Preparation method and application of graphene hollow carbon nanocages

A graphene and hollow carbon technology, applied in the field of preparation of graphene hollow carbon nano-cage materials, can solve the problems of high price, high energy consumption, complicated operation and the like, and achieve the effects of simple method, high efficiency and reduced preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

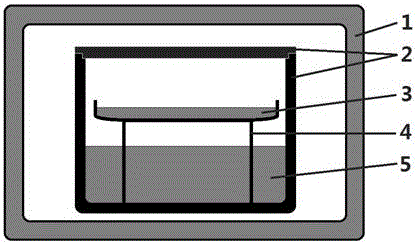

[0041] Put bagasse, a solid-phase carbon source, in an oven at 80°C for 12 hours, and then crush it with a pulverizer. The average particle size after crushing is 2 cm; place the catalyst precursor nickel acetate in a ball mill for ball milling, and the average particle size after ball milling is 2 μm; get 20g of the gained bagasse particles and place them on the lower layer of the graphite crucible, get 7g of the gained nickel acetate particles and place them on the upper layer of the graphite crucible to form an upper and lower layer structure, and cover them with a graphite cover, place them in a box-type resistance furnace for heat treatment (such as figure 1 shown), the heat treatment temperature is 700°C, the heating time is 20min, and the heating rate is 10°C / min; finally, the upper layer product obtained is collected, soaked in 10mol / L hydrochloric acid for 2h, washed with distilled water, filtered, After drying, the graphene hollow nanocages are obtained.

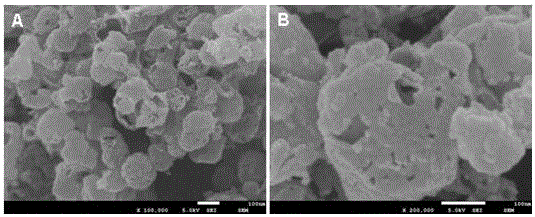

[0042] The...

Embodiment 2

[0044] Put bagasse, a solid-phase carbon source, in an oven at 80°C for 12 hours, and then crush it with a pulverizer. The average particle size after crushing is 2 cm; place the catalyst precursor nickel acetate in a ball mill for ball milling, and the average particle size after ball milling is 0.5 μm; get 20g of the gained bagasse particles and place them on the lower layer of the graphite crucible, get 7g of the gained nickel acetate particles and place them on the upper layer of the graphite crucible to form an upper and lower layer structure, and cover them with a graphite cover, place them in a box-type resistance furnace for heat treatment (such as figure 1 shown), the heat treatment temperature is 700°C, the heating time is 20min, and the heating rate is 10°C / min; finally, the upper layer product obtained is collected, soaked in 10mol / L hydrochloric acid for 2h, washed with distilled water, filtered, After drying, the graphene hollow nanocages are obtained.

[0045] T...

Embodiment 3

[0047] Put bagasse, a solid-phase carbon source, in an oven at 80°C for 12 hours, and then crush it with a pulverizer. The average particle size after crushing is 2 cm; place the catalyst precursor nickel acetate in a ball mill for ball milling, and the average particle size after ball milling is 5 μm; get 20g of the gained bagasse particles and place them on the lower layer of the graphite crucible, get 7g of the gained nickel acetate particles and place them on the upper layer of the graphite crucible to form an upper and lower layer structure, and cover them with a graphite cover, place them in a box-type resistance furnace for heat treatment (such as figure 1 shown), the heat treatment temperature is 700°C, the heating time is 20min, and the heating rate is 10°C / min; finally, the upper layer product obtained is collected, soaked in 10mol / L hydrochloric acid for 2h, washed with distilled water, filtered, After drying, the graphene hollow nanocages are obtained.

[0048] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com