A kind of portable chlorine dioxide generator and using method thereof

A chlorine dioxide and generator technology, applied in chlorine dioxide, chlorine oxide, chemistry, etc., can solve the problems of expensive liquefaction treatment, explosive decomposition, etc., and achieve the effect of wide spraying range, good effect and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

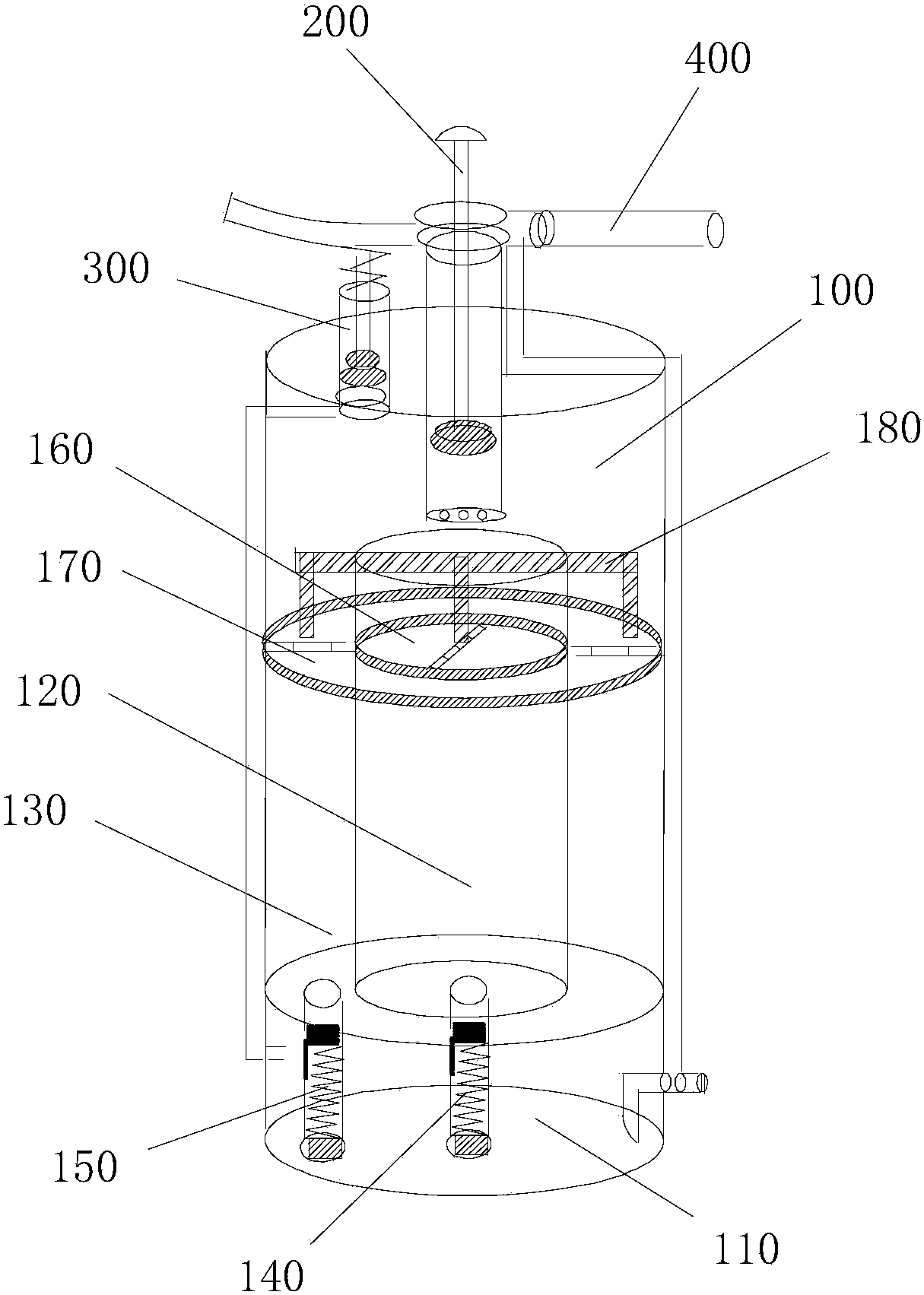

Embodiment 1

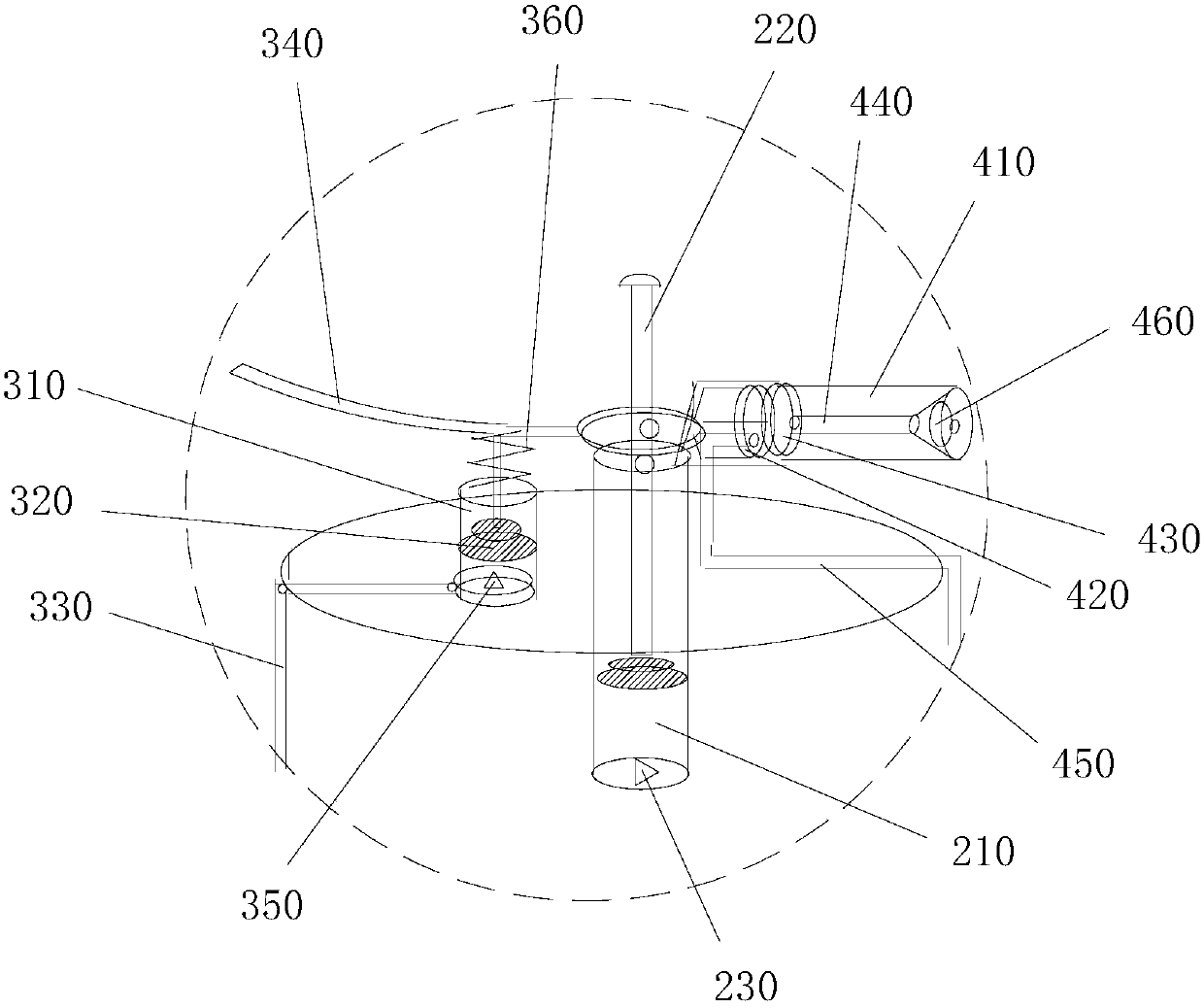

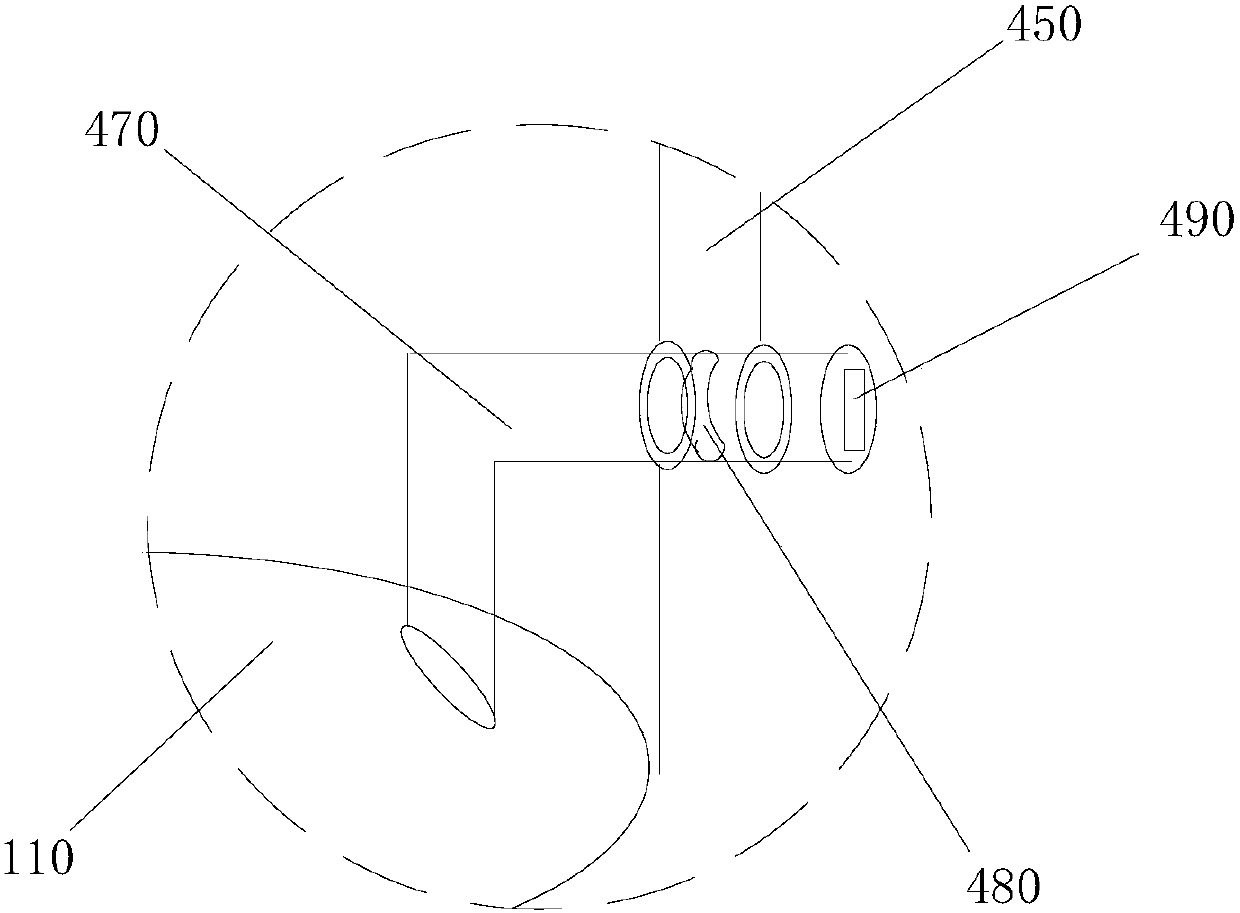

[0074] At room temperature, prepare 100ml of a nearly saturated ethylenediaminetetraacetic acid disodium aqueous solution with a mass fraction of 10%, and pass the gas prepared by the reaction method of sodium chlorite and hydrochloric acid into the EDTA aqueous solution for 30 minutes, then place the absorption solution in the first A storage room 120, another preparation of 0.05mol / L Fe 2 (SO4) 3 Put 100ml of aqueous solution in the second storage chamber 130, manually