Desulfurization wastewater concentration, evaporation, crystallization and salt separation process

A technology for concentrating evaporation and desulfurization wastewater, which is applied in centrifugal separation of water/sewage treatment, alkali metal sulfite/sulfate purification, water pollutants, etc. Slow, high concentration of calcium and magnesium, to achieve the effect of not easy to block the pipe, improve efficiency and productivity, and high concentration of calcium and magnesium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

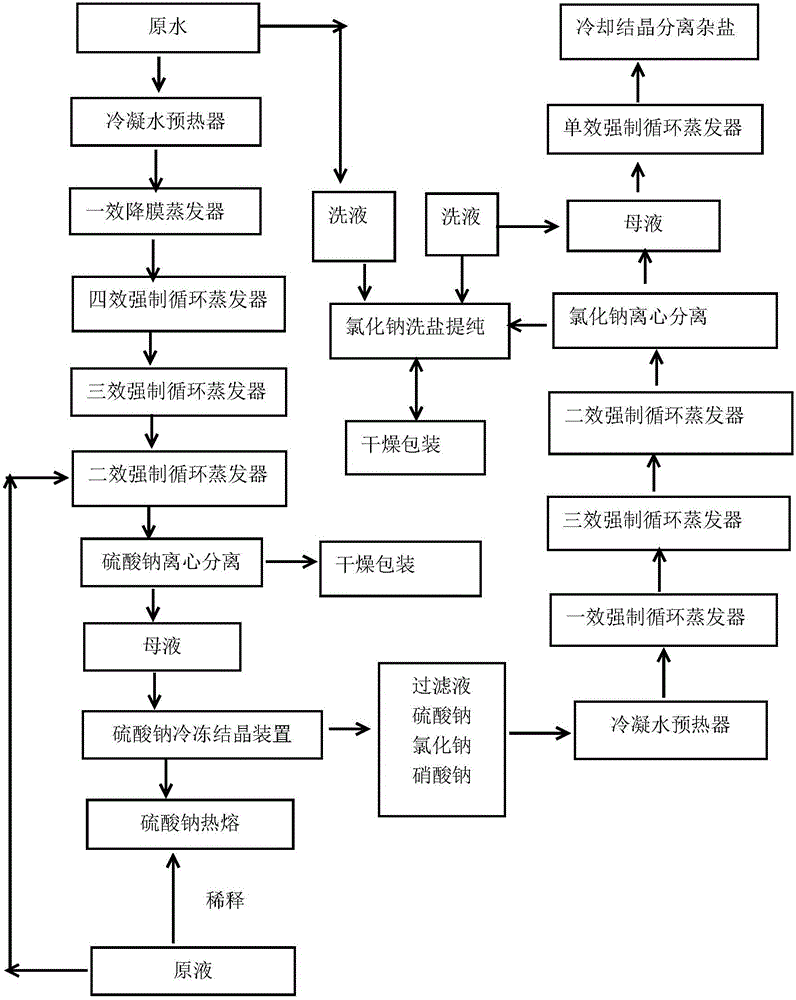

[0035] refer to figure 1 As shown, this embodiment discloses a desulfurization wastewater concentration evaporation, crystallization, and salt separation process, including the following steps:

[0036] (1) The raw water enters the condensed water preheater through the feed pump, and is preheated to raise the temperature.

[0037] (2) After preheating and heating up, it enters the separator of the first-effect falling film evaporator, and the first-effect circulating pump sends the material in the first-effect separator to the top of the first-effect heater to form a film-like downward flow. Heat exchange outside the tube, evaporating water to increase the concentration.

[0038] (3) The material coming out of the one-effect falling film evaporator enters the four-effect forced circulation evaporator through the one-effect circulating pump, and in the separator of the four-effect forced circulation evaporator, the four-effect forced circulation evaporator The circulation pum...

Embodiment 2

[0050] In Example 2, taking the steps of Example 1 as an example, the desulfurization wastewater is divided into three stages, and sodium sulfate, sodium chloride and miscellaneous salts are separated respectively.

[0051] 1. 80m 3 / hr sodium sulfate evaporation process

[0052] (1) Materials:

[0053] The raw water enters the condensate water preheater through the feed pump, and enters the first-effect separator after preheating. exchange to achieve the purpose of evaporating part of the water and increasing the concentration.

[0054] The four-effect material is transferred to the separator through the one-effect circulation pump, and the material is conveyed by the forced circulation pump to exchange heat through the heat exchanger to achieve the purpose of evaporating part of the water and increasing the concentration.

[0055] The three-effect material is pumped into the three-effect separator through the four-effect material transfer pump, and the material is conveye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com