Method for preparation of freeze-dried corn flour

A corn flour and freeze-drying technology, which is applied in food drying, food freezing, and the function of food ingredients, etc., can solve the problems of poor color of corn flour, coarse particles, poor taste, and easy agglomeration after brewing, so as to prevent skin lesions, Strong aroma, the effect of alleviating arteriosclerosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

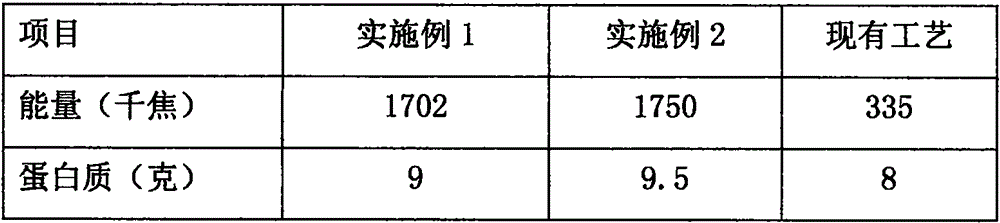

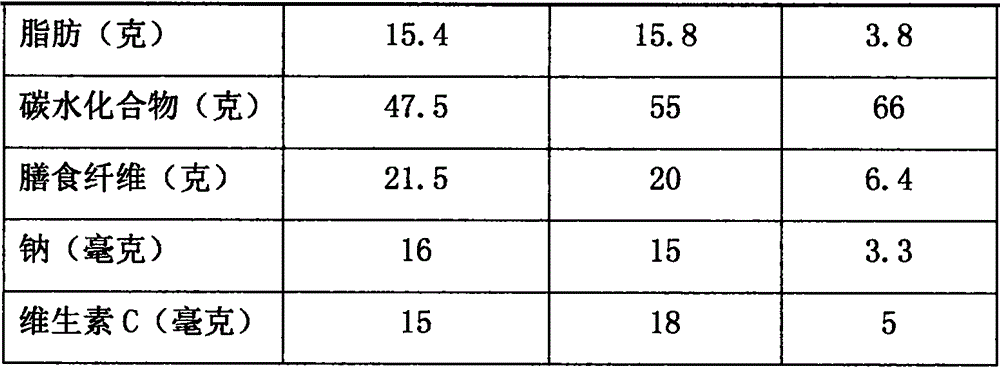

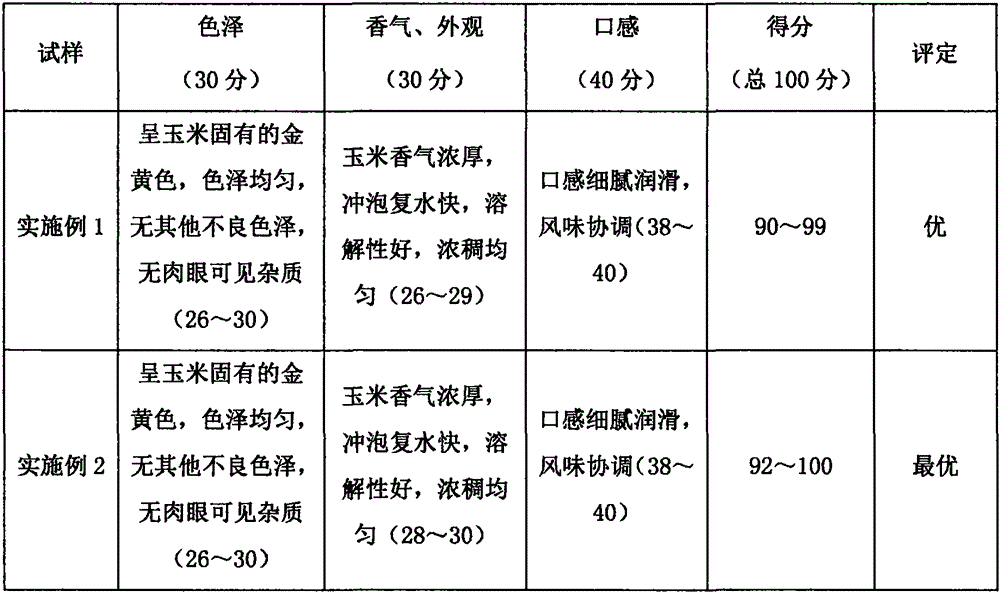

Examples

Embodiment 1

[0029] A preparation method of freeze-dried corn flour, comprising the following steps:

[0030] (1) Raw material acceptance: after passing the acceptance according to the quick-frozen raw material acceptance standards, prepare the raw materials for use on the day according to the process quantity requirements;

[0031] (2) Storage: raw materials are stored in a freezer at a temperature below -18°C;

[0032] (3) Thawing: thaw the raw materials until they soften or thaw them naturally at room temperature until they do not agglomerate;

[0033] (4) Selection: remove impurities and insect pest raw materials other than corn;

[0034] (5) Finishing: Use steam to cook 10kg of raw materials per frame for 30 minutes until they are fully cooked;

[0035] (6) Mixing sugar: using boiling water to dissolve the glucose solution with a concentration of 70%, get the glucose solution and corn by 5% of the paving amount and stir evenly,

[0036] (7) Spreading tray: Weigh the material and sp...

Embodiment 2

[0049] A kind of preparation method of freeze-dried corn flour as described in embodiment 1, wherein step 1), 2), 3), 5), 9) can also adopt following technical scheme:

[0050] (1) Raw material acceptance: after passing the acceptance according to the fresh raw material acceptance standards, prepare the raw materials for use on the day according to the process quantity requirements;

[0051] (2) Storage: Fresh raw materials are stored in a freezer at a temperature below -18°C;

[0052] (3) remove leaf bud and threshing: remove raw material leaf bud, and thresher carries out threshing process;

[0053] (5) Finishing: Use steam to cook 10kg of raw materials per frame for 40 minutes until they are fully cooked;

[0054] (9) Freeze-drying: after the temperature of the material reaches the requirement, put it into the furnace for freeze-drying in time, set the freeze-drying curve; set the heating temperature to 100° C., the vacuum degree to 110 Pa, and the drying time to be 19 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com