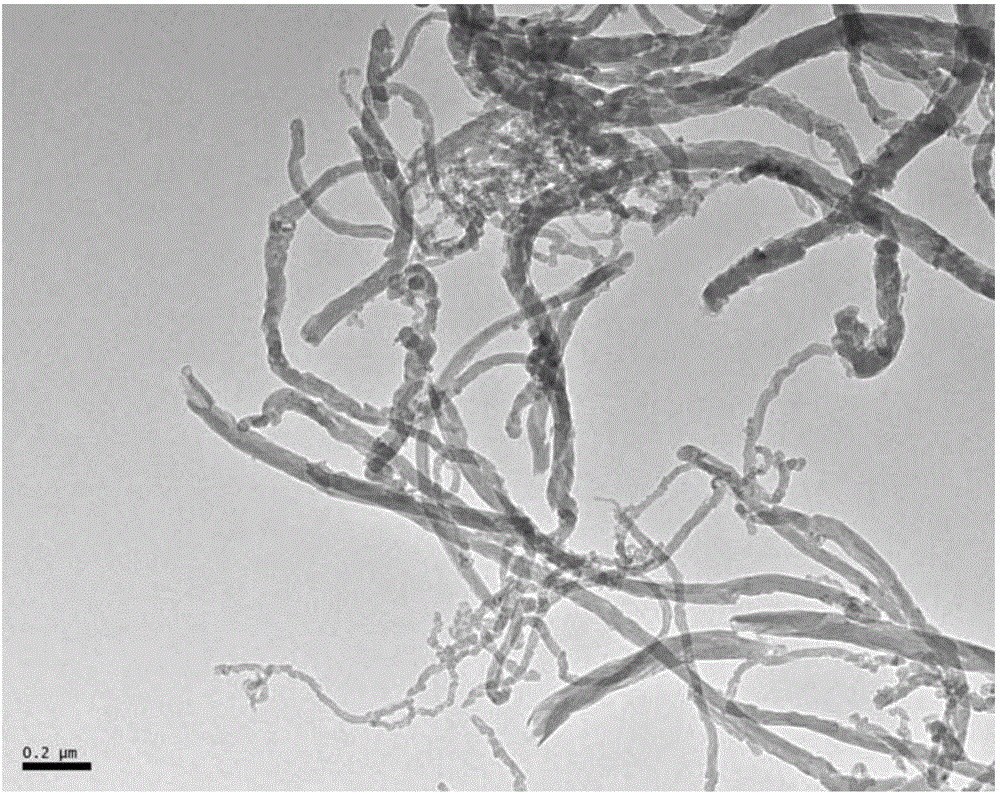

[0041] 1. Preparation of fluorinated carbon nanotubes:

[0042] ①, the multi-walled carbon nanotubes are placed in an airtight container;

[0043] ②. Vacuumize the airtight container until the pressure in the airtight container drops below 1Pa; then inject argon into the airtight container until the pressure in the airtight container rises to 10 5 Pa;

[0044] ③. Repeat step 1 ② 3 to 5 times;

[0045] ④. Put the mixed gas of argon and fluorine into the airtight container until the pressure in the airtight container rises to 0.5atm~1atm. The heating rate is raised from room temperature to 150°C to 300°C, and then kept at a pressure of 0.5atm to 1atm and a temperature of 150°C to 300°C for 1h to 3h to obtain fluorinated carbon nanotubes;

specific Embodiment approach 2

[0069] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step 1.4, pass the mixed gas of argon and fluorine gas into the airtight container until the pressure in the airtight container rises to 1 atm, and then the pressure is The temperature was raised from room temperature to 250° C. at a rate of 4° C. / min at 1 atm, and then kept at a pressure of 1 atm and a temperature of 250° C. for 2 hours to obtain fluorinated carbon nanotubes. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

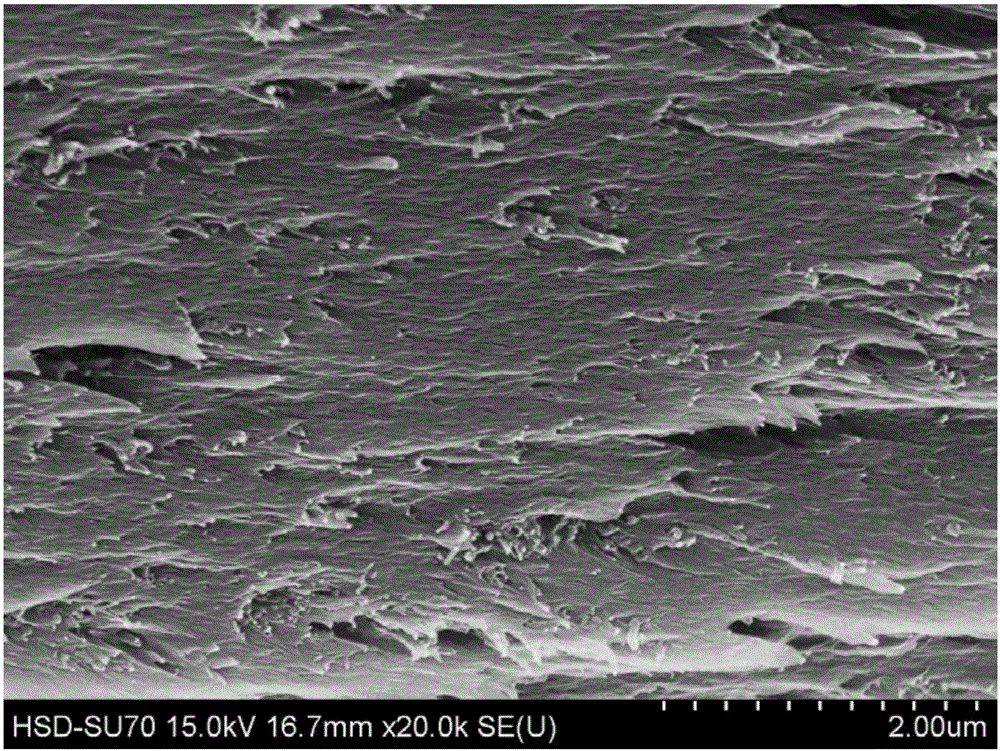

[0070] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step 2 ①, the fluorinated carbon nanotubes obtained in step 1 are added in dimethylacetamide, and then the stirring speed is Stirring and reacting at 100 r / min for 2 hours, and then sonicating at an ultrasonic power of 300 W for 12 hours to obtain a dispersion of fluorinated carbon nanotubes with a mass fraction of 0.5% of fluorinated carbon nanotubes. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com