Laser forming method for lightweight structural plate

A laser forming and lightweight technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low forming efficiency, long forming cycle, long aging forming cycle, etc., and achieve high forming efficiency and high forming speed. , the effect of short forming cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0034] A specific embodiment of the present invention is as follows:

[0035] refer to image 3 , Laser forming of 5A06 aluminum alloy sheet with skin geometric size 400×400.

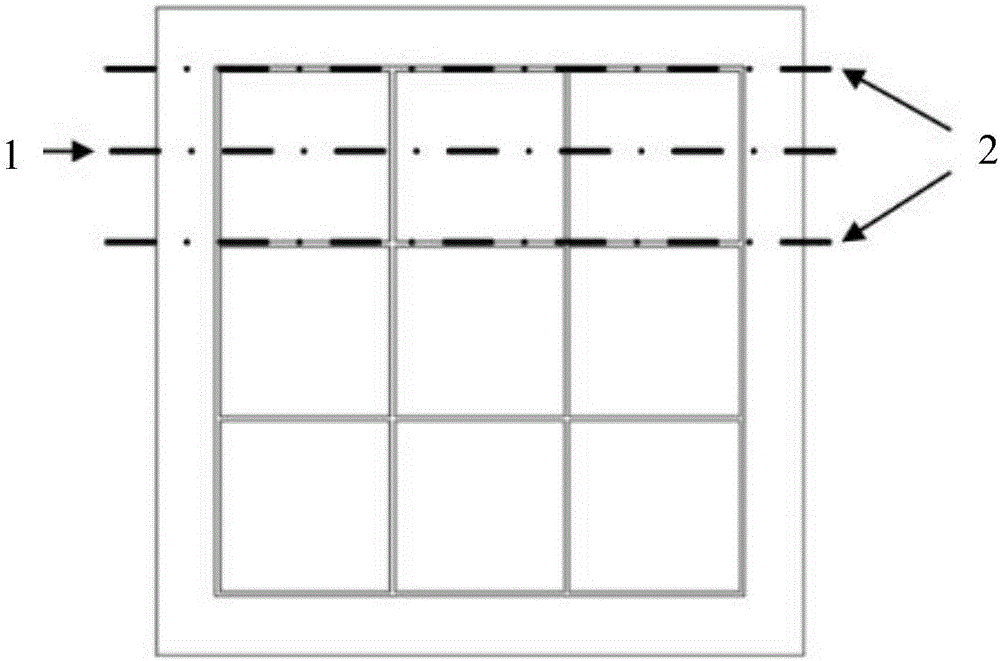

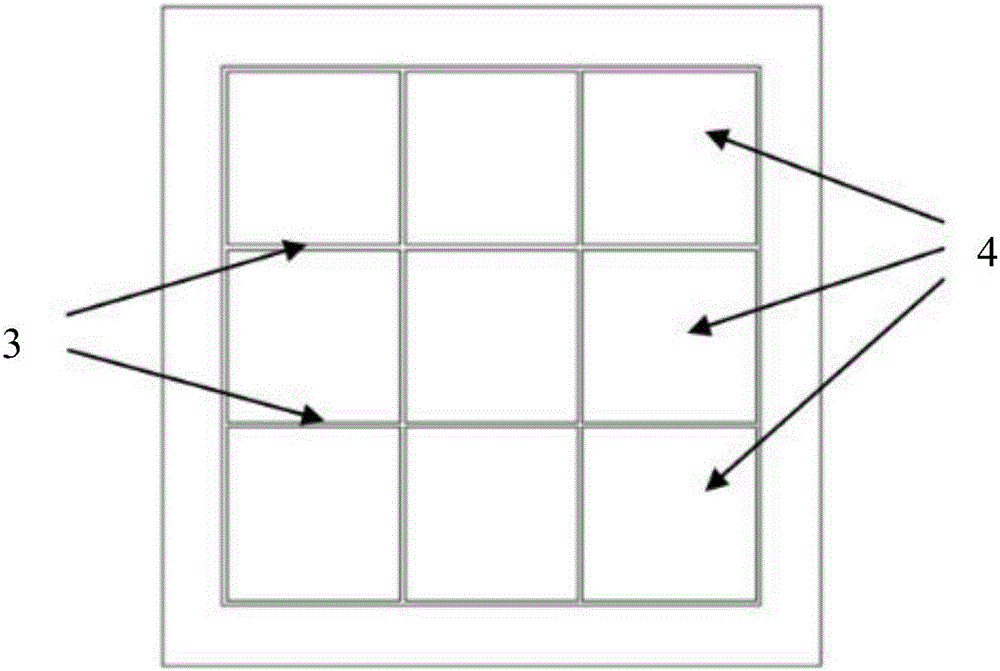

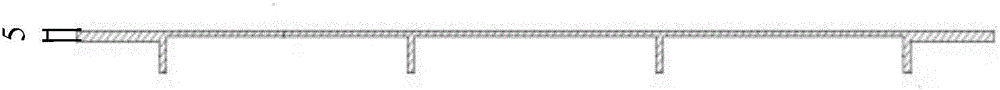

[0036] After the surface of the skin is cleaned, the whole is coated with a thin layer of water-based graphite or ethanol graphite, and the plate is clamped with a pressing block to hold the 5mm thick parts of the middle part of the plate and fixed on the workbench. Select the scanning position, and the selected scanning position is: the position 104mm away from the free end of the grid part 4 of the plate.

[0037] The forming parameters of the selected laser are: laser power 1100W, scanning speed 20mm / s, spot diameter 12mm, scan the plate from one end of the scanning line to the other end, and scan twice in total. After the first scan, the plate was cooled to room temperature before the second scan. The forming result of the scanned plate is extracted using a 3D scanner.

[0038] Through experimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com