Arc alignment device for mold and arc alignment method

A crystallizer and centering device technology, which is applied in the field of maintenance of continuous casting machines, can solve problems such as loss of alignment meaning, long working hours, and heavy workload, so as to improve the operation rate of casting machines, save maintenance time, and be easy to operate line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

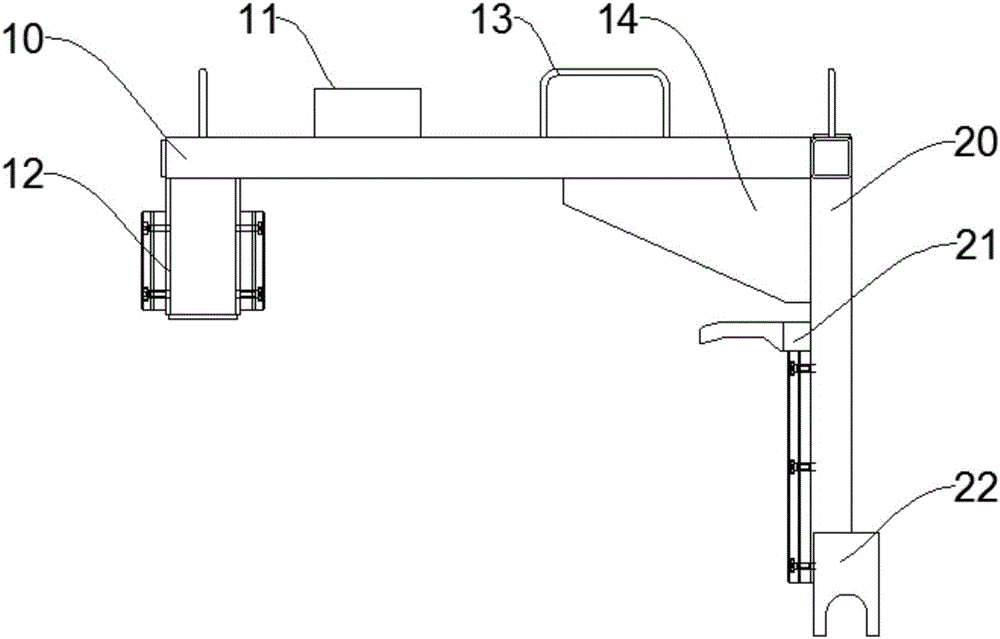

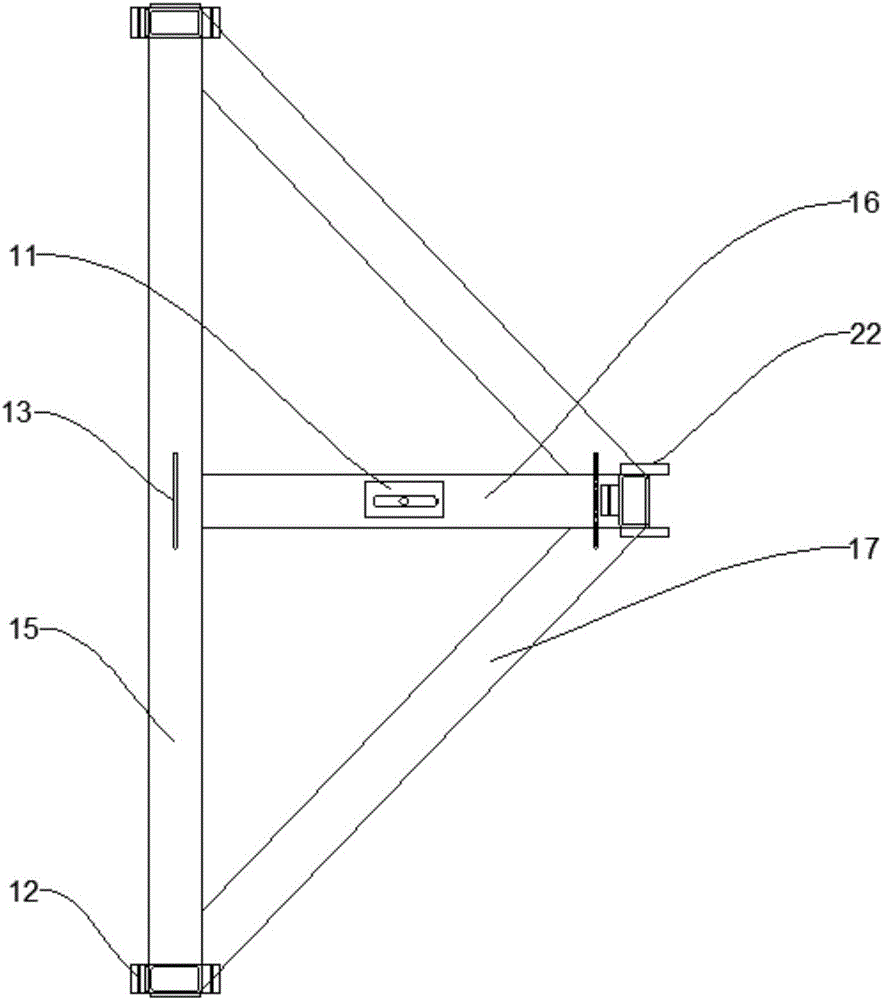

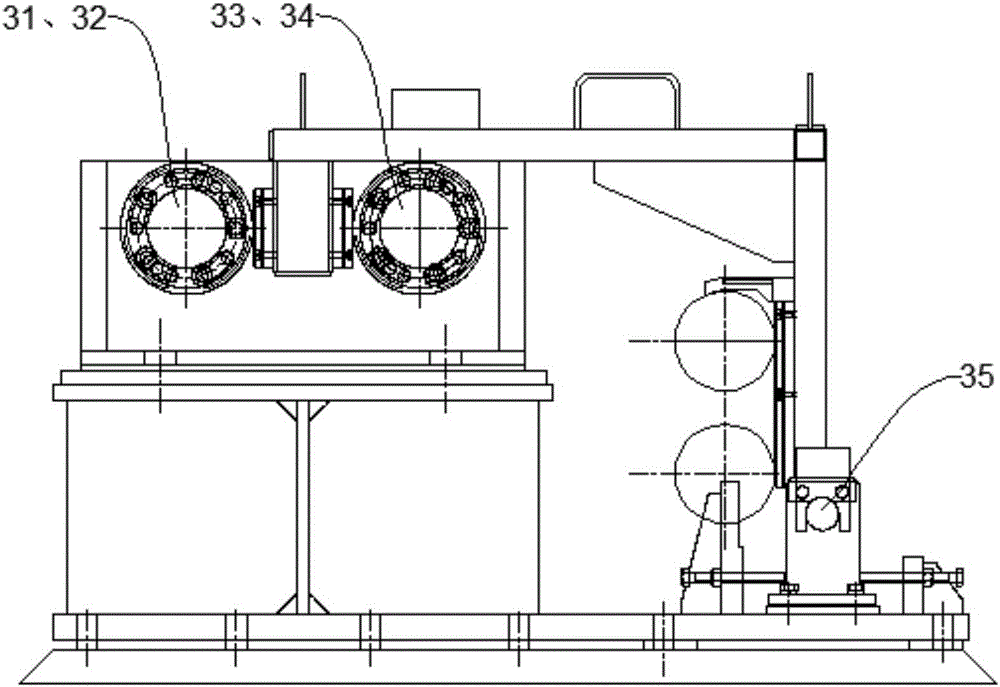

[0057] In order to describe the present invention in detail, the present invention is described in detail next: please refer to Figure 1 to Figure 6, a crystallizer arc alignment device, including a support frame, the support frame includes a first beam 15, a second beam 16 and a column 20. The first beam 15 and the second beam 16 are arranged horizontally, and the second beam 16 is located on the perpendicular bisector of the first beam 15 . The column 20 is arranged vertically, and the upper end of the column 20 is fixedly connected with the right end of the second beam 16 . In this embodiment, the supporting frame further includes two reinforcing beams 17 and one reinforcing rib 14 . Two reinforcing beams 17 are arranged symmetrically, wherein, the first end of one reinforcing beam 17 is connected to the upper end of the first beam 15, and the second end is connected to the right end of the second beam 16; the first end of the other reinforcing beam 17 is connected to the...

Embodiment 2

[0072] The difference from Example 1 is that the sequence of steps in the arc alignment method is as follows: 1. Calibrate the offline centering platform, 2. Calibrate the crystallizer vibration guide wheel supporting the guide section, 3. Calibrate the crystallizer, 4. Calibrate the crystallizer Install.

Embodiment 3

[0074] The difference from Example 1 is that the order of the steps in the arc alignment method is as follows: 1. Calibrate the crystallizer vibration guide wheel supporting the guide section, 2. Calibrate the offline centering platform, 3. Calibrate the crystallizer, 4. Crystallizer Install.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com