Laser welding suction nozzle and laser welding gun

A laser welding, consistent technology, applied in the direction of laser welding equipment, welding equipment, welding equipment, etc., can solve the problem of large overall volume of the suction nozzle, achieve the effect of avoiding difficult processing, improving welding efficiency and welding quality, and reducing interference effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

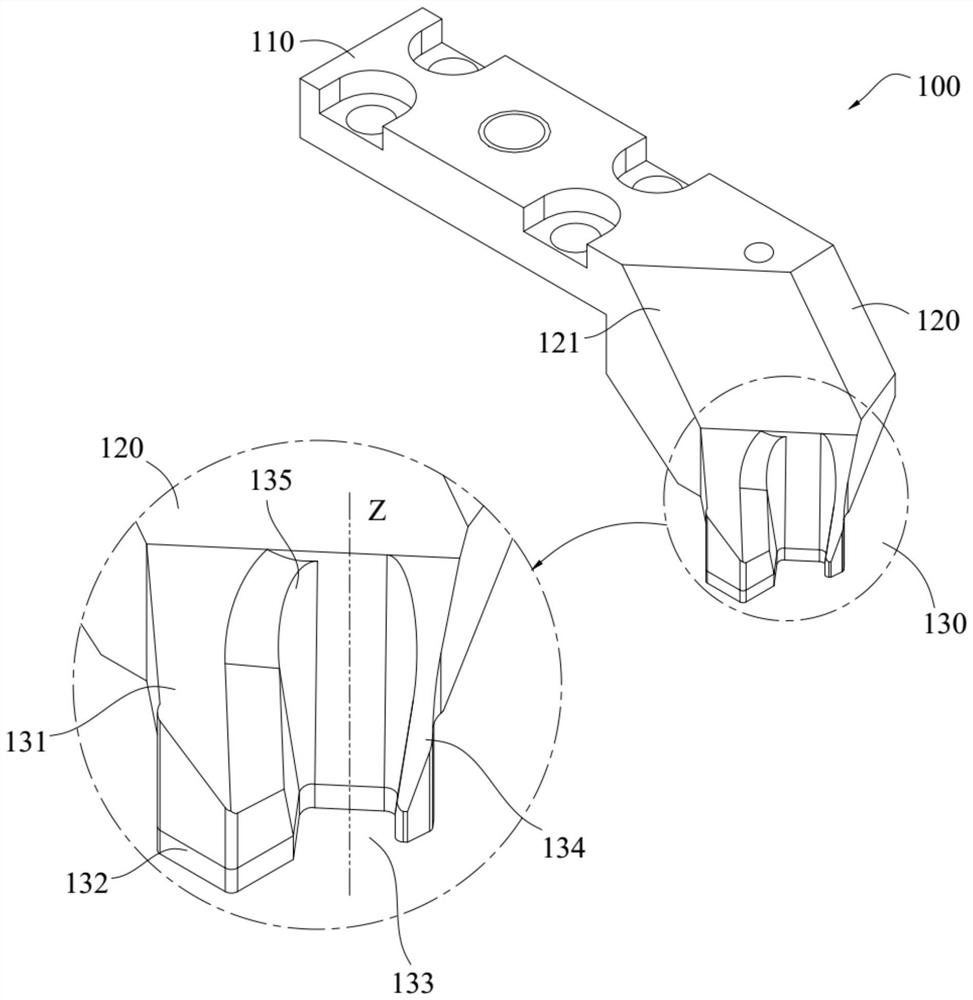

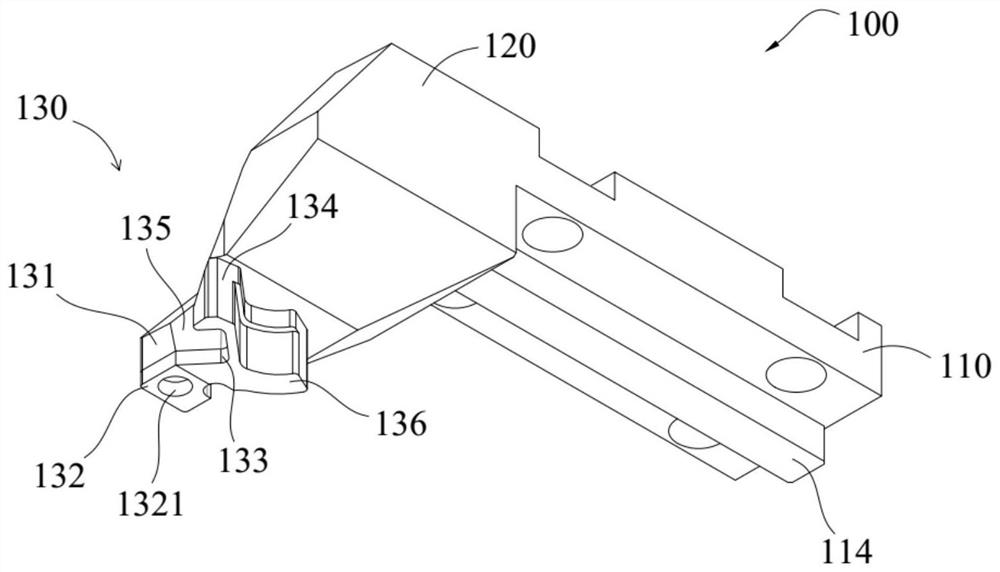

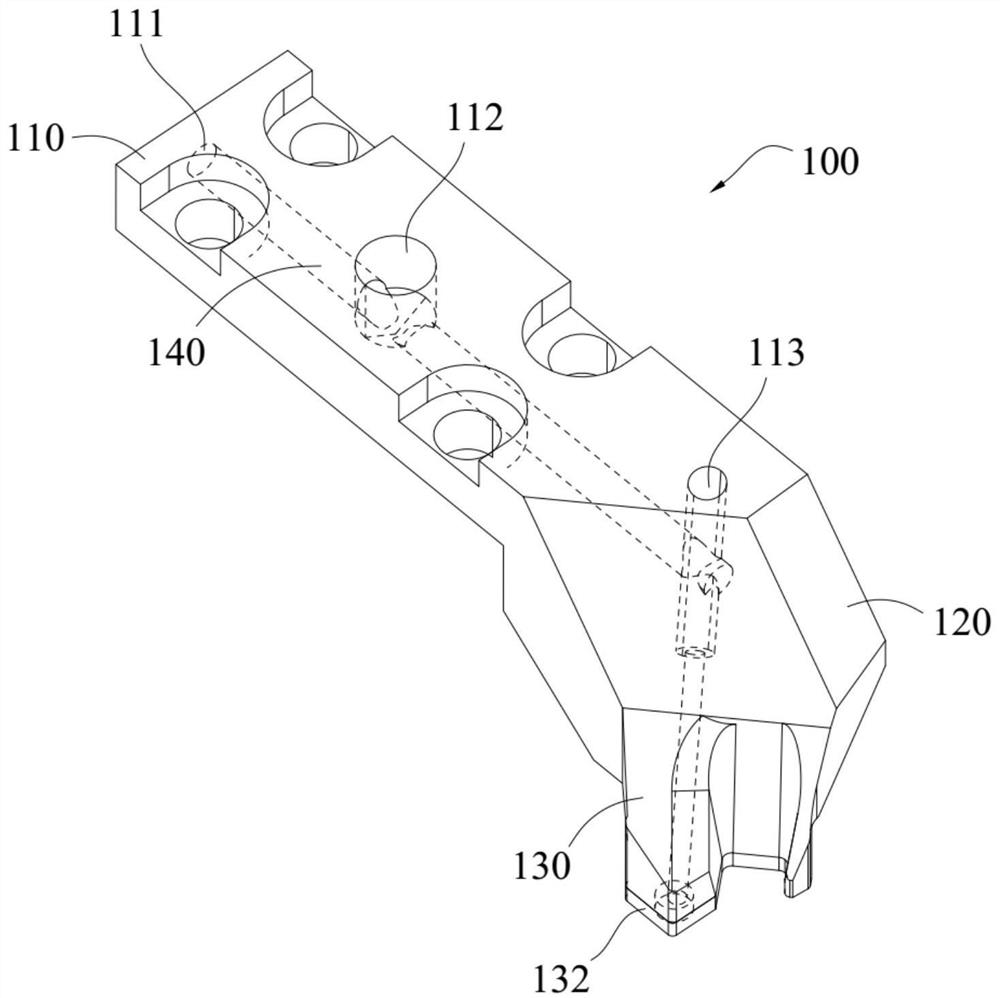

[0057] According to an embodiment of the present invention, a combination of Figure 1 ~ Figure 3 From the illustration, it can be seen that the laser welding nozzle 100 includes:

[0058] Mounting section 110;

[0059] a suspension section 120, which is integrally joined to the installation section 110 at one end of the installation section 110 and extends downward from the installation section 110; and

[0060] an extension section mounted to the bottom of the overhanging section 120;

[0061] Wherein, at least part of the outer periphery of the extension section protrudes from the outside of the overhanging section 120 to form a convex portion 130, and a light-transmitting hole 133 is opened through the upper and lower surfaces of the convex portion 130, and the light-transmitting The hole 133 is open at its outer side to separate the convex portion 130 into a suction block 131 and a pressing block 134 . refer to Figure 22 , during welding, the laser welding suction no...

Embodiment 2

[0074] According to an embodiment of the present invention, a combination of Figure 8 ~ Figure 11 From the illustration, it can be seen that the laser welding nozzle 200 includes:

[0075] Mounting section 210;

