Electric device, washing machine containing electric device and driving and braking method thereof

An electric device, washing machine technology, applied to electromechanical devices, other washing machines, washing devices, etc., can solve the problems of power consumption, power consumption defects, time-consuming drum washing machines, etc., and achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

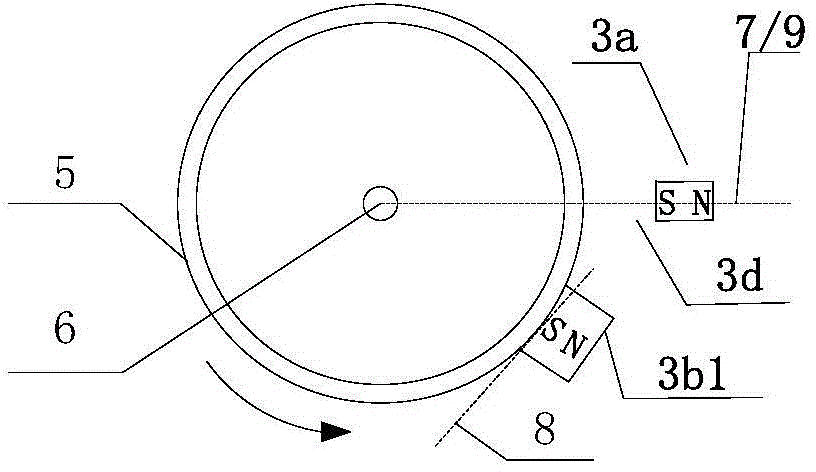

[0082] A power-saving pulsator type washing machine, the horizontal section of the frame 4 is a square with a side length of 450 mm and a height of 550 mm, and a rotary drum 5 with a circumference of 1000 mm and a height of 400 mm is selected, and the raised ribs at the bottom of the rotary drum are aligned with the conventional wave. The design of the wheel washing machine is similar; the electric device is designed as a combination of 12 rotor units 3b and 4 stator units 3a, and its structure is shown as Figure 9 Brief description: The washing machine is connected to a household 220V AC power supply, which is changed to a 48V DC power supply through a conventional transformer / rectifier device, which first meets the design requirements of safety first for household appliances.

[0083] The rotor unit is made of high-quality magnetic steel, processed into a small unit with a thickness of 2mm, a length and a width of 25mm, and the 12 permanent magnet rotor units are processed i...

Embodiment 2

[0094] On the basis of Embodiment 1, the power-on program of the power supply modulator is optimized: the T 1 The power-on time domain is set to 5 stages of current with the same power-on time but the current intensity decreases regularly, and the power-on intensity of the 5 stages is according to K*I 1 The linear relationship of / A decreases step by step, and the decrease coefficient K is 0.8, that is, T 1 The five-stage current intensity set in the power-on time domain is 25A, 20.0A, 16.0A, 12.8A, and 10.24A, respectively. The material of the rotor unit 3b is changed to conventional NdFeB.

[0095] The rest is similar to that of Embodiment 1. This embodiment can reduce the heat accumulation of the electric device, and the power saving effect is relatively good.

Embodiment 3

[0097] Change the amplitude of the pulse subset in embodiment 2 to be continuously decreasing, that is, the power modulator corresponds to T 1 When the starting current is 26A, the amplitude envelope trend in the power-on time domain is The law of decreasing, where is the dynamic angle formed by the rotor unit around the axis and the normal determined by the axis and the stator unit and the normal determined by the axis, Determined by the coincidence of the tangential direction of the rotor unit around the axis and the direction of the electromagnetic force it receives value.

[0098] In order to improve the working reliability of position signal sensing, this embodiment sets two sensing units.

[0099] In this embodiment, because the envelope of the pulse subset output by the power modulator 1 selects a more optimal time sequence decreasing relationship, the power saving effect of the washing machine is better than that of the embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com