Blueberry vinegar beverage product and making method thereof

A production method and blueberry vinegar technology are applied in the field of production technology of blueberry vinegar beverages, which can solve the problems of difficult retention of blueberry active ingredients, and achieve the effects of increasing natural anthocyanin content, reducing oxygen content, and promoting healthy development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: the extraction method of blueberry pigment

[0048] 100kg of rot-free blueberry raw materials are selected, washed, air-dried at 45 to 55° C. to control the water content of the blueberries at 20 to 30%, and the blueberries are mashed and pulped to obtain blueberry pulp. Take 80L of blueberry pulp, add 200L of 50% ethanol solution, adjust the pH value to 4 with 0.1mol / L hydrochloric acid, stir and extract at room temperature for 60h, filter with 2 layers of gauze, repeat twice, combine the filtrates, and the obtained blueberry pulp is for use , the obtained filtrate was concentrated to 1 / 45 of the original volume under reduced pressure below 50°C, adsorbed on LSA-7 macroporous resin, and eluted with a 15BV 45-85% ethanol aqueous solution for gradient elution. The eluate was concentrated to dryness under reduced pressure below 50°C to obtain blueberry pigment.

Embodiment 2

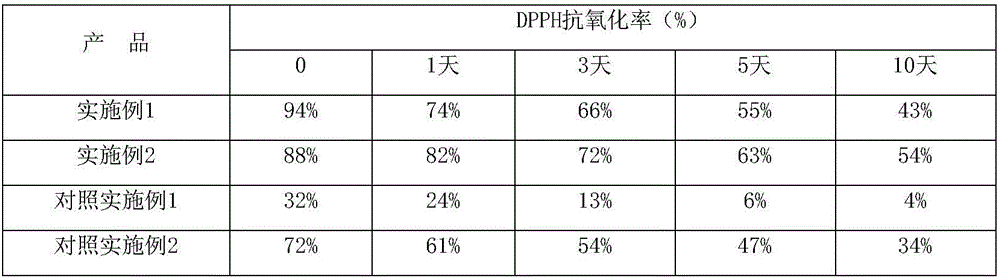

[0049] Embodiment 2: the preparation method of blueberry vinegar beverage

[0050] Take 100kg of blueberry pomace obtained in Example 1, add 100kg of water, then add 400g of pectinase, stir evenly, adjust the pH to 3.5, and after enzymolysis at room temperature for 4 hours, put it into a fermentation tank to obtain an enzymolysis solution. Add 14kg of white sugar and 8kg of yeast powder to the enzymatic hydrolysate, stir evenly, seal, and carry out anaerobic fermentation. Take 100L of fermentation broth, inoculate 6kg of acetic acid bacteria, and adjust the pH value to 5.5. Under the condition of 36-38 ℃, the fermentation was carried out with oxygen for 4 days, and 100 g of trypsin was added and incubated for 3-4 h to obtain the acetic acid feed liquid. The acetic acid feed liquid is filtered with 3 layers of gauze, and then filtered with a microporous filter with a pore size of 0.6-1.0 μm, which is the acetic acid feed liquid. 120 mL of acetic acid feed solution, 40 mL of w...

Embodiment 1

[0051] Comparative Example 1: A selenium-enriched blueberry beverage and its preparation

[0052] According to the Chinese Patent Publication No. CN104544415A, a selenium-enriched blueberry beverage and a preparation method thereof are introduced in detail. The steps are as follows: firstly prepare a chrysanthemum extract, wash the chrysanthemum with water to remove surface dust and aphids; pulverize the chrysanthemum sieve, weigh Chuju chrysanthemum, add pure water, stir and extract, and obtain Chu chrysanthemum extract after centrifugation. Preparation: Prepare 40kg of cleaned selenium-enriched blueberries and 5kg of grapes, weigh 7.5kg of Chu chrysanthemum extract, 4kg of peeled grapefruit, 10kg of honey, 6kg of white sugar, 0.8kg of wolfberry, and 45kg of purified water. Beverage preparation: (1) beating selenium-enriched blueberries, grapes, grapefruit, and wolfberry respectively, and centrifuging to obtain a supernatant for later use; (2) adding Chu chrysanthemum extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com