MVR evaporative combination device for percolate and treating method thereof

A combination of equipment and leachate technology, applied in the direction of evaporation, separation methods, steam pressurized evaporation, etc., can solve problems such as CODCr and chromaticity exceeding the standard, complex components, and concentrates that cannot be solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following clearly and completely describes the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

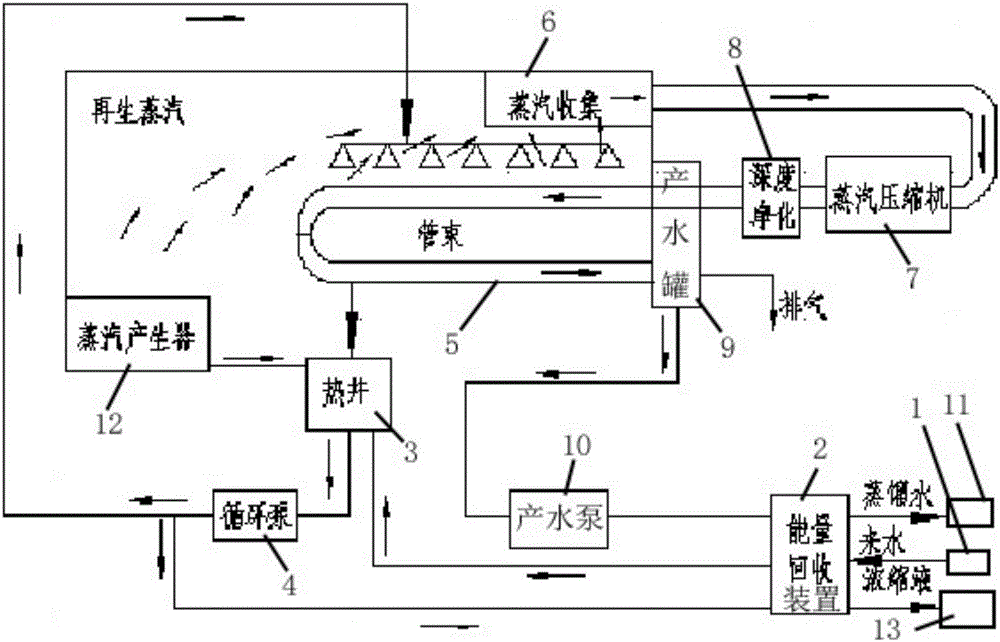

[0032] Such as figure 1 As shown, the embodiment of the present invention provides a combined device for evaporating leachate MVR for treating landfill leachate, including:

[0033] Inlet pump 1, energy recovery device 2, hot well 3, circulation pump 4, heat exchange equipment 5, steam collection equipment 6, steam compressor 7, water production tank 9, water production pump 10, water production tank 11, concentrated water tank 13 , pressure gauges and control devices; among them,

[0034] The energy recovery device is equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com