stretch and push the first one-way piston with handle for more than 220 times, gently shake the sterilizer, and then repeatedly press the atomization pressure head switch 340 in a short period of time. The disinfectant is sprayed on the surface of the object to be treated in a mist liquid state to achieve disinfection.

Embodiment 2

[0076] At room temperature, prepare 100ml of disodium ethylenediaminetetraacetic acid aqueous solution with a mass fraction of 8%, and pass the gas prepared by the reaction method of sodium chlorite and hydrochloric acid into the EDTA aqueous solution for 30 minutes, and then place the absorption solution in the first reserve Room 120, prepare another 0.1mol / L ZnSO 4 Put 100ml of aqueous solution in the second storage chamber 130, manually stretch and push the first one-way piston with handle for more than 220 times, gently shake the sterilizer, and then repeatedly press the atomization pressure head switch 340 in a short period of time. The disinfectant is sprayed on the surface of the object to be treated in a mist liquid state to achieve disinfection.

Embodiment 3

[0078] At room temperature, prepare 100ml of a nearly saturated ethylenediaminetetraacetic acid disodium aqueous solution with a mass fraction of 10%, and pass the gas prepared by the reaction method of sodium chlorite and hydrochloric acid into the EDTA aqueous solution for 30 minutes, then place the absorption solution in the first A reserve chamber 120, another preparation of 0.1mol / L Fe 2 (SO4) 3 Put 100ml of aqueous solution in the second storage chamber 130, manually repeatedly stretch and push the first one-way piston with handle for more than 220 times, gently shake the sterilizer, and press the hand-pressed atomization head switch for a period of time (after 20 minutes) 340, that is, the disinfectant is sprayed on the surface of the object to be treated in a mist liquid state to achieve disinfection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com