Box lowering method of box packing machine

A cartoning machine and carton unloading technology, which is applied in the directions of packaging, conveyors, and unstacking of objects, and can solve the problems that the fork plate cannot be inserted accurately and the trays cannot be accurately separated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for unloading a cartoning machine comprises the steps:

[0032] A. Place multiple stacked trays in the tray storage space 5;

[0033] B. The front, rear, left and right four sides of the tray storage space 5 are each provided with at least one fork plate 3, and the two fork plates 3 provided in the front and rear directions are the first group of fork plates 6. The two set of fork plates 3 are the second set of fork plates 7, the first set of fork plates 6 and the second set of fork plates 7 are located under the lowermost tray, supporting multiple stacked trays;

[0034] C. The negative pressure device 8 located under a plurality of trays rises below the outer bottom surface of the lowest tray, and performs negative pressure adsorption on the bottom surface of the tray. At the same time, the first set of fork plates 6 move away from the tray Move in the direction and let go of the tray, from two sets of fork plates 3 supporting the tray to a set of fork plate...

Embodiment 2

[0041] A method for unloading a cartoning machine comprises the steps:

[0042] A. Place multiple stacked trays in the tray storage space 5;

[0043] B. The front, rear, left and right four sides of the tray storage space 5 are each provided with at least one fork plate 3, and the two fork plates 3 provided in the front and rear directions are the first group of fork plates 6. The two set of fork plates 3 are the second set of fork plates 7, the first set of fork plates 6 and the second set of fork plates 7 are located under the lowermost tray, supporting multiple stacked trays;

[0044] C. The negative pressure device 8 located under a plurality of trays rises below the outer bottom surface of the lowest tray, and performs negative pressure adsorption on the bottom surface of the tray. At the same time, the first set of fork plates 6 move away from the tray Move in the direction and let go of the tray, from two sets of fork plates 3 supporting the tray to a set of fork plate...

Embodiment 3

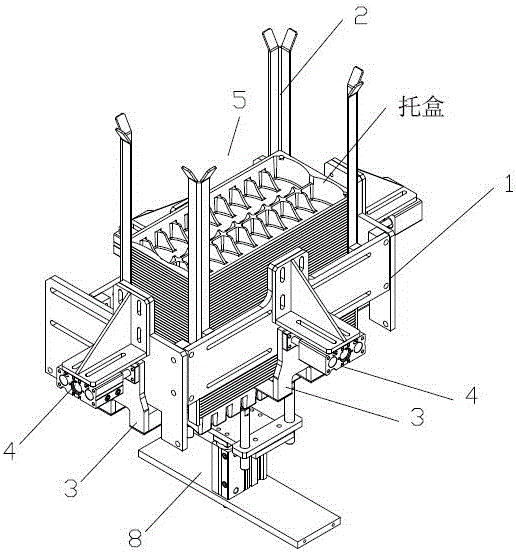

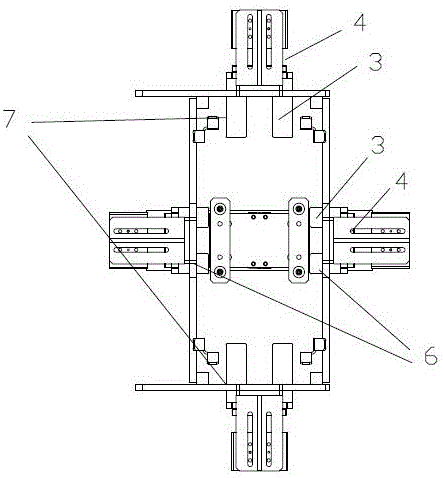

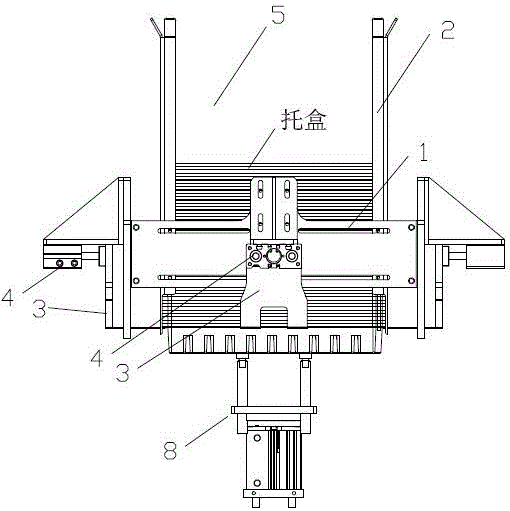

[0054] The equipment that realizes the method for embodiment 1 and embodiment 2 can be the unboxing mechanism of following product cartoning machine: it comprises fixed frame 1, and a plurality of guard plates 2 that fix the position of tray box are installed in described fixed frame 1, so A fork plate 3 is arranged between the adjacent guard plates 2, the fork plate 3 is connected to the fork plate cylinder 4, a negative pressure device 8 is arranged below the guard plate 2, and the guard plate 2 surrounds to form a tray for placing the tray. The tray storage space 5 is provided with at least one fork plate 3 in each of the front, rear, left and right directions of the tray storage space 5, and the two fork plates 3 arranged in the front and rear directions are the first group The fork plates 6 and the two fork plates 3 arranged in the left and right directions are the second set of fork plates 7 , and the first set of fork plates 6 and the second set of fork plates 7 alternat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com