[0076]a suspension section 220, which is integrally joined to the installation section 210 at one end of the installation section 210 and extends downward from the installation section 210; and

[0077] an extension section mounted to the bottom of the overhanging section 220;

[0078] Wherein, at least part of the outer periphery of the extension section protrudes from the outside of the overhanging section 220 to form a convex portion 230, and a light-transmitting hole 233 is opened through the upper and lower surfaces of the convex portion 230, and the light-transmitting The hole 233 is opened on its outer side to separate the protruding part 230 into a suction block 231 and a pressing block 234 . During welding, the laser welding suction nozzle 200 sucks the w...

Embodiment 3

[0091] According to an embodiment of the present invention, a combination of Figure 15 ~ Figure 17 As shown, it can be seen that the laser welding nozzle 300 includes:

[0092] Mounting section 310;

[0093] a suspension section 320, which is integrally joined to the installation section 310 at one end of the installation section 310 and extends downward from the installation section 310; and

[0094] an extension section mounted to the bottom of the overhang section 320;

[0095] Wherein, at least part of the outer periphery of the extension section protrudes from the outside of the overhanging section 320 to form a convex portion 330, and a light-transmitting hole 333 is opened through the upper and lower surfaces of the convex portion 330, and the light-transmitting The hole 333 is open at its outer side to separate the protruding portion 330 into a suction block 331 and a pressing block 334 . During welding, the laser welding nozzle 300 sucks the workpiece through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com